SYSTEM DEVELOPMENT FOR MONITORING THE PRODUCTION PROCESS OF FREEZE-DRIED SAMPLES: A SIMPLE AND LOW-COST APPROACH

Original scientific paper

DOI:

https://doi.org/10.2298/CICEQ220821016DKeywords:

lyophilization, drying, freezing, heating temperature, Arduino, avocadoAbstract

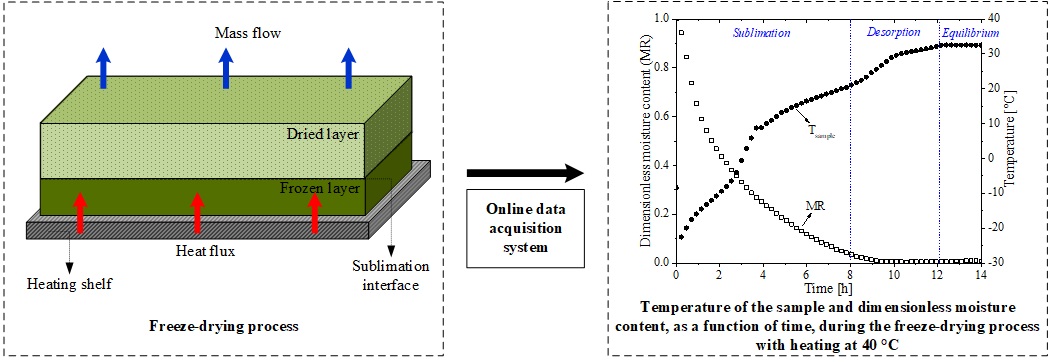

The data acquisition from the freeze-drying process is important for obtaining freeze-dried samples with the desired final moisture content under various operating conditions. The current study extensively presents a simple and low-cost methodology for implementing a data acquisition system in a laboratory-scale freeze dryer. The results showed that higher drying temperatures (40 °C) increased the errors involved in measuring the mass of material; nevertheless, the application of correction blank curves statistically significantly reduced those errors. In general, the system developed provided precise and accurate measurements of the temporal changes in the sample mass and temperature, and chamber pressure variations, allowing monitoring of the production process of freeze-dried samples with low final moisture contents.

References

G. Caliskan, S.N. Dirim, Heat Mass Transfer 53 (2017) 2129—2141. https://doi.org/10.1007/s00231-017-1967-x.

Y. Wang, X. Li, X. Chen, B. Li, X. Mao, J. Miao, C. Zhao, L. Huang, W. Gao, Chem. Eng. Process. 129 (2018) 84—94. https://doi.org/10.1016/j.cep.2018.03.020.

E. Lopez-Quiroga, L.T. Antelo, A.A. Alonso, J. Food Eng. 111 (2012) 655—666. https://doi.org/10.1016/j.jfoodeng.2012.03.001.

L.G. Marques, M.C. Ferreira, J.T. Freire, Chem. Eng. Process. 46 (2007) 451—457. https://doi.org/10.1016/j.cep.2006.04.011.

R.L. Monteiro, B.A.M. Carciofi, A. Marsaioli, J.B. Laurindo, J. Food Eng. 166 (2015) 276—284. https://doi.org/10.1016/j.jfoodeng.2015.06.029.

A.S. Mujumdar, Handbook of Industrial Drying, CRC Press, Boca Raton, (2014), p. 1352. https://doi.org/10.1080/07373938808916399.

X.C. Tang, M.J. Pikal, Pharm. Res. 21 (2004) 191—200. https://doi.org/10.1023/B:PHAM.0000016234.73023.75.

V. Dal-Bó, J.T. Freire, Food Control. 132 (2022) 108526. https://doi.org/10.1016/j.foodcont.2021.108526.

A. Carullo, A. Vallan, Measurement 45 (2012) 1706—1712. https://doi.org/10.1016/j.measurement.2012.04.017.

G. Tribuzi, J.B. Laurindo, Dry. Technol. 32 (2014) 1119—1124. https://doi.org/10.1080/07373937.2014.886258.

V. Kirrmaci, H. Usta, T. Menlik, Dry. Technol. 26 (2008) 1570—1576. https://doi.org/10.1080/07373930802467037.

J.P. George, A.K. Datta, J. Food Eng. 52 (2002) 89—93. https://doi.org/10.1016/S0260-8774(01)00091-7.

T. Menlik, M.B. Özdemir, V. Kirmaci, Expert Syst. Appl. 37 (2010) 7669—7677. https://doi.org/10.1016/j.eswa.2010.04.075.

C. Moino, E. Bourlés, R. Pisano, B. Scutellà, Ind. Eng. Chem. Res. 60 (2021) 9637—9645. https://doi.org/10.1021/acs.iecr.1c00536.

