Poboljšanje gorivnog potencijala otpadne biomase primenom hidrotermalne karbonizacije Naučni rad

Glavni sadržaj članka

Apstrakt

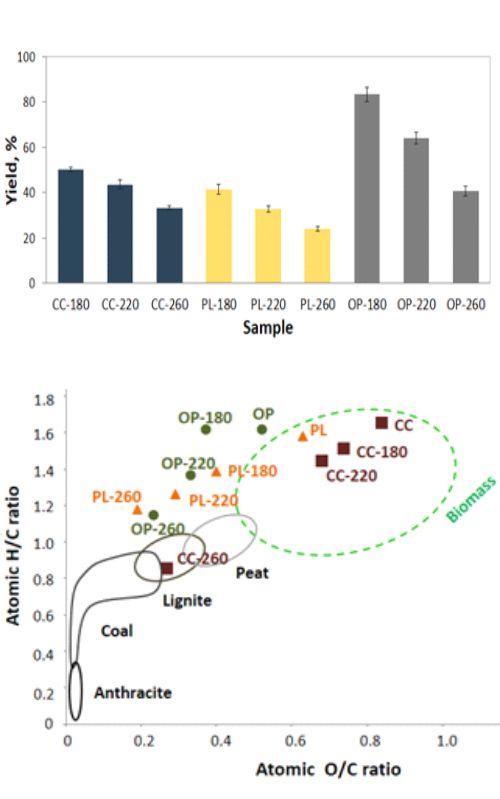

Poslednjih decenija masovna eksploatacija fosilnih goriva dovela je do sve veće potražnje za proizvodnjom energije iz obnovljivih izvora. Hidročađi dobijene hidrotermalnom karbonizacijom (engl. hydrothermal carbonization, HTC) otpadne biomase poseduju veliki potencijal kao biogorivo. U ovom radu su zato hidrotermalno karbonizovani oklasak kukuruza, listove paulovnije i kominu masline na različitim temperaturama (180, 220 i 260 oC). Glavni cilj ovog rada jeste uporedna procena uticaja HTC uslova na strukturu i gorivne karakteristie dobijenih proizvoda. Dobijeni rezultati su pokazali da se prinosi hidročađi značajno smanjuju sa porastom temperature u svim uzorcima. Sadržaj C i gornje toplotne moći rastu i dostižu najviše vrednosti u hidročađima dobijenim na 260°C, dok se sadržaj isparljivih materija smanjuje. Dalje, Van Krevelenov dijagram ukazuje da je tokom HTC procesa postignuta transformacija sirovine u proizvode slične lignitu. Naime, rezultati su pokazali da procesi dehidratacije i dekarboksilacije izazivaju intenzivnu transformaciju biomase i da hidročađi dobijene na višim temperaturama imaju značajno poboljšana gorivna svojstva i manji sadržaj isparljivih materija u poređenju sa polaznom sirovinom.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Qi R, Xu Z, Zhou Y, Zhang D, Sun Z, Chen W, Xiong M. Clean solid fuel produced from cotton textiles waste through hydrothermal carbonization with FeCl3: Upgrading the fuel quality and combustion characteristics. Energy. 2021; 214: 118926 https://doi.org/10.1016/j.energy.2020.118926

Kabakcı SB and Baran SS. Hydrothermal carbonization of various lignocellulosics: Fuel characteristics of hydrochars and surface characteristics of activated hydrochars. Waste Manage. 2019; 100: 259-268 https://doi.org/10.1016/j.wasman.2019.09.021

Kambo SH and Dutta A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl Energy. 2014; 135: 182-191 https://doi.org/10.1016/j.apenergy.2014.08.094

Petrović J, Perišić N, Dragišić Maksimović J, Maksimović V, Kragović M, Stojanović M, Laušević M, Mihajlović M. Hydrothermal conversion of grape pomace: Detailed characterization of obtained hydrochar and liquid phase. J Anal Appl Pyrol. 2016; 118: 267-277 https://doi.org/10.1016/j.jaap.2016.02.010

Mihajlović M, Petrović J, Maletić S, Kragulj Isakovski M, Stojanović M, Lopičić Z, Trifunović S. Hydrothermal carbonization of Miscanthus × giganteus: Structural and fuel properties of hydrochars and organic profile with the ecotoxicological assessment of the liquid phase. Energy Convers Manage. 2018; 159: 254-263 https://doi.org/10.1016/j.enconman.2018.01.003

Pauline AL and Joseph K. Hydrothermal carbonization of organic wastes to carbonaceous solid fuel –A review of mechanisms and process parameters. Fuel. 2020; 279: 118472. https://doi.org/10.1016/j.fuel.2020.118472

Reza MT, Andert J, Wirth B, Busch D, Pielert J, Lynam JG, Mumme J. Hydrothermal Carbonization of Biomass for Energy and Crop Production. Appl Bioenergy. 2014; 1: 11-29 https://doi.org/10.2478/apbi-2014-0001

Wang T, Zhai Y, Zhu Y, Li C, Zeng G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: process conditions, fundamentals, and physicochemical properties. Renew Sustain Energy Rev. 2018; 90: 223-247 https://doi.org/10.1016/j.rser.2018.03.071

Funke A and Ziegler F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuel Bioprod Biorefin. 2010; 4: 160-177 https://doi.org/10.1002/bbb.198

Cao X, Ro KS, Libra JA, Kammann CI, Lima I, Berge N, Li L, Li Y, Chen N, Yang J, Deng B, Mao J. Effects of Biomass Types and Carbonization Conditions on the Chemical Characteristics of Hydrochars. J Agric Food Chem. 2013; 61: 9401-9411 https://doi.org/10.1021/jf402345k

