Korišćenje polimernog otpada u proizvodnji keramike za oblaganje napravljene od staklene šljake Stručni rad

Glavni sadržaj članka

Apstrakt

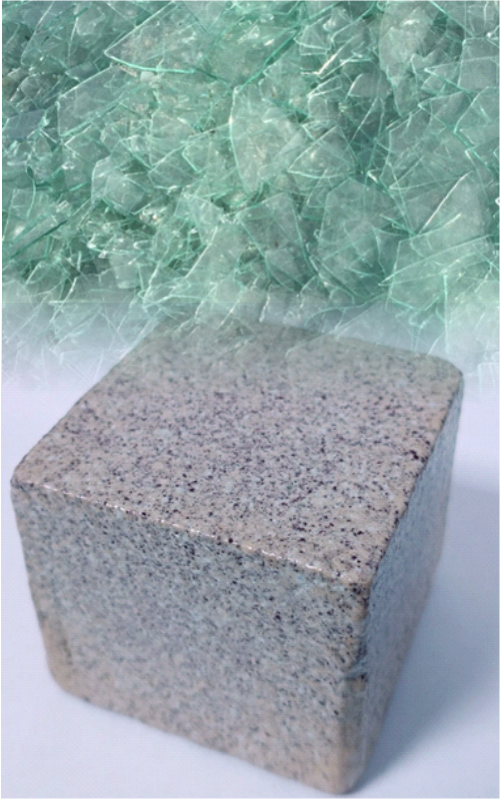

U radu su predstavljeni rezultati razvoja keramičkog materijala za oblaganje proizvedenog od gline niske plastičnosti uz dodatak borne kiseline i staklene šljake poreklom od ravnog prozorskog stakla, za primenu za sinterovanje u tečnoj fazi i postizanje efekta samoglaziranja površine. Dodatno je kao zapaljivi aditiv uveden polimerni otpad, otpad od potrošenih neplastificiranih PVC proizvoda. Rezultati istraživanja pokazuju da osnovna svojstva proizvedene keramike zavise od količine polimernog otpada dodatog u smesu, pri čemu su borna kiselina i staklena šljaka dodati u količinama koje obezbeđuju maksimalnu moguću čvrstoću i otpornost na mraz. Određena je optimalna količina polimernog otpada, što omogućava proizvodnju materijala koji ispunjava zahteve za keramičke proizvode za oblaganje i kvalifikuje se kao uslovno efikasan u pogledu termotehničkih karakteristika. Dobijeni sastav smese omogućava zajedničko korišćenje polimernog i staklenog otpada, uz istovremeno proširenje sirovinske baze i asortimana proizvoda za proizvodnju keramike za oblaganje.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Autorstvo 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

alova I, Torlova A, Pikalov E, Selivanov O. The Use of Polymer and Glass Waste to Obtain a Self-Glazing Facing Ceramic. Ecol Ind Russ. 2019; 23(11): 38-42. https://doi.org/10.18412/1816-0395-2019-11-38-42

[2] Krishnan AK, Wong YC, Zhang Z, Arulrajah A. A transition towards circular economy with the utilisation of recycled fly ash and waste materials in clay, concrete and fly ash bricks: A review. J Build Eng. 2024; 98: 111210. https://doi.org/10.1016/j.jobe.2024.111210

[3] Shi X, Liao Q, Chen K, Wang Y, Liu L, Wang F, Zhu H, Zhang L, Liu C. Foaming process and thermal insulation properties of foamed glass-ceramics prepared by recycling muti-solid wastes. Constr Build Mater. 2025; 466: 140270. https://doi.org/10.1016/j.conbuildmat.2025.140270

[4] Vitkalova I, Torlova A, Pikalov E, Selivanov O. Energy Efficiency Improving of Construction Ceramics, Applying Polymer Waste. Adv Intell Syst Comput. 2019; 983: 786-794. https://doi.org/10.1007/978-3-030-19868-8_77

[5] Martínez-Narro G, Hassan S, Phan AN. Chemical recycling of plastic waste for sustainable polymer manufacturing. J Environ Chem Eng. 2024; 12(2): 112323. https://doi.org/10.1016/j.jece.2024.112323

[6] Al-Mansour A, Xu C, Yang R, Dai Y, Dang N, Lan Y, Zhang M, Fu C, Gong F, Zeng Q. Unleashing high-volume waste plastic recycling in sustainable cement mortar with synergistic matrix enabled by in-situ polymerization. Constr Build Mater. 2024; 447: 138031. https://doi.org/10.1016/j.conbuildmat.2024.138031

[7] Sánchez-Rivera KL, Zhou P, Radkevich E, Sharma A, Bar-Ziv E, Van Lehn RC, Huber GW. A solvent-targeted recovery and precipitation scheme for the recycling of up to ten polymers from post-industrial mixed plastic waste. Waste Manage. 2025; 194: 290-297. https://doi.org/10.1016/j.wasman.2025.01.022

[8] Anuar SZK, Nordin AH, Husna SMR, Yusoff AH, Paiman SH, Noor SFM, Nordin ML, Ali SN, Ismail YMNS. Recent advances in recycling and upcycling of hazardous plastic waste: A review. J Environ Manage. 2025; 380: 124867. https://doi.org/10.1016/j.jenvman.2025.124867

[9] Vitkalova I, Torlova A, Pikalov E, Selivanov O. The Development of Energy Efficient Facing Composite Material Based on Technogenic Waste. Adv Intell Syst Comput. 2019; 983: 778-785. https://doi.org/10.1007/978-3-030-19868-8_76

[10] Liu X, Ye Z, Lu J-X, Xu S, Hsu S-C, Poon CS. Comparative LCA-MCDA of high-strength eco-pervious concrete by using recycled waste glass materials. J Clean Prod. 2024; 479: 144048. https://doi.org/10.1016/j.jclepro.2024.144048

[11] Yuan X, Wang J, Song Q, Xu Z. Integrated assessment of economic benefits and environmental impact in waste glass closed-loop recycling for promoting glass circularity. J Clean Prod. 2024; 444: 141155. https://doi.org/10.1016/j.jclepro.2024.141155

[12] Pavlycheva EA, Pikalov ES, Selivanov OG. Glazing effect for producing environmentally friendly ceramics for cladding applications. Hem Ind. 2021; 75: 167-173. https://doi.org/10.2298/HEMIND210112017

[13] Filippova LS, Akimova AS, Pikalov ES. Application of Cryolite for Liquid-Phase Sintering of Facing Ceramic Based on Low-Plasticity Clay. Inorg Mater: Appl Res. 2025; 16(1): 98-102. https://doi.org/10.1134/S2075113324701405

[14] GOST 18704-78 Boric acid. Technical conditions. Reissue (April 1993) with changes No. 1, 2, 3. 1993. https://meganorm.ru/Data2/1/4294834/4294834571.pdf (In Russian)

[15] GOST 530-2012 Brick and stone ceramic General technical conditions. 2013. https://files.stroyinf.ru/Data2/1/4293782/4293782555.pdf (In Russian)