Uticaj metode izluživanja na uklanjanje teških metala iz letećeg pepela Naučni rad

Glavni sadržaj članka

Apstrakt

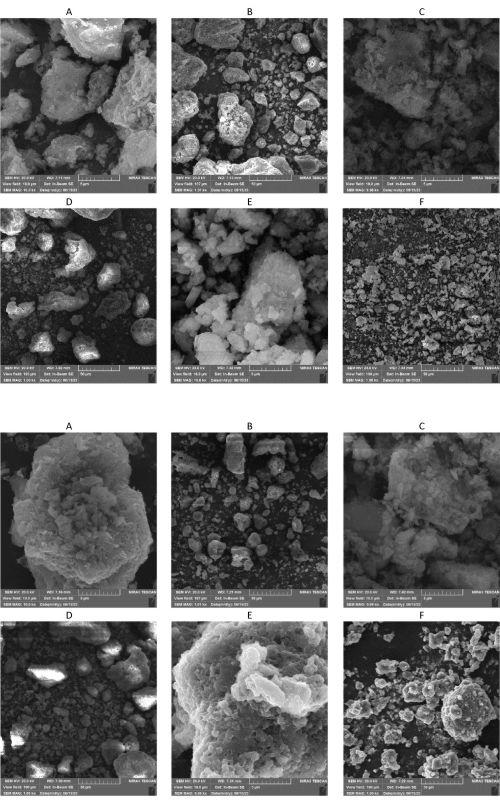

Uklanjanje teških metala (Cr, Mn, Co, Ni, Cu, Zn, As, Cd i Pb) iz elektrofilterskog pepela proučavano je korišćenjem metoda kiselog luženja i vlažne oksidacije. Paralelno je primenjena i kisela digestija uz pomoć mikrotalasne pećnice za određivanje pseudoukupnih koncentracija teških metala u cilju procene efikasnosti luženja. Multivarijantna statistika (Pearsonova korelacija, analiza glavnih komponenti i hijerarhijska klaster analiza) pokazala je dve dominantne grupe elemenata u zavisnosti od njihovih karakteristika i afiniteta prema čvrstoj fazi pepela. Grupe I (Cr, Zn, Mn, Co i Ni) i II (Pb, As, Cd i Cu) su međusobno diskriminisane. Pokazalo se da je metoda vlažne oksidacije prikladnija od kiselog luženja jer je smanjenje koncentracija metala bilo 30-75 % u poređenju sa 12-25 % dobijenih kiselom digestijom. Takođe je ispitan uticaj tretmana letećeg pepela na karakteristike čvrstog ostatka metodama rendgenske difrakcije i skenirajuće elektronske mikroskopije. Ovim metodama su otkrivene promene na površini i u strukturi letećeg pepela nakon tretmana vlažnom oksidacijom. Vlažna oksidacija se može smatrati kao moguća metoda za tretman u cilju uklanjanje teških metala iz letećeg pepela, obezbeđujući materijal koji bi se mogao dalje koristiti i smanjujući rizik od zagađenja izazvanog odlaganjem letećeg pepela.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Science Fund of the Republic of Serbia

Grant numbers 7743343

Reference

Šerović R, Jelić I, Matić B, Savić A. Utilization of solidified industrial hazardous waste in construction: A case study. Hem Ind. 2023; 77(2): 137-146 https://doi.org/10.2298/HEMIND222610001S.

Vukićević M, Popović Z, Despotović J, Lazarević L. Fly ash and slag utilization for the serbian railway substructure. Transport. 2018; 33(2): 389-396 https://doi.org/10.3846/16484142.2016.1252427.

Tasić AM, Sredović Ignjatović ID, Ignjatović LM, Ilić MA, Antić MP. Comparison of sequential and single extraction in order to estimate the environmental impact of metals from fly ash. J Serb Chem Soc. 2016; 81(9): 1081-1096 https://doi.org/10.2298/JSC160307038T.

Đorđević D, Stanković M, Krstić N, Dimitrijević V, Anastasijević N, Đorđević M, Nikolić M. Geochemical analysis of Kostolac power plant fly ash: working and living environment influence aspect. Saf Eng. 2018; 8(1): 15-20 https://doi.org/10.7562/SE2018.8.01.03.

Đolić M, Ćujić M, Stanišić T, Čičkarić D, Ristić M, Perić Grujić A. Contribution to the Serbian coal ranking and fly ash characterization using Pb isotopic ratio. Metall Mater Eng. 2022; 28(4): 675-684 https://doi.org/10.56801/MME931.

Slavković-Beškoski L, Ignjatović L, Bolognesi G, Maksin D, Savić A, Vladisavljević G, Onjia A. Dispersive Solid-Liquid Microextraction Based on the Poly(HDDA)/Graphene Sorbent Followed by ICP-MS for the Determination of Rare Earth Elements in Coal Fly Ash Leachate. Metals (Basel). 2022; 12(5): 791 https://doi.org/10.3390/met12050791.

Buha Marković JZ, Marinković AD, Savić JZ, Mladenović MR, Erić MD, Marković ZJ, Ristić MĐ. Risk Evaluation of Pollutants Emission from Coal and Coal Waste Combustion Plants and Environmental Impact of Fly Ash Landfilling. Toxics. 2023; 11(4): 396 https://doi.org/10.3390/toxics11040396.

