Primena metoda površine odgovora za optimizaciju procesa visoke konverzije slobodnih masnih kiselina korišćenjem (1R)-(-)-kamfor-10-sulfonske kiseline i gvožđe(III) sulfata Naučni rad

Glavni sadržaj članka

Apstrakt

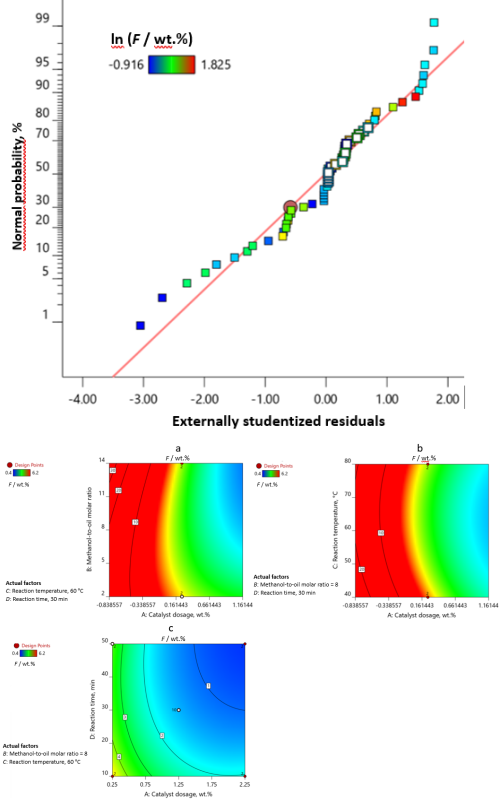

U radu je izvršeno ispitivanje proizvodnje biodizela iz kiselog sirovog palminog ulja korišćenjem jednog homogenog katalizatora, (1R)-(-)-kamfor-10-sulfonske kiseline (10-CSA) i jednog heterogenog katalizatora, gvožđe(III) sulfata, sa aspekta njihove katalitičke aktivnosti, mogućnosti recikliranja i optimizacije procesa primenom metode odgovora površine. Optimalni uslovi su identifikovani korišćenjem Bok-Behnken faktorskog dizajna. Za 10-CSA, optimizovani uslovi su dali smanjenje slobodnih masnih kiselina (FFA) na 0,43 mas.%, sa dozom katalizatora od 1,5 mas.% (ispitani opseg: 1,0-2,0 mas.%), molarnim odnosom metanola i ulja od 12,60 g do 1:1:1 (umereno temperaturno područje), temperaturom od 59,6 °C (ispitani opseg: 50 do 65 °C), i vremenom reakcije od 33,1 min (ispitani opseg: 30 do 40 min). Za gvožđe(III) sulfat, optimizovani uslovi su doveli do smanjenja FFA na 1,04 mas.%, sa dozom katalizatora od 3,14 mas.% (ispitani opseg: 2,5 do 3,5 mas.%), molarnim odnosom metanola i ulja od 12:1 (ispitani opseg temperature od 1:10°C), temperaturom reakcije od 60 °C (ispitani opseg: 55 do 70 °C), i vreme reakcije od 178,6 min (ispitani opseg: 150 do 180 min). Rezultati ANOVA analize su potvrdili značaj ključnih faktora za oba katalizatora (p <0,05), sa vrednostima R² od 0,937 za 10-CSA i 0,916 za gvožđe(III) sulfat, što ukazuje na dobro uklapanje modela. Srednja relativna procentna devijacija bila je <5 % za oba modela, što pokazuje visoku tačnost predviđanja. Utvrđeno je da je nedostatak uklapanja beznačajan (p >0,05), što potvrđuje adekvatnost modela. Oba katalizatora su postigla visoku konverziju FFA od 95,2 % za 10-CSA i 88,2 % za gvožđe(III) sulfat, što ispunjava standarde EN 14214 i ASTM D6751. Značajno je da je 10-CSA pokazao bolju katalitičku aktivnost i mogućnost recikliranja, čime se ističe njegov potencijal za proizvodnju biodizela u industrijskim razmerama. Ova studija nudi praktičan uvid u optimizaciju procesa esterifikacije za proizvodnju biodizela iz kiselog sirovog palminog ulja.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Autorstvo 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

King Saud University

Grant numbers (RSP2025R511

Reference

[1] Sani YM, Daud WMAW, Abdul Aziz AR. Solid acid-catalyzed biodiesel production from microalgal oil - The dual advantage. J Environ Chem Eng. 2013; 1(3): 113-121. https://doi.org/10.1016/j.jece.2013.04.006

[2] Akpan IO, Edeh I, Uyigue L. A Review on Biodiesel Production. Petrol Chem Ind Int. 2023; 6(2): 131-141. https://doi.org/10.33140/PCII.

