INVESTIGATION OF THE THIN LAYER DRYING OF MICROPROPAGATED OCIMUM BASILICUM L: MODELING BY DERIVED EQUATIONS, QUALITY CHARACTERISTICS, AND ENERGY EFFICIENCY

Original scientific paper

DOI:

https://doi.org/10.2298/CICEQ220722003KKeywords:

micropropagation, O. basilicum L., thin-layer drying, modeling, energy consumption, characteristicAbstract

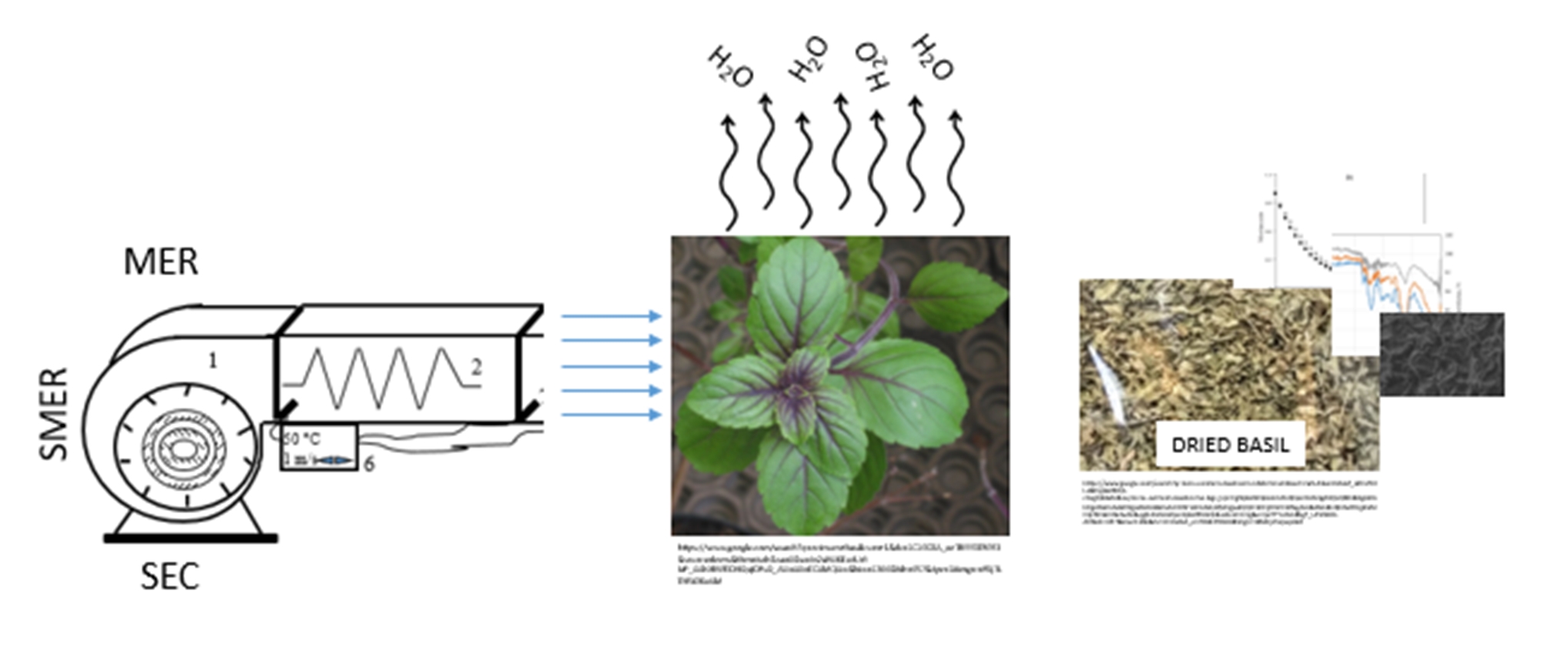

This study presents the modeling of thin layer drying of micropropagated Ocimum basilicum L., some quality characteristics of the dried product, and energy consumption analysis for the dryer used. The experimental drying data obtained from a previous article were used in the statistical analyses. Modeling studies were statistically carried out using the experimental data at a 1 m/s airflow rate and a temperature of 30 °C—50 °C. The statistical analysis showed that the Verma equation was the best-fit model with the lowest chi-square (χ2) and AIC values at all temperatures studied. From statistical analyses using derived drying models, it was found that the D9 equation having a χ2 value of 0.0146 and an AIC value of -528.0, was the best model fitting to experimental data. The total phenolic content, flavonoid, and antioxidant capacity of dried basil samples were measured as (2.538 ± 0.029) mg GAE/g, (2.017 ± 0.088) mg quercetin/g, and (2.263 ± 0.001) mmol TEAC/100 g d.w., respectively. From FTIR spectra, dried basil samples had typical functional groups. SEM images showed that a collapse in the surface of the leaves occurred. But, this collapse is not affecting the functional groups on the surface of the leaves. From energy consumption analyses, the optimum drying temperature was found to be 40 °C. The SMER, MER, and SEC values calculated from energy consumption analysis at 40 °C were 0.0043 kg/kWh, 0.0007 kg/h, and 234.81 kWh/kg, respectively.

