Eksperimentalna analiza atmosferske korozije čelika S235JR u industrijskoj sredini Naučni rad

Glavni sadržaj članka

Apstrakt

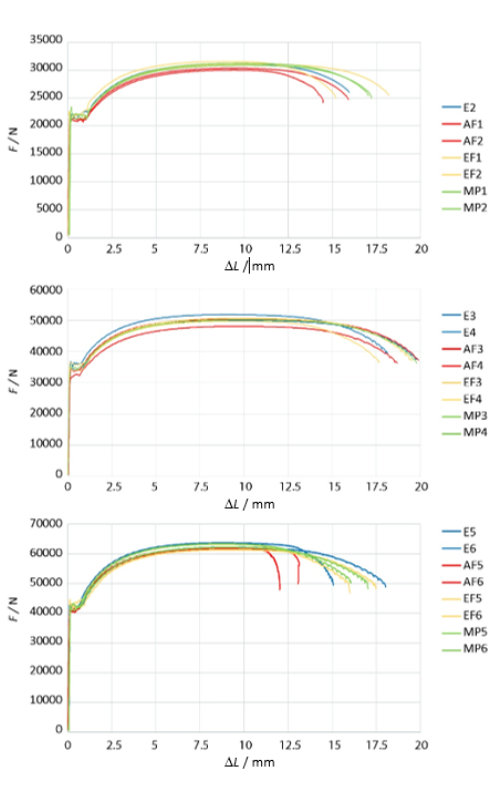

U ovom radu ispitana je atmosferska korozija konstrukcionog čelika S235JR u industrijskoj sredini. Opšta ispitivanja korozije vršena su u blizini fabrike sumporne kiseline, u postrojenju za elektrolitičku rafinaciju i pored automatske stanice za praćenje kvaliteta vazduha u Boru u periodu od 6 meseci. Za ispitivanje međusobnog dejstva korozije i zagađenja industrijske sredine, korišćen je čelik S235JR, a njegove mehaničke karakteristike su dobijene ispitivanjem zatezanjem. Određeni su i meteorološki parametri, kao i zagađujuće materije u atmosferi (uglavnom SO2). Rendgenska difrakciona analiza (engl. X-ray diffraction, XRD) je korišćena za identifikaciju minerološkog sastava produkata korozije. XRD analiza može ukazati na vezu između gubitka nosivosti i vrste sredine u kojoj se korozija razvija. Na osnovu dobijenih rezultata vrši se dalje predviđanje degradacije materijala usled korozije u industrijski agresivnoj sredini. Istraživanja u okviru ovog rada su omogućila bolje razumevanje ponašanja konstrukcionog čelika S235JR u kom je došlo do redukcije nosivosti usled korozije. Utvrđeno je da su produkti korozije različita jedinjenja u zavisnosti od sadržaja zagađujućih materija u atmosferi i lokacije čeličnih elemenata.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Autorstvo 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-66/2024-03/200052;200092;451-03-66/2024-03/200287

Reference

[1] Mendoza A, Corvo F. Outdoor and indoor atmospheric corrosion of carbon steel. Corros Sci. 1999; 41: 75-86. https://doi.org/10.1016/S0010-938X(98)00081-X

[2] Gil H, Calderón J. A, Buitrago C. P, Echavarría A, Echeverría F. Indoor atmospheric corrosion of electronic materials in tropical-mountain environments. Corros Sci. 2010; 52(2): 327-337. https://doi.org/10.1016/j.corsci.2009.09.019

[3] Del Angel-Meraz E, Corvo F, Hernandez-Morales N, Tejero-Rivas M. Particularities of indoor atmospheric corrosion of steel inside electric boxes in the tropical climate of Tabasco, Mexico. Indoor Built Environ. 2020; 30(10): 1609-1619. https://doi.org/10.1177/1420326X20950411

[4] Rajaković-Ognjanović V, Grgur B. Corroded scale analysis from water distribution pipes. Hem. Ind. 2011; 65(5): 507-515. https://doi.org/10.2298/HEMIND110523049R

[5] Xue X, Hua J, Wang F, Wang N, Li S. Mechanical Property Model of Q620 High-Strength Steel with Corrosion Effects. Buildings. 2022; 12: 1651. https://doi.org/10.3390/buildings12101651

[6] Zhao N, Zhang C. Experimental Investigation of the Mechanical Behavior of Corroded Q345 and Q420 Structural Steels. Buildings. 2023; 13: 475. https://doi.org/10.3390/buildings13020475

[7] Di Sarno L, Majidian A, Karagiannakis G. The Effect of Atmospheric Corrosion on Steel Structures: A State-of-the-Art and Case-Study. Buildings. 2021; 11: 571. https://doi.org/10.3390/buildings11120571