[3] Sakthivel R, Ramesh K, Purnachandran R, Mohamed Shameer P. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew Sustain Energy Rev. 2018; 82: 2970-2992. https://doi.org/https://doi.org/10.1016/j.rser.2017.10.037

[4] Elgharbawy AS, Sadik WA, Sadek OM, Kasaby MA. Maximizing biodiesel production from high free fatty acids feedstocks through glycerolysis treatment. Biomass Bioenergy. 2021; 146: 105997. https://doi.org/10.1016/j.biombioe.2021.105997

[5] Wu Z, Cai J, Liu Z, Liang X, Yu S, Nie Y. Utilization of biodiesel and glycerol for the synthesis of epoxidized acyl glycerides and its application as a plasticizer. J Am Oil Chem Soc. 2023; 100: 733-741. https://doi.org/10.1002/aocs.12715

[6] Hayyan A, Mjalli FS, Hashim MA, Hayyan M, AlNashef IM, Al-Zahrani SM, Al-Saadi MA. Ethanesulfonic acid-based esterification of industrial acidic crude palm oil for biodiesel production. Bioresour Technol. 2011; 102(20): 9564-9570. https://doi.org/10.1016/j.biortech.2011.07.074

[7] Hayyan A, Hashim MA, Hayyan M. Agro-industrial acidic oil as a renewable feedstock for biodiesel production using (1R)-(-)-camphor-10-sulfonic acid. Chem Eng Sci. 2013; 16(6): 223-227. https://doi.org/10.1016/j.ces.2014.03.031

[8] Sun J, Zhu W, Mu B, Zhong J, Lin N, Chen S, Li Z. Efficient extraction of biodiesel feedstock and dehydration of kitchen waste: A method based on co-dissolution of liquefied dimethyl ether and water. Waste Manag. 2022; 147(1): 22-29. https://doi.org/10.1016/j.wasman.2022.04.044

[9] Singh B, Srivastava AK, Prakash O. A Comprehensive Review on Rare Biodiesel Feedstock Availability, Fatty Acid Composition, Physical Properties, Production, Engine Performance and Emission. Process Integr Optim Sustain. 2023; 7: 1081-1116. https://doi.org/10.1007/s41660-023-00343-w

[10] Hayyan A, Yeow ATH, Abed KM, Jeffrey Basirun W, Boon Kiat L, Saleh J, Wen Han G, Chia Min P, Aljohani ASM, Zulkifli MY, Alajmi FDH, Alhumaydhi FA, Kadmouse Aldeehani A, Ali Hashim M. The development of new homogenous and heterogeneous catalytic processes for the treatment of low grade palm oil. J Mol Liq. 2021; 344:117574. https://doi.org/10.1016/j.molliq.2021.117574

[11] Mateos PS, Casella ML, Briand LE, Matkovic SR. Transesterification of waste cooking oil with a commercial liquid biocatalyst: Key information revised and new insights. J. Am. Oil Chem. Soc. 2023; 100(4): 287-301. https://doi.org/10.1002/aocs.12683

[12] Ahmed R, Huddersman K. Review of biodiesel production by the esterification of wastewater containing fats oils and grease (FOGs). J Ind Eng Chem. 2022; 110: 1-14. https://doi.org/10.1016/j.jiec.2022.02.045

[13] Rattanaphra D, Harvey AP, Thanapimmetha A, Srinophakun P. Kinetic of myristic acid esterification with methanol in the presence of triglycerides over sulfated zirconia. Renew Energy. 2011; 36(10): 2679-2686. https://doi.org/10.1016/j.renene.2011.02.018