References

J.E. Simon, M.R. Morales, W.B. Phippen, R.F. Vieira, Z. Hao, Basil: A source of aroma compounds and a popular culinary and ornamental herb, Janick J (Ed) ASHS press,Alexandria , VA, (1999), p 499.

K. Carović-Stanko, Z. Liber, V. Besendorfer, B. Javornik, B. Bohanec, I. Kolak, Z. Satovic, Plant Sys Evol Suppl 285 (2010) 13—22. https://doi.org/10.1007/s00606-009-0251-z.

S. Filip, Int. J. Clin. Nutr. Diet 3 (2017) 118. https://doi.org/10.15344/2456-8171/2017/118.

O. Makri, S. Kintzios, J. Herbs, Spices Med. Plants 13 (2008) 123—150. https://doi.org/10.1300/J044v13n03_10.

K. Dhama, K. Sharun, M.B. Gugjoo, R. Tiwari, M. Alagawany, M. Iqbal Yatoo, P. Thakur, H.M. Iqbal, W. Chaicumpa, I. Michalak, Food Rev. Int. (2021) 1—29. https://doi.org/10.1080/87559129.2021.1900230.

C. Jayasinghe, N. Gotoh, T. Aoki, S. Wada, J. Agric. Food Chem. 51 (2003) 4442—4449. https://doi.org/10.1021/jf034269o.

L.C. Chiang, L.T. Ng, P.W. Cheng, W. Chiang, C.C. Lin, Clin. Exp. Pharmacol. Physiol. 32 (2005) 811—816. https://doi.org/10.1111/j.1440-1681.2005.04270.x.

A.B. Mohammed, S. Yagi, T. Tzanova, H. Schohn, H. Abdelgadir, A. Stefanucci, A. Mollica, M.F. Mahomoodally, T.A. Adlan, G. Zengin, S. Afr. J. Bot. 132 (2020) 403—409. https://doi.org/10.1016/j.sajb.2020.06.006.

A. Aye, Y.-D. Jeon, J.-H. Lee, K.-S. Bang, J.-S. Jin, Oriental Pharmacy and Experimental Medicine 19 (2019) 217—226. https://doi.org/10.1007/s13596-019-00372-2.

N.A. Arikat, F.M. Jawad, N.S. Karam, R.A. Shibli, Sci. Hortic. (Amsterdam, Neth.) 100 (2004) 193—202. https://doi.org/10.1016/j.scienta.2003.07.006.

R.L.M. Pierik, In vitro culture of higher plants, Kluwer Academic Publisher,Boston, (1997), p.301. 0792345274.