S.C. Schneid, H. Gieseler, W.J. Kessler, S.A. Luthra, M.J. Pikal, AAPS PharmSciTech. 12 (2011) 379—387. https://doi.org/10.1208/s12249-011-9600-7.

X. (Charlie) Tang, S.L. Nail, M.J. Pikal, Pharm. Res. 22 (2005) 685—700. https://doi.org/10.1007/s11095-005-2501-2.

P. Chouvenc, S. Vessot, J. Andrieu, P. Vacus, Dry. Technol. 22 (2004) 1577—1601. https://doi.org/10.1081/DRT-200025605.

R. Daoussi, S. Vessot, J. Andrieu, O. Monnier, Chem. Eng. Res. Des. 87 (2009) 899—907. https://doi.org/10.1016/j.cherd.2008.09.007.

S.A. Velardi, H. Hammouri, A.A. Barresi, Chem. Eng. Res. Des. 87 (2009) 1409—1419. https://doi.org/10.1016/j.cherd.2009.03.011.

C. Vilas, A.A. Alonso, E. Balsa-Canto, E. López-Quiroga, I.C. Trelea, Processes 8 (2020) 1—21. https://doi.org/10.3390/pr8030325.

R. Pisano, Dry. Technol. 40 (2022) 140—157. https://doi.org/10.1080/07373937.2020.1774891.

A.A. Barresi, R. Pisano, D. Fissore, V. Rasetto, S.A. Velardi, A. Vallan, M. Parvis, M. Galan, Chem. Eng.

Process. Process Intensif. 48 (2009) 408—423. https://doi.org/10.1016/j.cep.2008.05.004.

A. Vallan, Instrumentation and Measurement Technology Conference, in Proceeding of IEEE Instrumentation & Measurement Technology Conference, Warsaw, Poland, (2007). p. 1—5. https://doi.org/10.1109/IMTC.2007.379000.

M.J. Pikal, S. Shah, D. Senior, J.E. Lang, J. Pharm. Sci. 72 (1983) 635—650. https://doi.org/10.1002/jps.2600720614.

C. Roth, G. Winter, G. Lee, J. Pharm. Sci. 90 (2001) 1345—1355. https://doi.org/10.1002/jps.1087.

J. Xiang, J.M. Hey, V. Liedtke, D.. Wang, Int. J. Pharm. 279 (2004) 95—105. https://doi.org/10.1016/j.ijpharm.2004.04.011.

D. Fissore, R. Pisano, A.A. Barresi, Dry. Technol. 36 (2018) 1839—1865. https://doi.org/10.1080/07373937.2018.1440590.

G. Rovero, S. Ghio, A.A. Barresi, Chem. Eng. Sci. 56 (2001) 3575—3584. https://doi.org/10.1016/S0009-2509(01)00025-2.

S. Grassini, S. Corbellini, M. Parvis, E. Angelini, F. Zucchi, Meas.: J. Int. Meas. Confed. 114 (2018) 508—514. https://doi.org/10.1016/j.measurement.2016.07.014.

V.D. Sabadoti, A.C. Miano, P.E.D. Augusto, J. Food Process. Preserv. 44 (2020) 1—10. https://doi.org/10.1111/jfpp.14769.

O.I. Obajemihi, J.O. Olaoye, J.H. Cheng, J.O. Ojediran, D.W. Sun, J. Food Process. Preserv. 45 (2021) 1—14. https://doi.org/10.1111/jfpp.15287.

A. D’Ausilio, Behav. Res. Methods 44 (2012) 305—313. https://doi.org/10.3758/s13428-011-0163-z.

A. Kilpela, Pulsed time-of-flight laser range finder techniques for fast, high precision measurement applications, University of Oulu, (2004) p. 98. https://oulurepo.oulu.fi/handle/10024/35963.

X. Li, B. Yang, X. Xie, D. Li, L. Xu, Sensors (Switzerland). 18 (2018) 1—16. https://doi.org/10.3390/s18041156.

AOAC, Official methods of analysis of Association of Official Analytical Chemists, AOAC, Arlington (1990), p. 771. ISBN 0-935584-42-0.

P. Jacobs, Thermodynamics, Imperial College Press, London (2013), p. 456. ISBN 184816971X.

W. Yang, D.E.O. III, R.O.W. III, in Formulating Poorly Water Soluble Drugs, R.O. Williams III, A. B. Watts, D. A. Miller, Springer, New York (2012), p. 646. https://doi.org/10.1007/978-1-4614-1144-4.