Jain A, Balasubramanian R, Srinivasan MP. Tuning hydrochar properties for enhanced mesopore development in activated carbon by hydrothermal carbonization. Micropor Mesopor Mat. 2015; 203: 178-185 https://doi.org/10.1016/j.micromeso.2014.10.036

Zhang L, Wang Q, Wang B, Yang G, Lucia LA, Chen J. Hydrothermal carbonization of corncob residues for hydrochar production. Energy Fuels. 2015; 29: 872-876 https://doi.org/10.1021/ef502462p

Fuertes AB and Sevilla M. Hierarchical microporous/mesoporous carbon nanosheets for high-performance supercapacitors. ACS Appl Mater Interf. 2015; 7: 4344-4353 https://doi.org/10.1021/am508794f

Petrović J, Stojanović M, Milojković J, Petrović M, Šoštarić T, Laušević M, Mihajlovć M. Alkali modified hydrochar of grape pomace as a perspective adsorbent of Pb2+ from aqueous solution. J Environ Manage. 2016; 182: 292–300. https://doi.org/10.1016/j.jenvman.2016.07.081

Azzaz AA, Jeguirim M, Kinigopoulou V, Doulgeris C, Goddard ML, Jellali S, Matei Ghimbeu C. Olive mill wastewater: From a pollutant to green fuels, agricultural and water source and bio-fertilizer-Hydrothermal carbonization. Sci Total Environ. 2020; 733: 139314 https://doi.org/10.1016/j.scitotenv.2020.139314

Kim D, Lee K, Park KY. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel. 2014; 130: 120-125 https://doi.org/10.1016/j.fuel.2014.04.030

Lu X, Ma X, Chen X. Co-hydrothermal carbonization of sewage sludge and lignocellulosic biomass: Fuel properties and heavy metal transformation behavior of hydrochars. Energy. 2021; 221: 119896 https://doi.org/10.1016/j.energy.2021.119896

Afolabi OOD, Sohail M, Cheng YL. Optimisation and characterisation of hydrochar production from spent coffee grounds by hydrothermal carbonization. Renew Energy. 2020; 147: 1380-1391 https://doi.org/10.1016/j.renene.2019.09.098

Kojić M, Petrović J, Petrović M, Stanković S, Porobić S, Marinović-Cincović M, Mihajlović M. Hydrothermal carbonization of spent mushroom substrate: Physicochemical characterization, combustion behavior, kinetic and thermodynamic study. J Anal Appl Pyrol. 2021; 155: 105028 https://doi.org/10.1016/j.jaap.2021.105028

Wang T, Zhai Y, Zhu Y, Gan X, Zheng L, Peng C, Wang B, Li C, Zeng G. Evaluation of the clean characteristics and combustion behavior of hydrochar derived from food waste towards solid biofuel production. Bioresour Technol. 2018; 266: 275-283 https://doi.org/10.1016/j.biortech.2018.06.093

Mendoza Martinez CL, Sermyagina E, Saari J, de Jesus MS, Cardoso M, de Almeida GM, Vakkilainen E. Hydrothermal carbonization of lignocellulosic agro-forest based biomass residues. Biomass Bioenergy. 2021; 147: 106004 https://doi.org/10.1016/j.biombioe.2021.106004

Sharma HB, Panigrahi S, Dubey BK. Hydrothermal carbonization of yard waste for solid bio-fuel production: Study on combustion kinetic, energy properties, grindability and flowability of hydrochar. Waste Manage. 2019; 91: 108-119 https://doi.org/10.1016/j.wasman.2019.04.056

Ischia G, Fiori L, Gao L, Goldfarb JL. Valorizing municipal solid waste via integrating hydrothermal carbonization and downstream extraction for biofuel production. J Clean Prod. 2021; 289: 125781 https://doi.org/10.1016/j.jclepro.2021.125781

Santos Santana M, Pereira Alves R, da Silva Borges WM, Francisquini E, Guerreiro MC. Hydrochar production from defective coffee beans by hydrothermal carbonization. Bioresour Technol. 2020; 300: 122653 https://doi.org/10.1016/j.biortech.2019.122653

Wang L, Li A, Chang Y. Hydrothermal treatment coupled with mechanical expression at increased temperature for excess sludge dewatering: Heavy metals, volatile organic compounds and combustion characteristics of hydrochar. Chem Eng J. 2016; 297: 1-10 https://doi.org/10.1016/j.cej.2016.03.131

McKendry P. Energy production from biomass (part 2): conversion technologies. Bioresour Technol. 2002; 83: 47-57 https://doi.org/10.1016/S0960-8524(01)00119-5

Ahmad M and Subawi H. New Van Krevelen diagram and its correlation with the heating value of biomass. Res J Agric Environ Manage. 2013; 2: 295-301 http://apexjournal.org/rjaem/archive/2013/Oct/fulltext/Ahmad%20and%20Subawi.pdf

Kim D, Lee K, Park KY. Upgrading the characteristics of biochar from cellulose, lignin, and xylan for solid biofuel production from biomass by hydrothermal carbonization. J Ind Eng Chem. 2016; 42: 95-100 https://doi.org/10.1016/j.jiec.2016.07.037

He C, Giannis A, Wang JY. Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl Energy. 2013; 111: 257-266 https://doi.org/10.1016/j.apenergy.2013.04.084

Akarsu K, Duman G, Yilmazer A, Keskin T, Azbar N, Yanik J. Sustainable valorization of food wastes into solid fuel by hydrothermal Carbonization. Bioresour Technol. 2019; 292: 121959 https://doi.org/10.1016/j.biortech.2019.121959