Thermal conductivity analysis of Al2O3/water-ethylene glycol nanofluid by using factorial design of experiments in a natural convection heat transfer apparatus Original scientific paper

Main Article Content

Abstract

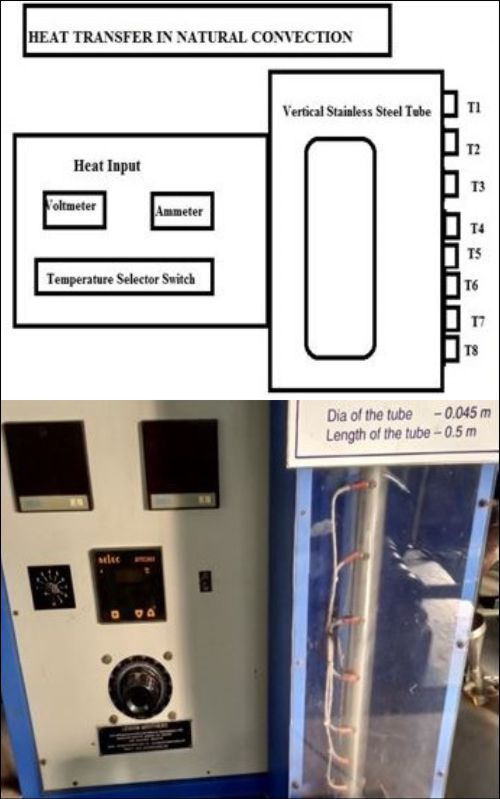

Thermal conductivity of a heat transfer fluid plays a significant role in improving the heat transfer performance of a heat exchanger. In this work, experiments were performed in a natural convection heat transfer apparatus by mixing homogenized Al2O3 nanoparticles in a base fluid of water-ethylene glycol mixtures. The effects of heat input, nanoparticle volume content in the base fluid, and ethylene-glycol volume content in the base fluid on thermal conductivity of the nanofluid were analyzed. Based on results obtained by MINITAB® design software (factorial design matrix), 16 experimental runs were performed with the lower and higher levels of input factors. The levels for heat input were 10 and 100 W; for nanoparticle volume content in the base fluid 0.1 and 1 vol.% and for the base fluid composition 30 and 50 vol.% of ethylene glycol in water. From the obtained experimental results, a Pareto chart, normal probability plot, contour plot and surface plot were drawn. Based on the results, a new correlation was proposed, and predictions were compared with the experimental results. From the study, the maximum thermal conductivity value 0.49 W m-1 K-1 was observed at a nanoparticle volume content in the base fluid of 1.0 vol.%, ethylene glycol volume content in the base fluid of 30 vol.% and heat input of 100 W.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

Zlatković NR, Majstorović DM, Kijevčanin ML, Živković EM. Plate heat exchanger design software for industrial and educational applications. Hem. Ind.2017;71:439-449.https://doi.org/10.2298/HEMIND161021007Z

Choi SUS. Enhancing Thermal Conductivity of Fluids with Nanoparticles. In: D. A. Siginer and H. P. Wang, eds. Developments and Applications of Non-Newtonian Flows, FED-Vol. 231/MD-Vol. 66, ASME, New York, 1995, pp. 99–105.

Lee S, Choi SUS, Li S, Eastman JA. Measuring thermal conductivity of fluids containing oxide nanoparticles. J Heat Transfer. 1999;121:280-289. https://doi.org/10.1115/1.2825978

Wang X, Xu X, Choi SUS. Thermal Conductivity of Nanoparticle - Fluid Mixture. J Thermophys Heat Transfer. 1999;13:474–480. https://doi.org/10.2514/2.6486

Li CH, Peterson GP. The effect of particle size on the effective thermal conductivity of Al2O3 water nanofluid. J Appl Phys. 2007;101:044312. https://doi.org/10.1063/1.2436472

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transfer. 1998;11:151–170. https://doi.org/10.1080/08916159808946559

Anisha M, Kanimozhi B, Beemkumarb N, Jayaprapakar J. Experimental and numerical analysis of heat transfer from main vessel to safety vessel using H2O/Al2O3 nanofluid in a nuclear reactor vault. Desalin Water Treat. 2018;114:135-145. https://doi.org/10.5004/dwt.2018.22384

AbdEihafez SE, EI-Shazly AH, EI- Maghraby A. Improving the rate of solar from nanofluid using micro heat exchanger. Desalin Water Treat. 2016;57: 23066-23073. https://doi.org/10.1080/19443994.2016.1157987

Manikandan SP, Baskar R. Assessment of the Influence of Graphene Nanoparticles on Thermal Conductivity of Graphene/Water Nanofluid Using Factorial Design of Experiments. Period Polytech Chem Eng. 2018;62:317-322. https://doi.org/10.3311/PPch.11676

Manikandan SP, Baskar R. Experimental heat transfer studies on copper nanofluid in a plate heat exchanger. Chem Ind Chem Eng Q. 2021;27:15-20. https://doi.org/10.2298/CICEQ191220020P