A. Bhushani, C. Anandharamakrishnan, in Handbook of Drying for Dairy Products, C. Anandharamakrishnan, John Wiley & Sons, Chichester (2017) p. 316. https://doi.org/10.1002/9781118930526.ch6.

O. Taskin, Heat Mass Transfer 56 (2020) 2503—2513. https://doi.org/10.1007/s00231-020-02867-0.

T. Kovacı, E. Dikmen, A.Ş. Şahin, J. Food Process Eng. 43 (2020) 1—9. https://doi.org/10.1111/jfpe.13528.

L.L. Huang, M. Zhang, A.S. Mujumdar, D.F. Sun, G.W. Tan, S. Tang, Dry. Technol. 27 (2009) 938—946. https://doi.org/10.1080/07373930902901844.

I. Dincer, M.A. Rosen, Energy, Environment and Sustainable Development, Springer, Vienna, (2012) p. 349. https://doi.org/10.1007/978-3-7091-0109-4.

Y.A. Çengel, M.A. Boles, Thermodynamics: an engineering approach, Mc Graw Hill Education, New York, (2014) p. 1024. ISBN 9780073398174.

A. Midilli, H. Kucuk, Z. Yapar, Dry. Technol. 20 (2002) 1503–1513. https://doi.org/10.1081/DRT-120005864.

T. Kopczynski, Five Factors That Can Affect Your Weighing System’s Accuracy, Hardy, San Diego, (2011). https://www.hardysolutions.com/images/uploaded/5Factors_WP_0323%20(1).pdf.

C.D. Johnson, Process Control Instrumentation Technology, Pearson Education Limited, Harlow, (2013) p. 684. ISBN 9781292026015.

A.L. Silva, M. Varanis, A.G. Mereles, C. Oliveira, J.M. Balthazar, Rev. Bras. Ensino Fis. 41 (2019). https://doi.org/10.1590/1806-9126-RBEF-2018-0206.

A.R. Gorbushin, A.A. Bolshakova, Measurement 152 (2020) 107381. https://doi.org/10.1016/j.measurement.2019.107381.

W. Hernandez, Sensors 6 (2006) 697—711. https://doi.org/10.3390/s6070697.

I. Muller, R. De Brito, C.E. Pereira, V. Brusamarello, IEEE Instrum. Meas. Mag. 13 (2010) 15—19. https://doi.org/10.1109/MIM.2010.5399212.

A. Karaus, H. Paul, Measurement 10 (1992) 133—139. https://doi.org/10.1016/0263-2241(92)90009-S.

G. Levi, M. Karel, Food Res. Int. 28 (1995) 145—151. https://doi.org/10.1016/0963-9969(95)90798-F.

M.J. Pikal, S. Shah, Int. J. Pharm. 62 (1990) 165—186. https://doi.org/10.1016/0378-5173(90)90231-R.

D.S. Souza, L.G. Marques, E. de B. Gomes, N. Narain, Dry. Technol. 33 (2015) 194—204. https://doi.org/10.1080/07373937.2014.943766.

R.J. Brandão, M.M. Prado, L.G. Marques, Defect Diffus. Forum 365 (2015) 11—16. https://doi.org/10.4028/www.scientific.net/ddf.365.11.

K. Altay, A.A. Hayaloglu, S.N. Dirim, Heat Mass Transfer 55 (2019) 2173—2184. https://doi.org/10.1007/s00231-019-02570-9.

W. Liu, M. Zhang, B. Adhikari, J. Chen, Innov. Food Sci. Emerg. Technol. 66 (2020) 102516. https://doi.org/10.1016/j.ifset.2020.102516.

X. Duan, X. Yang, G. Ren, Y. Pang, L. Liu, Y. Liu, Dry. Technol. 34 (2016) 1271—1285. https://doi.org/10.1080/07373937.2015.1099545.

X. Cao, M. Zhang, A.S. Mujumdar, Q. Zhong, Z. Wang, Ultrason. Sonochem. 40 (2018) 333—340. https://doi.org/10.1016/j.ultsonch.2017.06.014.

T. Baysal, N. Ozbalta, S. Gokbulut, B. Capar, O. Tastan, G. Gurlek, F. Engineering, M. Engineering, K. Tarihi, J. Therm. Sci. Technol. 35 (2015) 135—144. http://tibtd.org.tr/2015-1/135-144.pdf.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Vanessa Dal-Bó, Heitor Otacílio Nogueira Altino, José Teixeira Freire

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Conselho Nacional de Desenvolvimento Científico e Tecnológico

Grant numbers 140907/2017-3 -

Coordenação de Aperfeiçoamento de Pessoal de Nível Superior

Grant numbers Finance Code 001