Predviđanje funkcionalnih karakteristika interlok i rebrastih pletiva korišćenjem 3D računarskog modelovanja i analize Naučni rad

Glavni sadržaj članka

Apstrakt

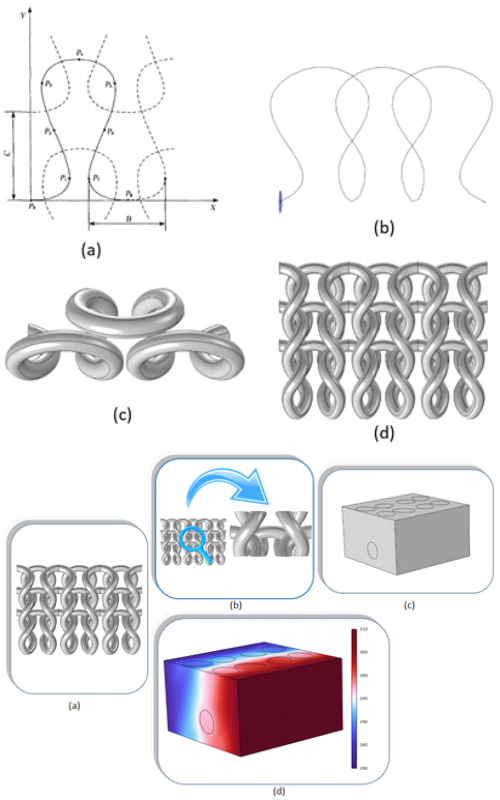

U ovom radu je razvijen računarski model interlok i rebrastih pletiva kako bi se predvideli propustljivost vazduha i termička svojstva tkanine. Ponavljajuće jedinične ćelije interlok i rebrastih pletenih struktura razvijene su u COMSOL Multiphysics® softveru, korišćenjem stvarnih parametara tkanine ekstrahovanih uz pomoć tehnike analize slike. Dobijeni rezultati modelovanja s zatim upoređena sa stvarnim eksperimentalnim vrednostima za tkaninu. Pored toga, validirani računarski model je korišćen za analizu uticaja dužine boda i debljine tkanine na termička svojstva i vazdušnu propustljivost tkanine. Utvrđeno je da dužina boda direktno proporcionalna vazdušnoj propustljivosti i obrnuto proporcionalna efektivnoj toplotnoj provodljivosti tkanine. Debljina tkanine direktno utiče na efektivnu toplotnu provodljivost, a obrnuto proporcionalno na vazdušnu propustljivost tkanine.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Autorstvo 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Higher Education Commision, Pakistan

Grant numbers GCF-63 WP#04

Reference

[1] Li YL, Chen SY, Yang LH, Cao LH. Study on three-dimension computer simulation of plain knitted fabrics. Adv Mat Res. 2011; 213: 595–599 https://doi.org/10.4028/www.scientific.net/AMR.213.595

[2] Sha S, Geng A, Gao Y, Li B, Jiang X, Tao H, Luo L, Yuan X, Ke H, Hu X. Review on the 3D simulation for weft knitted fabric. J Eng Fiber Fabr. 2021; 16: 1-10 https://doi.org/10.1177/15589250211012527

[3] Peirce FT. Geometrical principles applicable to the design of functional fabrics. Text Res J. 1947; 17(3): 123-147. https://doi.org/10.1177/004051754701700301

[4] Hurd JCH, Doyle, PJ. Fundamental aspects of the design of knitted fabrics. J Text Inst Proc. 1953; 44(8): 561-578. https://doi.org/10.1080/19447015308687861

[5] Shinn WE. An engineering approach to jersey fabric construction. Text Res J. 1953; 25(3): 270-277. https://doi.org/10.1177/004051755502500314

[6] Leaf GAV, Glaskin A. 43—The geometry of a plain knitted loop. J Text Inst Trans. 1955; 46(9): T587-T605. https://doi.org/10.1080/19447027.1955.10750345

[7] Munden D L. 26—The geometry and dimensional properties of plain-knit fabrics. J Text Inst Trans. 1959; 50(7): T448-T471. https://doi.org/10.1080/19447025908659923

[8] Postle R. 6—Dimensional stability of plain-knitted fabrics. J Text Inst. 1968; 59(2): 65-77. https://doi.org/10.1080/00405006808659967

[9] Kurbak A. Plain knitted fabric dimensions (Part II). Text A. 1998; 78: 36-44.