[14] Atadashi IM, Aroua MK, Abdul Aziz AR, Sulaiman NMN. The effects of catalysts in biodiesel production. J Ind Eng Chem. 2013; 19(1): 14-26. https://doi.org/10.1016/j.jiec.2012.07.009

[15] Lam MK, Lee KT, Mohamed AR. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel. Biotechnol Adv. 2010; 28(4): 500-518. https://doi.org/10.1016/j.biotechadv.2010.03.002

[16] Abdulmalek SA, Yan Y. Recent developments of lipase immobilization technology and application of immobilized lipase mixtures for biodiesel production. Biofuels Bioprod Bioref. 2022; 16(4): 1062-109. https://doi.org/10.1002/bbb.2349

[17] Jamil F, Saleem M, Ali Qamar O, Khurram MS, Al-Muhtaseb AH, Inayat A, Akhter P, Hussain M, Rafiq S, Yim H, Park YK. State-of-the-art catalysts for clean fuel (methyl esters) production—a comprehensive review. J Phys Energy. 2023; 5(1): 014005. https://doi.org/10.1088/2515-7655/aca5b3

[18] Bölük S, Sönmez Ö. Microwave‐Assisted Esterification of Oleic Acid Using an Ionic Liquid Catalyst. Chem Eng Technol. 2020; 43(9): 1792-1801. https://doi.org/10.1002/ceat.202000045

[19] Hayyan A, Hashim MA, Hayyan M. Application of a Novel Catalyst in the Esterification of Mixed Industrial Palm Oil for Biodiesel Production. Bioenergy Res. 2015; 8(1): 459-463. https://doi.org/10.1007/s12155-014-9502-0

[20] Winfield DD, Moser BR. Selective hydroxyalkoxylation of epoxidized methyl oleate by an amphiphilic ionic liquid catalyst. J Am Oil Chem Soc. 2022; 100(3): 237-243 https://doi.org/10.1002/aocs.12672

[21] Hayyan A, Yeow ATH, Alkahli NAM, Saleh J, Aldeehani AK, Alkandari KH, Alajmi FD, Alias Y, Junaidi MUM, Hashim MA, Basirun WJ, Abdelrahman MAA. Application of acidic ionic liquids for the treatment of acidic low grade palm oil for biodiesel production. J Ionic Liq. 2022; 2(1): 100023. https://doi.org/10.1016/j.jil.2022.100023

[22] Hayyan A, Ali Hashim M, Mjalli FS, Hayyan M, AlNashef IM. A novel phosphonium-based deep eutectic catalyst for biodiesel production from industrial low grade crude palm oil. Chem Eng Sci. 2013; 92: 81-88. https://doi.org/10.1016/j.ces.2012.12.024

[23] Hayyan A, Hizaddin HF, Abed KM, Mjalli FS, Hashim MA, Abo-Hamad A, Saleh J, Aljohani ASM, Alharbi YM, Alhumaydhi FA, Ahmad AA, Yeow ATH, Aldeehani AK, Alajmi FDH, Al Nashef I. Encapsulated deep eutectic solvent for esterification of free fatty acid. Biomass Convers Biorefin. 2022; 12(9): 3725-3735. https://doi.org/10.1007/s13399-021-01913-z

[24] Pelit E. Synthesis of isoxazolopyridines and spirooxindoles under ultrasonic irradiation and evaluation of their antioxidant activity. J Chem. 2017; 2017(1).9161505. https://doi.org/10.1155/2017/9161505

[25] Zhai Y, Pan K, Zhang E. Anti-Corrosive Coating of Carbon-Steel Assisted by Polymer-Camphorsulfonic Acid Embedded Within Graphene. Coatings. 2020; 10(9): 897. https://doi.org/10.3390/coatings10090879

[26] Guo P. Three 2D AgI-framework Isomers With Helical Structures Controlled by the Chirality of Camphor-10-Sulfonic Acid. Daltan Transanction. 2011: 1716. https://doi.org/10.1039/C0DT01384F

