Ocena svojstava propustljivosti žakar tkanina dobijenih tehnološkim postupkom Naučni rad

Glavni sadržaj članka

Apstrakt

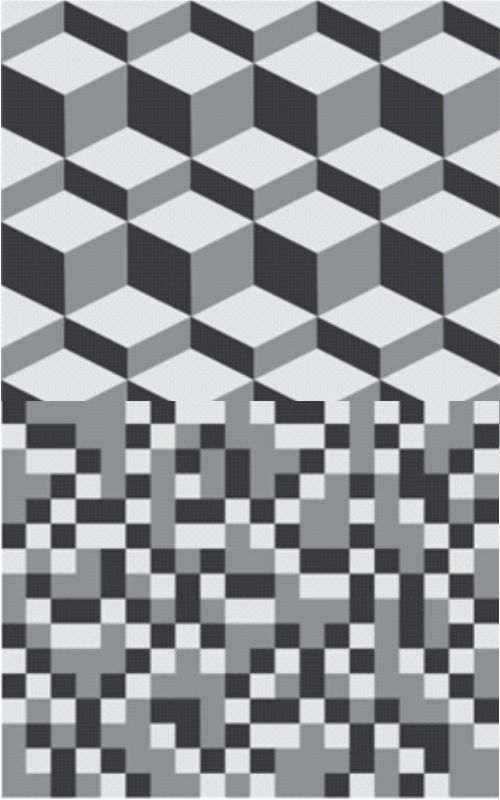

U okviru ovog istraživanja ispitivan je uticaj određenih parametara dizajna na svojstva propustljivosti žakar tkanina. Proizvedeno je šest tkanina od iste pamučne pređe za osnovu i sa istim tehnološkim parametrima razboja. Tkanine su izrađene od dve različite vrste pređa za potku (pamuk i Lyuocell Clima), u dve različite veličine dezena (sa većim i manjim monohromatskim površinama) i dve grupe dvostrukih keper prepletaja (dvoslojne tkanine spojene sopstvenim žicama, dvoslojne tkanine sa mestimičnom zamenom pozicije gornje i donje tkanine). Dokazan je značaj veličine i raspodele motiva, vrste prepletaja i vrste pređa korišćenih za izradu ispitivanih žakar tkanina. Takođe je ustanovljeno da je uticaj ovih parametara na svojstva propustljivosti u bliskoj vezi sa estetskim karakteristikama tkanina. Sve dvoslojne tkanine u prepletaju gde dolazi do mestimične zamene pozicije gornje i donje tkanine imaju značajno veću propustljivost vazduha u poređenju sa dvoslojnim tkaninama koje su spojene sopstvenim žicama. Očigledan je uticaj sirovinskog sastava i veličine motiva na toplotnu provodljivost žakar tkanina. Tkanine sa većim površinama motiva, gde je izraženije prisustvo potke, odlikuju se većom toplotnom provodljivošću. Sa druge strane, pokazalo se da, za razliku od sirovinskog sastava, veličina motiva ne utiče na ultraljubičasti zaštitni faktor (engl. ultraviolet protection factor, UPF) žakar tkanina.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Decrette M, Mourad S, Osselin JF, Drean JY. Jacquard UNIVAL 100 parameters study for high-density weaving optimization. J Ind Text. 2016; 45(6): 1603-1618. https://doi.org/10.1177/1528083714567241

Yavuzkasap AYakta D, Çaglar Cinperi N, Özdemir H. Investigating the effect of self-cleaning treatment on the air permeability, stain removal and water repellency properties of functionalized double jacquard woven upholstery fabrics. Ind Textila. 2019; 70 (6): 512-518. http://doi.org/10.35530/IT.070.06.1483 .

Akgün M, Ulu İ, Erkek E. The effect of properties and positioning of yarns used in jacquard woven fabric pattern on abrasion resistance. Tekst. 2021; 28 (123): 180-190. https://doi.org/10.7216/1300759920212812303 .

Süle G. The Effects of Jacquard Woven Fabric Constructional Parameters and Elastane Yarn on Bending Rigidity. J Eng Fibers Fabr. 2015; 10 (2): 164-170. https://doi.org/10.1177/155892501501000219 .

Kostajnšek K, Dimitrovski K, Kadoğlu H, Çelik P, Başal Bayraktar G, Bedez Üte T, Duran D, Ertekin M, Demšar A, Bizjak M. Functionalization of Woven Fabrics with PBT Yarns. Polymers. 2021; 13 (2), 260: 1-19. https://doi.org/10.3390/polym13020260

Rijavec T, Bukošek V. Novel fibres for the 21st Century. Tekstilec. 2009; 47: 13-25. http://www.tekstilec.si/wp-content/uploads/2009/11/Novel-Fibres-for-the-21st-Century.pdf

Iqbal K, Sun D. Development of thermal stable multifilament yarn containing micro-encapsulated phase change materials. Fibers Polym. 2015; 16 (5): 1156-1162. https://doi.org/10.1007/s12221-015-1156-9 .