M. Debnath, C. Malik, P.S. Bisen, Curr. Pharm. Biotechnol. 7 (2006) 33—49. DOI: 10.2174/138920106775789638.

K. Altay, A.A. Hayaloglu, S.N. Dirim, Heat Mass Transfer. 55 (2019) 2173—2184. https://doi.org/10.1007/s00231-019-02570-9.

S. Fang, Z. Wang, X. Hu, Int. J. Food Sci. Technol. 44 (2009) 1818—1824. https://doi.org/10.1111/j.1365-2621.2009.02005.x.

B. Tepe, T.K. Tepe, A. Ekinci, Chem. Ind. Chem. Eng. Q. 22 (2022) 151—159. https://doi.org/10.2298/CICEQ210126026T.

A.C. Ersan, N. Tugrul, Chem. Ind. Chem. Eng. Q. 27 (2021) 319—328. https://doi.org/10.2298/CICEQ201114050E.

M. Özcan, D. Arslan, A. Ünver, J. Food Eng. 69 (2005) 375—379. https://doi.org/10.1016/j.jfoodeng.2004.08.030.

A. Telfser, F.G. Galindo, LWT 99 (2019) 148—155. https://doi.org/10.1016/j.lwt.2018.09.062.

A. Topdemir, J. Fırat Univ. Eng. Sci. 31 (2019) 545—550. https://doi.org/10.35234/fumbd.580212.

T. Murashige, F. Skoog, Physiol. Plant. 15 (1962) 473—497. https://doi.org/10.1111/j.1399-3054.1962.tb08052.x.

C.J. Geankoplis, A.A. Hersel, D.H. Lepek, Transport processes and separation process principles, Prentice Hall Boston, (2018). ISBN 0-13-045253-X.

J.M. Coulson, J.F. Richardson, J.R. Backhurst, J.H. Harker, Chemical Engineering: Fluid flow, heat transfer and mass transfer, Pergamon press,London, (1954). ISBN: 9788181473868.

Z. Erbay, F. Icier, Crit. Rev. Food Sci. Nutr. 50 (2010) 441—

https://doi.org/10.1080/10408390802437063.

C. Ertekin, M.Z. Firat, Crit. Rev. Food Sci. Nutr. 57 (2017) 701—717. https://doi.org/10.1080/10408398.2014.910493.

Q. Liu, F. Bakker-Arkema, J. Agric. Eng. Res. 66 (1997) 275—280. https://doi.org/10.1006/jaer.1996.0145.

G.E. Page, Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin layers., Master Thesis, Purdue University(1949). 1083231995.

S. Henderson, S. Pabis, J. Agric. Eng. Res. 7 (1962) 85—89.

A. Yağcıoğlu, A. Değirmencioğlu, F. Çağatay, Drying characteristics of laurel leaves under different drying conditions, in 7th Int Congr. Agric. Mechan. Energy, (1999) 565—569.

C. Wang, R. Singh, Trans. Am. Soc. Agric. Eng. 11 (1978) 668—672.

A. Kassem, Comparative studies on thin layer drying models for wheat, 13th Int. Congr. Agric. Eng., (1998) 2—6.

M. Kalender, Constr. Build. Mater. 155 (2017) 947—955. https://doi.org/10.1016/j.conbuildmat.2017.08.094.

L. Bennamoun, L. Kahlerras, F. Michel, L. Courard, T. Salmon, L. Fraikin, A. Belhamri, A. Léonard, Int. J. Energy Eng. 3 (2013) 1—6. https://hdl.handle.net/2268/134220.

H. Akaike, Factor analysis and AIC, Springer,New York, (1987). ISBN 0-387-98355-4.

F.P. Gomes, R. Osvaldo, E.P. Sousa, D.E. de Oliveira, F.R.d. Araújo Neto, Revista Brasileira de Engenharia Agrícola e Ambiental 22 (2018) 499—505. https://doi.org/10.1590/1807-1929/agriambi.v22n12p866-871.