[27] Krupińska I. The influence of aeration and type of coagulant on effectiveness in removing pollutants from groundwater in the process of coagulation. Chem Biochem Eng Q. 2016; 30(4): 465-475. https://doi.org/10.15255/CABEQ.2014.2016

[28] GY Han, GQ Shi, LT Qu, JY Yuan, FE Chen PW. Electrochemical Polymerization of Chiral Pyrrole Derivatives in Electrolytes Containing Chiral Camphor Sulfonic Acid. Polymer International. 2004: 53 (10): 1554-1560. https://doi.org/10.1002/pi.1597

[29] Garcia FJ, Rubio A, Sainz E, Gonzalez P, Lopez FA. Preliminary study of treatment of sulphuric pickling water waste from steelmaking by bio-oxidation with Thiobacillus ferrooxidans. FEMS Microbiol Rev. 1994; 14(4): 397-404. https://doi.org/10.1111/j.1574-6976.1994.tb00114.x

[30] American Oil Chemist’s Society. Ca 5a-40: free fatty acids, in: Official Methods and Recommended Practices of the AOCS. 5th ed. Champaign, IL; 1998. ISBN: 978-0-935315-82-8.

[31] Park SH, Khan N, Lee S, Zimmermann K, DeRosa M, Hamilton L, Hudson W, Hyder S, Serratos M, Sheffield E. Biodiesel production from locally sourced restaurant waste cooking oil and grease: synthesis, characterization, and performance evaluation. ACS Omega. 2019; 4(4): 7775-7784. https://doi.org/10.1021/acsomega.9b00268

[32] Ude CN, Onukwuli OD, Ugwu BI, Okey-Onyesolu CF, Ezidinma TA, Ejikeme PM. Methanolysis optimization of cottonseed oil to biodiesel using heterogeneous catalysts. Iran. J Chem Chem Eng. 2020; 39(4): 355-370. https://doi.org/10.30492/ijcce.2020.43368

[33] Borugadda VB, Goud V V. Response surface methodology for optimization of bio-lubricant basestock synthesis from high free fatty acids castor oil. Energy Sci Eng. 2015; 3(4): 371-83. https://doi.org/10.1002/ese3.77

[34] Evans R. Verifying Model Assumptions and Testing Normality. Vet. Surg. 2024; 53(1). 17. https://doi.org/10.1111/vsu.14034

[35] Jia P, Lan X, Li X, Wang T. Highly Active and Selective NiFe/SiO2 Bimetallic Catalyst with Optimized Solvent Effect for the Liquid-Phase Hydrogenation of Furfural to Furfuryl Alcohol. ACS Sustain Chem Eng. 2018; 6(10): 13287-13295. https://doi.org/10.1021/acssuschemeng.8b02876

[36] Xie W, Gao C, Wang H. Biodiesel production from low-quality oils using heterogeneous cesium salts of vanadium-substituted polyoxometalate acid catalyst. Catalysts. 2020; 10(9): 1060. 1-13. https://doi.org/10.3390/catal10091060

[37] Faruque MO, Razzak SA, Hossain MM. Application of heterogeneous catalysts for biodiesel production from microalgal oil—a review. Catalysts. 2020; 10(9): 1025. https://doi.org/10.3390/catal10091025

[38] Ma’arof NANB, Hindryawati N, Khazaai SNM, Bhuyar P, Rahim MHAb, Maniam GP. Biodiesel (Methyl Esters). Maejo Int. J. Energy Environ Commun. 2021; 3(1): 30-43. https://doi.org/10.54279/mijeec.v3i1.245153

[39] Xie W, Wang H. Immobilized polymeric sulfonated ionic liquid on core-shell structured Fe3O4/SiO2 composites: A magnetically recyclable catalyst for simultaneous transesterification and esterifications of low-cost oils to biodiesel. Renew Energy. 2020; 145: 1709-1719. https://doi.org/10.1016/j.renene.2019.07.092

[40] Díaz L, Borges ME. Low-quality vegetable oils as feedstock for biodiesel production using k-pumice as solid catalyst. Tolerance of water and free fatty acids contents. J Agric Food Chem. 2012; 60(32): 7928-3793. https://doi.org/10.1021/jf301886d