[8] Li F, Cui C, Ma R, Tian H. An experimental study on the corrosion behaviors and mechanical properties of Q345qD steel in neutral salt spray environment considering stress state. Dev Built Environ. 2023; 15: 100214. https://doi.org/10.1016/j.dibe.2023.100214

[9] Stefanović J, Dimitrijević S, Filipović S, Đorđević J. Evaluation of the corrosion resistance of steel elements in the industrially aggressive environments using the accelerated corrosion testing methods. Min Metall Eng Bor. 2023; 1: 53-60. https://doi.org/10.5937/mmeb2104053S

[10] Sanders C, Santucci R. Jr. Experimental Design Considerations for Assessing Atmospheric Corrosion in a Marine Environment: Surrogate C1010 Steel. Corros Mater Degrad. 2023; 4(1): 1-17. https://doi.org/10.3390/cmd4010001

[11] Parekh SP, Pandya AV, Kadiya HK. Progressive Atmospheric Corrosion Study of Metals Like Mild Steel, Zinc and Aluminum in Urban Station of Ahmedabad District. Int J Chemtech Res. 2012; 4: 1700-1774. http://dx.doi.org/10.1155/2009/807376

[12] ISO Standard 8407:2021 Corrosion of Metals and Alloys: Corrosivity of atmospheres: Removal of Corrosion Products from Corrosion Test Specimens. https://www.iso.org/standard/71866.html

[13] PDXL, Version 2.0. 3.0 Integrated X-ray Powder Diffraction Software, Rigaku Corporation. Tokyo, Japan; https://rigaku-pdxl.software.informer.com/2.0/

[14] Аnnual and monthly reports on ambient air quality in Bor for the period 2016-2017 (Archive MMI Bor), Mining and Metallurgy Institute Bor (MMI Bor), Laboratory for Chemical Testing, Department for Environmental Protection and Climate Change, Bor, Serbia.

[15] Annual report on air quality in the Republic of Serbia in 2016, Republic of Serbia, Ministry of Environmental Protection, Environmental protection agency, Belgrade, Serbia. https://sepa.gov.rs/wp-content/uploads/2024/10/Vazduh2016.pdf. Accessed 2017.

[16] Annual report on air quality in the Republic of Serbia in 2017, Republic of Serbia, Ministry of Environmental Protection, Environmental protection agency, Belgrade, Serbia. https://sepa.gov.rs/wp-content/uploads/2024/10/Vazduh2017.pdf Accessed 2018.

[17] Seechurn Y, Surnam B, Wharton J. Marine atmospheric corrosion of carbon steel in the tropical microclimate of Port Louis. Mater Cor. 2022; 73: 1474-1489. https://doi.org/10.1002/maco.202112871

[18] Pan C, Han W, Wang Z, Wang C, Yu G. Evolution of Initial Atmospheric Corrosion of Carbon Steel in an Industrial Atmosphere. JMEP. 2016; 25: 5382-5390. https://doi.org/10.1007/s11665-016-2312-0

[19] Wu H, Luo Y, Zhou G. The Evolution of the Corrosion Mechanism of Structural Steel Exposed to the Urban Industrial Atmosphere for Seven Years. Appl Sci. 2023; 13: 4500. https://doi.org/10.3390/app13074500

[20] Qin H, Liu J, Shao Q, Zhang X, Teng Y, Chen S, Zhang D, Bao S. Corrosion behavior and cellular automata simulation of carbon steel in salt-spray environment. Mater Degrad. 2024; 8: 29. https://doi.org/10.1038/s41529-024-00447-9

[21] De la Fuente D, Díaz I, Simancas J, Chico B, Morcillo M. Long-term atmospheric corrosion of mild steel. Cor Sci. 2011; 53: 604-617. https://doi.org/10.1016/j.corsci.2010.10.007

[22] Dhaiveegan P, Elangovan N, Nishimura T, Rajendran N. Weathering Steel in Industrial-Marine-Urban Environment: Field Study. MaterTrans. 2016; 57, (2): 148-155. https://doi.org/10.2320/matertrans.M2015345

[23] ISO Standard 9223:2012 Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation. https://www.iso.org/standard/53499.html

[24] ISO Standard 9226:2012 Corrosion of metals and alloys—Corrosivity of atmospheres—Determination of corrosion rate of standard specimens for the evaluation of corrosivity. https://www.iso.org/standard/53502.html

[25] Montoya P, Díaz I, Granizo N, de la Fuente D, Morcillo M. An study on accelerated corrosion testing of weathering steel. Mater. Chem. Phys. 2013; 142: 220-228. https://doi.org/10.1016/j.matchemphys.2013.07.009

[26] Zhang Z, Xu Y, Qin G, Xu S, Li R. Deterioration of Mechanical Properties and the Damage Constitutive Model of Corroded Steel in an Industrial Environment. Materials. 2022; 15: 8841. https://doi.org/10.3390/ma15248841