V.L. Singleton, J.A. Rossi, Am. J. Enol. Vitic. 16 (1965) 144—158. DOI: 10.5344/ajev.1965.16.3.144.

J. Lamaison, C. Petitjean-Freytet, A. Carnat, Annales Pharmaceutiques Francaises (France) 48 (1990) 103—108.

N.J. Miller, A.T. Diplock, C.A. Rice-Evans, J. Agric. Food Chem. 43 (1995) 1794—1801. https://doi.org/10.1021/jf00055a009.

Y. Gökçe, H. Kanmaz, B. Er, K. Sahin, A. Hayaloglu, Food Bioscience 43 (2021) 101228. https://doi.org/10.1016/j.fbio.2021.101228.

W. Brand-Williams, M.-E. Cuvelier, C. Berset, LWT-Food science and Technology 28 (1995) 25—30. https://doi.org/10.1016/S0023-6438(95)80008-5.

H. Toğrul, J. Food Eng. 77 (2006) 610—619. https://doi.org/10.1016/j.jfoodeng.2005.07.020.

Y. Siti Mahirah, M. Rabeta, R. Antora, Food Res. 2 (2018) 421—428. https://doi.org/10.26656/fr.2017.2(5).

R. Oonsivilai, P. Prasongdee, Total phenolic contents, total flavonoids and antioxidant activity of Thai basil (Ocimum basilicum L.), 5th Int. Conf. Nat. Prod. Health Beauty, Thailand, (2014).

H. Abramovic, V. Abram, A. Cuk, B. Ceh, S. Smole-Mozina, M. Vidmar, M. Pavlovic, N.P. Ulrih, Turk. J. Agric. For. 42 (2018) 185—194. https://doi.org/10.3906/tar-1711-82.

E.M. Kwee, E.D. Niemeyer, Food Chem. 128 (2011) 1044—1050. https://doi.org/10.1016/j.foodchem.2011.04.011.

U. Nazir, S. Javaid, H. Awais, F. Bashir, M. Shahid, Pure Appl. Biol. 10 (2021) 1004—1013. http://dx.doi.org/10.19045/bspab.2021.100105.

A.N. Yousif, C.H. Scaman, T.D. Durance, B. Girard, J. Agric. Food Chem. 47 (1999) 4777—4781. https://doi.org/10.1021/jf990484m.

D. Argyropoulos, J. Müller, Ind. Crops Prod. 52 (2014) 118—124. https://doi.org/10.1016/j.indcrop.2013.10.020.

M. Dorouzi, H. Mortezapour, H.-R. Akhavan, A.G. Moghaddam, Solar Energy 162 (2018) 364—371. https://doi.org/10.1016/j.solener.2018.01.025.

M. Ahmadi, K.R. Gluesenkamp, S. Bigham, Energy Convers. Manage. 230 (2021) 113763. https://doi.org/10.1016/j.enconman.2020.113763.

U. Pal, M.K. Khan, S. Mohanty, Drying Technol. 26 (2008) 1584—1590. https://doi.org/10.1080/07373930802467144.

E. Mancuhan, S. Özen, P. Sayan, S.T. Sargut, Drying Technol. 34 (2016) 1535—1545. https://doi.org/10.1080/07373937.2015.1135340.

A. Tarafdar, N. Jothi, B.P. Kaur, J. Appl. Res. Med. Aromat. Med. Plants 24 (2021) 100306. https://doi.org/10.1016/j.jarmap.2021.100306.

N. Çetin, J. Food Process. Preserv. 46 (2022) e17011. https://doi.org/10.1111/jfpp.17011.

T. Baysal, N. Ozbalta, S. Gokbulut, B. Capar, O. Tastan, G. Gurlek, Therm. Sci. Technol. 35 (2015) 135—144.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Mehmet Kalender, Aykut Topdemir

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.