[41] Khor CP, Jaafar M bt, Ramakrishnan S. Optimization of Conductive Thin Film Epoxy Composites Properties Using Desirability Optimization Methodology. J Optim. 2016: 652928. 1652928. https://doi.org/10.1155/2016/1652928

[42] Loryuenyong V, Kaewmanee S, Rattanawaraporn S, Chimplenapanon N, Buasri A. Optimization of microwave-assisted biodiesel production using Iron (III) oxide - Calcium oxide / Activated charcoal derived from waste Asian green mussel shell as heterogeneous catalyst. IOP Conf Ser Mater Sci Eng. 2023; 1280(1): 012004. https://doi.org/10.1088/1757-899x/1280/1/012004

[43] Melchiorre M, Amoresano A, Budzelaar PHM, Cucciolito ME, Mocerino F, Pinto G, Ruffo F, Tuzi A, Esposito R. Parts-Per-Million (Salen)Fe(III) Homogeneous Catalysts for the Production of Biodiesel from Waste Cooking Oils. Catal Letters. 2022; 152(12): 3785-3794. https://doi.org/10.1007/s10562-022-03948-x

[44] Betiku E, Etim AO, Pereao O, Ojumu TV. Two-Step Conversion of Neem (Azadirachta indica) Seed Oil into Fatty Methyl Esters Using a Heterogeneous Biomass-Based Catalyst: An Example of Cocoa Pod Husk. Energy Fuels. 2017; 31(6): 6182-6193. https://doi.org/10.1021/acs.energyfuels.7b00604

[45] Chai M, Tu Q, Lu M, Yang YJ. Esterification pretreatment of free fatty acid in biodiesel production, from laboratory to industry. Fuel Process. Technol. 2014; 125: 106-113. https://doi.org/10.1016/j.fuproc.2014.03.025

[46] Okpalaeke KE, Ibrahim TH, Latinwo LM, Betiku E. Mathematical Modeling and Optimization Studies by Artificial Neural Network, Genetic Algorithm and Response Surface Methodology: A Case of Ferric Sulfate-Catalyzed Esterification of Neem (Azadirachta indica) Seed Oil. Front Energy Res. 2020; 8(November): 1-14. https://doi.org/10.3389/fenrg.2020.614621

[47] Anil N, Rao PK, Sarkar A, Kubavat J, Vadivel S, Manwar NR, Paul B. Advancements in sustainable biodiesel production: A comprehensive review of bio-waste derived catalysts. Energy Convers Manag. 2024; 318: 118884. https://doi.org/https://doi.org/10.1016/j.enconman.2024.118884

[48] Pasha MK, Dai L, Liu D, Guo M, Du W. An overview to process design, simulation and sustainability evaluation of biodiesel production. Biotechnol Biofuels. 2021; 14(1): 1-24. https://doi.org/10.1186/s13068-021-01977-z

[49] Kokanović A, Ajdačić V, Terzić Jovanović N, Stankic S, Opsenica IM. Pd Nanoparticles Supported on Ultrapure ZnO Nanopowders as Reusable Multipurpose Catalysts. ACS Appl Nano Mater. 2023; 6(17): 15820-15828. https://doi.org/10.1021/acsanm.3c02743

[50] Rathore D, Sevda S, Prasad S, Venkatramanan V, Chandel AK, Kataki R, Bhadra S, Channashettar V, Bora N, Singh A. Bioengineering to Accelerate Biodiesel Production for a Sustainable Biorefinery. Bioeng. 2022; 9(11): 618. 1ttps://doi.org/10.3390/bioengineering9110618

[51] Alhomaidi E, Aljabri M, Alsharari SS, Alsam A. Chromatographic assessment of biodiesel production from Peganum harmala seed oil using environmentally benign nano-catalysts. Biomed Chromatogr. 2024; 38(3): e5794. https://doi.org/10.1002/bmc.5794

[52] Oloyede CT, Jekayinfa SO, Alade AO, Ogunkunle O, Otung NAU, Laseinde OT. Exploration of agricultural residue ash as a solid green heterogeneous base catalyst for biodiesel production. Eng Rep. 2023; 5(1): 1-23. https://doi.org/10.1002/eng2.12585