Manikandan SP, Baskar R. Heat transfer studies in compact heat exchanger using ZnO and TiO2 Nanofluid in Ethylene Glycol/Water. Chem Ind Chem Eng Q. 2018;24:309-318. https://doi.org/10.2298/CICEQ170720003M

Manikandan SP, Baskar R. Studies on thermo physical property variations of graphene nanoparticle suspended ethylene glycol/water. Chem Ind Chem Eng Q. 2021;27:177-187. https://doi.org/10.2298/CICEQ200504036P

Huang D, Wu Z, Sunden B. Pressure drop and convective heat transfer of Al2O3/water and MWCNT/water nanofluid in a chevron plate heat exchanger. Int J Heat Mass Transfer. 2015;89:620–626. https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.082

Shanmugapriya M, Sangeetha P. Entropy generation analysis of Cu-water nanofluid flow over a moving wedge. Desalin Water Treat. 2018;121:14-21. https://doi.org/10.5004/dwt.2018.22189

Kim SH, Choi SR, Kim D. Thermal conductivity of metal-oxide nanofluids: Particle size dependence and effect of laser irradiation. J Heat Transfer. 2007:129:298-307. https://doi.org/10.1115/1.2427071

Kwon YH, Kim D, Li CG, Lee JK, Hong DS, Lee JG, Kim SH. Heat Transfer and Pressure Drop Characteristics of Nanofluid in a Plate Heat Exchanger. J Nanosci Nanotechnol. 2011;11:5769–5774. https://doi.org/10.1166/jnn.2011.4399

Patel HE, Sundararajan T, Das SK. An experimental investigation into the thermal conductivity enhancement in oxide and metallic nanofluids. J Nanopart Res. 2010; 12:1015–1031. https://doi.org/10.1007/s11051-009-9658-2

Wen D, Ding Y. Experimental investigation into convective heat transfer of nanofluid at the entrance region under laminar flow conditions. Int J Heat Mass Transfer. 2004;47: 5181–5188. https://doi.org/10.1016/j.ijheatmasstransfer.2004.07.012

Mohebbi R, Khalilabad SH, Ma Y. Effect of -Al2O3/Water nanofluid on natural convection heat transfer of corrugated shaped cavity: study the different aspect ratio of grooves. J Appl Fluid Mech. 2019;12:1151-1160. https://doi.org/10.29252/JAFM.12.04.29455

Satti JR, Das DK, Ray D. Investigation of the thermal conductivity of propylene glycol nanofluid and comparison with correlations. Int J Heat Mass Transfer. 2017:107: 871–881. https://doi.org/10.1016/j.ijheatmasstransfer.2016.10.121

Barbés B, Páramo R, Blanco E, Pastoriza-Gallego MJ, Piñeiro MM, Legido JL. Thermal conductivity and specific heat capacity measurements of Al2O3 nanofluids. J Therm Anal Calorim. 2013; 111:1615–1625. https://doi.org/10.1007/s10973-012-2534-9

Pandey SD, Nema VK. Experimental analysis of heat transfer and friction factor of nanofluidas a coolant in a corrugated plate heat exchanger. Exp Therm Fluid Sci.2012;38:248–256. https://doi.org/10.1016/j.expthermflusci.2011.12.013

Rashidi I, Mahian O, Lorenzini G, Biserni C, Wongwises S. Natural convection of Al2O3/water nanofluid in a square cavity: effects of heterogeneous heating. Int J Heat Mass Transfer. 2014;74: 391–402. https://doi.org/10.1016/j.ijheatmasstransfer.2014.03.030

Durga Prasad PV, Gupta S, Sreeramulu M, Sundar LS, Singh MK, Sousa ACM. Experimental study of heat transfer and friction factor of Al2O3 nanofluid in U-tube heat exchanger with helical tape inserts. Exp Therm Fluid Sci. 2015; 62:141–150. https://doi.org/10.1016/j.expthermflusci.2014.12.006

Arunkumar T, Kaiwalya Raja, Denkenberger D, Velraja R. Heat carrier nanofluid in solar still-A review. Desalin Water Treat. 2018; 130:1-16. https://doi.org/10.5004/dwt.2018.22972

Maiga SEB, Nguyen CT, Galanis N, Roy G. Heat transfer behaviours of nanofluid in a uniformly heated tube. Superlattices Microstruct. 2004; 35:543–557. https://doi.org/10.1016/j.spmi.2003.09.012

Nesakumar D, Baskar R. Analysis of TiO2-ZnO/EG Hybrid Nanofluid Effect on Heat Transfer Enhancement. Appl Math Inf Sci. 2019:13: 965-972. https://doi.org/10.18576/amis/130609

Lenth RV. Quick and easy analysis of unreplicated factorials. Technometrics. 1989;31:469-473. https://doi.org/10.2307/1269997

Plackett RL, Burman JP. The Design of Optimum Multifactorial Experiments. Biometrika. 1946;33:305-325. https://doi.org/10.2307/2332195