Ng WS, Hu H. Woven Fabrics Made of Auxetic Plied Yarns. Polymers. 2018; 10 (2): 226. https://doi.org/10.3390/polym10020226 .

Kostajnšek K, Urbas R, Dimitrovski K. A New Simplified Model for Predicting the UV-Protective Properties of Monofilament PET Fabrics. Autex Res J. 2019; 19 (3): 263-270. https://doi.org/10.1515/aut-2018-0041 .

Kocić AA, Bizjak M, Popović D, Poparić, GB, Stanković, SB. UV protection afforded by textile fabrics made of natural and regenerated cellulose fibres. J Clean Prod. 2019; 228: 1229-1237. https://doi.org/10.1016/j.jclepro.2019.04.355 .

Ghane M, Ghorbani E. Investigation into the UV-Protection of Woven Fabrics Composed of Metallic Weft Yarns. Autex Res J. 2016; 16 (3): 154-159. https://doi.org/10.1515/aut-2015-0021 .

Ng MCF, Zhou J. A Study on Figured Double-face Jacquard Fabric with Full-color Effect. Text Res J. 2009; 79 (10): 930-936. https://doi.org/10.1177/0040517508095603 .

Bilisik K, Demir F. Dimensional and mechanical characterization of newly developed denim fabrics based on experimentally determined property-structural pattern relations for upholstery applications. Fibers Polym. 2010; 11: 521-530. https://doi.org/10.1007/s12221-010-0521-y .

Bizjak Bojič M, Dimitrovski K. The Role of Technological Parameters at Woven Fabrics Construction. Int J Polym Mater. 2000; 47(4): 603-612. https://doi.org/10.1080/00914030008031315 .

Kostajnšek K, Dimitrovski K. Multilayer cotton fabric porosity and its influence on permeability properties. Tekstilec. 2018; 61 (4): 254-264.https://doi.org/10.14502/Tekstilec2018.61.254-264 .

Zampetakis A, Katsaros G. Optimization of wear comfort parameters for summer cloths Ind. Textila. 2008; 59(5): 213-220. https://www.researchgate.net/publication/294419954_Optimizing_the_wear_comfort_parameters_for_summer_clothes .

Dimitrovski K. Določanje odprte površine za pretok v tekstilijah. Tekstilec. 1997; 40 (1-2): 5-10. (in Slovenian)

Dimitrovski K. Metode za določanje poroznosti v tekstilijah. Tekstilec.1995; 38 (5):121-123. (in Slovenian)

Kostajnšek K., Zupin Ž, Hladnik A, Dimitrovski K. Optical assessment of porosity parameters in transparent woven fabrics. Polymers. 2021; 13(3): 408. https://doi.org/10.3390/polym13030408 .

Jakšić D, Jakšić N. Assessment of Porosity of flat textile fabric. Text Res J. 2007; 77 (2): 105-110. https://doi.org/10.1177/0040517506065892 .

Dobnik Dubrovski P. Volume porosity of woven. Text Res J. 2000; 70: 915-919. https://doi.org/10.1177/004051750007001011

Arahne CAD/CAM for weaving. https://www.arahne.si/sl/. Accessed April 7, 2022.

SIST EN 1049-2: Textiles - Woven fabrics - Construction - Methods of analysis - Part 2: Determination of number of threads per unit length (ISO 7211-2:1984 modified). 1999

SIST EN 12127: Textiles - Fabrics - Determination of mass per unit area using small samples. 1999

SIST EN ISO 5084: Textiles - Determination of thickness of textiles and textile products. 1999

SIST EN ISO 9237: Textiles - Determination of permeability of fabrics to air. 1999

DIN 52 612: Testing of Thermal Insulating Materials; Determination of Thermal Conductivity by the Guarded Hot Plate Apparatus; Test Procedure and Evaluation. 1979

EN 13758-1:2001: Textiles - Solar UV protective properties - Part 1: Method of test for apparel fabrics. 2006

Tàpias M, Ralló M, Escofet J, Algaba I, Riva A. Objective measure of woven fabric’s cover factor by Image processing. Text Res J. 2010; 80: 35-44. https://doi.org/10.1177/0040517509104471 .

Ragab A, Fouda A, El-Deeb H, Abou-Taleb H. Determination of Pore Size. Porosity and Pore Size Distribution of Woven Structures by Image Analysis Techniques. J Textile Sci Eng. 2017; 7: 1-9. https://doi.org/10.4172/2165-8064.1000314 .

Kostajnšek K, Dimitrovski K, Hladnik A. Use of image analysis for the determination of open area fraction in woven fabrics. In: Proceedings of 13th Autex Conference. Dresden, Germany, 2013, pp. 1-5.

Kostajnšek K, Zupin Ž, Hladnik A, Dimitrovski K. Optical Assessment of Porosity Parameters in Transparent Woven Fabrics. Polymers. 2021; 13(3): 408. https://doi.org/10.3390/polym13030408.