Buha-Marković J, Marinković A, Savić J, Krstić A, Savić A, Ristić M. Health risk assessment of potentially harmful substances from fly ashes generated by coal and coal waste combustion. J Serb Chem Soc. 2023; 88(11): 1161-1173 https://doi.org/10.2298/JSC220130048M.

Petronijević N, Radovanović D, Štulović M, Sokić M, Jovanović G, Kamberović Ž, Stanković S, Stopić S, Onjia A. Analysis of the Mechanism of Acid Mine Drainage Neutralization Using Fly Ash as an Alternative Material: A Case Study of the Extremely Acidic Lake Robule in Eastern Serbia. Water (Switzerland). 2022; 14(20): 3244 https://doi.org/10.3390/w14203244.

Trivunac K, Vukčević M, Maletić M, Karić N, Pejić B, Perić-Grujić A. Waste materials as adsorbents for heavy metals removal from water: Comparative analysis of modification techniques. Tekst Ind. 2023; 71(1): 4-10 https://doi.org/10.5937/tekstind2301004T.

Wang N, Sun X, Zhao Q, Yang Y, Wang P. Leachability and adverse effects of coal fly ash: A review. J Hazard Mater. 2020; 396: 122725 https://doi.org/10.1016/j.jhazmat.2020.122725.

Bruker-AXS (2013). Crystallography Open Database for DIFFRAC.EVA. https://www.bruker.com/products/x-ray-diffraction-and-elemental-analysis/x-ray-diffraction/xrd-software/eva/cod.html

Powder Diffraction File: PDF-2 (Database), International Center for Diffraction Data (ICDD), Newtown Square, Pennsylvania, USA, 2008.

ASTM-C 618-15: Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete. 2015

Moreno N, Querol X, Andrés JM, Stanton K, Towler M, Nugteren H, Janssen-Jurkovicová M, Jones R. Physico-chemical characteristics of European pulverized coal combustion fly ashes. Fuel. 2005; 84(11): 1351-1363 https://doi.org/10.1016/j.fuel.2004.06.038 .

Strzałkowska E. Morphology, chemical and mineralogical composition of magnetic fraction of coal fly ash. Int J Coal Geol. 2021; 240: 103746 https://doi.org/10.1016/j.coal.2021.103746.

Wei Q, Song W. Mineralogical and chemical characteristics of coal ashes from two high-sulfur coal-fired power plants in Wuhai, Inner Mongolia, China. Minerals 2020; 10(4): 323 https://doi.org/10.3390/min10040323.

Dahl O, Nurmesniemi H, Pöykiö R, Watkins G. Heavy metal concentrations in bottom ash and fly ash fractions from a large-sized (246 MW) fluidized bed boiler with respect to their Finnish forest fertilizer limit values. Fuel Process Technol. 2010; 91(11): 1634-1639 https://doi.org/10.1016/j.fuproc.2010.06.012.

Tang Q, Liu G, Zhou C, Sun R. Distribution of trace elements in feed coal and combustion residues from two coal-fired power plants at Huainan, Anhui, China. Fuel. 2013; 107: 315-322 https://doi.org/10.1016/j.fuel.2013.01.009.

Dai S, Zhao L, Peng S, Chou C-L, Wang X, Zhang Y, Li D, Sun Y. Abundances and distribution of minerals and elements in high-alumina coal fly ash from the Jungar Power Plant, Inner Mongolia, China. Int J Coal Geol. 2010; 81(4): 320-332 https://doi.org/10.1016/j.coal.2009.03.005.

da Silva EB, Li S, de Oliveira LM, Gress J, Dong X, Wilkie AC, Townsend T, Ma LQ. Metal leachability from coal combustion residuals under different pHs and liquid/solid ratios. J Hazard Mater. 2018; 341 (September): 66-74 https://doi.org/10.1016/j.jhazmat.2017.07.010.

Ramanathan T, Ting YP. Selection of wet digestion methods for metal quantification in hazardous solid wastes. J Environ Chem Eng. 2015; 3(3): 1459-1467 https://doi.org/10.1016/j.jece.2015.05.006.

Ramakrishna C, Thenepalli T, Nam SY, Kim C, Ahn JW. The brief review on coal origin and distribution of rare earth elements in various coal ash samples. KSEE. 2018; 27(2): 61-69 https://doi.org/10.5855/ENERGY.2018.27.2.061.

Hredzák S, Tomanec R, Matik M, Šepelák V, Václavíková M. Magnetic separation and analysis of products obtained from coal-fired power plant fly ashes of Nikola Tesla B (Serbia). J Min Met. 2006; 42 A: 55-68 https://www.jmma.tfbor.bg.ac.rs/Volumes/2006/06.pdf.

Šešlija M, Rosić A, Radović N, Vasić M, Đogo M, Jotić M. Physiproperties of fly ash and slag from the power plants. Geol Croat. 2016; 69(3): 317-324 https://doi.org/10.4154/gc.2016.26.

Tabachnick BG, Fidel SL. Using multivariate statistics. 7th ed., New York, NY: Pearson; 2018. ISBN 978-0134790541

Kaiser HF, A second generation little jiffy. Psychometrika. 1970; 35(4): 401-415 https://doi.org/10.1007/BF02291817.

Bartlett MS. A note on the multiplying factor for various chi square approximations. J R Stat Soc, B:Stat. 1954; 16: 296-298 https://doi.org/10.1111/j.2517-6161.1954.tb00174.x.