[10] Demiroz A, Dias T. A study of the graphical representation of plain-knitted structures part I: Stitch model for the graphical representation of plain-knitted structures. J Text Inst. 2000; 91(4): 463-480. https://doi.org/10.1080/00405000008659121

[11] Choi KF, Lo TY, An energy model of plain knitted fabric. Text Res J. 2003; 73(8): 739-748. https://doi.org/10.1177/004051750307300813

[12] Kyosev Y, Angelova Y and Kovar R. 3D modeling of plain weft knitted structures of compressible yarn. Res J Text Appar. 2005; 9(1): 88-97. https://doi.org/10.1108/RJTA-09-01-2005-B009

[13] Delavari K, Dabiryan H. Mathematical and numerical simulation of geometry and mechanical behavior of sandwich composites reinforced with 1× 1-Rib-Gaiting weft-knitted spacer fabric; compressional behavior. Compos Struct. 2021; 268: 113952. https://doi.org/10.1016/j.compstruct.2021.113952

[14] Ghatrenabi MH, Dabiryan H, Nosraty H. Modeling the Geometry of Weft-knitted Integrated Preforms as Reinforcement of Composite Joints. Fibers Polym. 2021; 22(9): 2572-2580. https://doi.org/10.1007/s12221-021-1180-x

[15] Omrani E, Dibajian SH, Hasani H. Development of ABAQUS Plugin Predicting the Mechanical Behavior and Failure Modes of Weft knitted-Reinforced Composites. Fibers Polym. 2025; 26: 883-907. http://dx.doi.org/10.1007/s12221-025-00850-2

[16] Huang R. Characterization and Modeling of Pores in Weft-Knitted Fabrics. PhD Dissertation, North Carolina State University; 2023. https://www.lib.ncsu.edu/resolver/1840.20/40816

[17] Ogulata RT. Air permeability of woven fabrics. J Text Appar Tech and Manag. 2006; 5(2): 1–10. https://www.researchgate.net/publication/283451342_Air_Permeability_of_Woven_Fabrics

[18] Jeddi AAA, Dabiryan H. Ideal stitch model for interlock-knitted fabric. J Text Inst. 2008; 99(4): 369–374. https://doi.org/10.1080/00405000701584444

[19] Li Y L, Yang L H, Chen S Y, Yuan J, Li N-N. 3D modeling and simulation of fancy fabrics in weft knitting. J DongHua Uni. 2012; 29(4): 351-358. https://doi.org/10.19884/j.1672-5220.2012.04.013

[20] Kejkar VKV, Tjprc. An Effect of Stitch Length. Lycra Percentage on Comfort Properties of Knitted Sport Wear. Int J Text Fash Tech. 2019; 9(3): 1-10. https://paper.researchbib.com/view/paper/225864

[21] Chakroun M G, Benltoufa S, Fayala F. The effect of fabric’s structure on the breathability and the drying rate properties. Comm Develop Assem Text Prod. 2021; 2(1): 61–69. https://doi.org/10.25367/cdatp.2021.2.p61-69

[22] Megeid ZMA, Al-Bakry M, Ezzat M. The influence of stitch length of weft knitted fabrics on the sewability. J Amer Sci. 2011; 7(8): 610–617. https://www.jofamericanscience.org/journals/am-sci/am0708/068_6200am0708_610_617.pdf

[23] Gebart BR. Permeability of unidirectional reinforcements for RTM. J Compos Mater 1992; 26(8): 1100–1133. https://doi.org/10.1177/002199839202600802

[24] Afzal A, Ahmad S, Rasheed A, Ahmad F, Iftikhar F, Nawab Y. Influence of fabric parameters on thermal comfort performance of double layer knitted interlock fabrics. Autex Res J. 2017; 17(1): 20–26. https://doi.org/10.1515/aut-2015-0037

[25] Kaviany M. Principles of Heat Transfer in Porous Media. 2nd ed., Springer, New York, USA; 1995. https://doi.org/10.1016/S0017-9310(05)80083-3