Polymer waste utilization in manufacturing facing ceramics, produced using cullet Technical paper

Main Article Content

Abstract

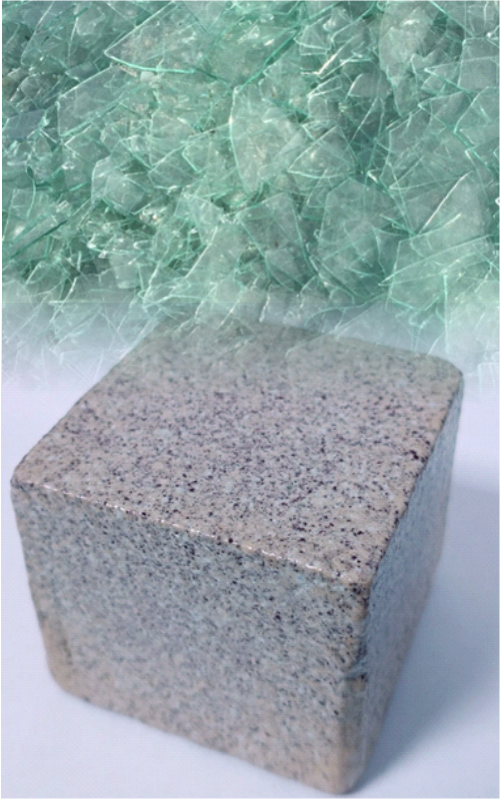

The paper presents results on the development of a facing ceramic material produced from the low-plasticity clay with the addition of boric acid and flat window glass cullet, which serve for liquid-phase sintering and achieving a surface self-glazing effect. Additionally, polymer waste, in particular, waste from consumed non-plasticized PVC products, was introduced as a combustible additive. The research results show how the basic properties of the produced ceramics depend on the polymer waste amount added to the batch, with boric acid and cullet included in quantities that provide the maximum possible strength and frost resistance. The optimal polymer waste amount was determined, enabling production of a material that meets the requirements for ceramic facing products and qualifies as conditionally effective in terms of thermal engineering characteristics. The resulting batch composition enables the joint utilization of polymer and glass waste, while simultaneously expanding the raw material base and product range for facing ceramics production.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

alova I, Torlova A, Pikalov E, Selivanov O. The Use of Polymer and Glass Waste to Obtain a Self-Glazing Facing Ceramic. Ecol Ind Russ. 2019; 23(11): 38-42. https://doi.org/10.18412/1816-0395-2019-11-38-42

[2] Krishnan AK, Wong YC, Zhang Z, Arulrajah A. A transition towards circular economy with the utilisation of recycled fly ash and waste materials in clay, concrete and fly ash bricks: A review. J Build Eng. 2024; 98: 111210. https://doi.org/10.1016/j.jobe.2024.111210

[3] Shi X, Liao Q, Chen K, Wang Y, Liu L, Wang F, Zhu H, Zhang L, Liu C. Foaming process and thermal insulation properties of foamed glass-ceramics prepared by recycling muti-solid wastes. Constr Build Mater. 2025; 466: 140270. https://doi.org/10.1016/j.conbuildmat.2025.140270

[4] Vitkalova I, Torlova A, Pikalov E, Selivanov O. Energy Efficiency Improving of Construction Ceramics, Applying Polymer Waste. Adv Intell Syst Comput. 2019; 983: 786-794. https://doi.org/10.1007/978-3-030-19868-8_77

[5] Martínez-Narro G, Hassan S, Phan AN. Chemical recycling of plastic waste for sustainable polymer manufacturing. J Environ Chem Eng. 2024; 12(2): 112323. https://doi.org/10.1016/j.jece.2024.112323

[6] Al-Mansour A, Xu C, Yang R, Dai Y, Dang N, Lan Y, Zhang M, Fu C, Gong F, Zeng Q. Unleashing high-volume waste plastic recycling in sustainable cement mortar with synergistic matrix enabled by in-situ polymerization. Constr Build Mater. 2024; 447: 138031. https://doi.org/10.1016/j.conbuildmat.2024.138031

[7] Sánchez-Rivera KL, Zhou P, Radkevich E, Sharma A, Bar-Ziv E, Van Lehn RC, Huber GW. A solvent-targeted recovery and precipitation scheme for the recycling of up to ten polymers from post-industrial mixed plastic waste. Waste Manage. 2025; 194: 290-297. https://doi.org/10.1016/j.wasman.2025.01.022

[8] Anuar SZK, Nordin AH, Husna SMR, Yusoff AH, Paiman SH, Noor SFM, Nordin ML, Ali SN, Ismail YMNS. Recent advances in recycling and upcycling of hazardous plastic waste: A review. J Environ Manage. 2025; 380: 124867. https://doi.org/10.1016/j.jenvman.2025.124867

[9] Vitkalova I, Torlova A, Pikalov E, Selivanov O. The Development of Energy Efficient Facing Composite Material Based on Technogenic Waste. Adv Intell Syst Comput. 2019; 983: 778-785. https://doi.org/10.1007/978-3-030-19868-8_76

[10] Liu X, Ye Z, Lu J-X, Xu S, Hsu S-C, Poon CS. Comparative LCA-MCDA of high-strength eco-pervious concrete by using recycled waste glass materials. J Clean Prod. 2024; 479: 144048. https://doi.org/10.1016/j.jclepro.2024.144048

[11] Yuan X, Wang J, Song Q, Xu Z. Integrated assessment of economic benefits and environmental impact in waste glass closed-loop recycling for promoting glass circularity. J Clean Prod. 2024; 444: 141155. https://doi.org/10.1016/j.jclepro.2024.141155

[12] Pavlycheva EA, Pikalov ES, Selivanov OG. Glazing effect for producing environmentally friendly ceramics for cladding applications. Hem Ind. 2021; 75: 167-173. https://doi.org/10.2298/HEMIND210112017

[13] Filippova LS, Akimova AS, Pikalov ES. Application of Cryolite for Liquid-Phase Sintering of Facing Ceramic Based on Low-Plasticity Clay. Inorg Mater: Appl Res. 2025; 16(1): 98-102. https://doi.org/10.1134/S2075113324701405

[14] GOST 18704-78 Boric acid. Technical conditions. Reissue (April 1993) with changes No. 1, 2, 3. 1993. https://meganorm.ru/Data2/1/4294834/4294834571.pdf (In Russian)

[15] GOST 530-2012 Brick and stone ceramic General technical conditions. 2013. https://files.stroyinf.ru/Data2/1/4293782/4293782555.pdf (In Russian)