Adsorpcioni predtretman otpadnog jestivog ulja primenom kreča za sintezu metil estara masnih kiselina Naučni rad

Glavni sadržaj članka

Apstrakt

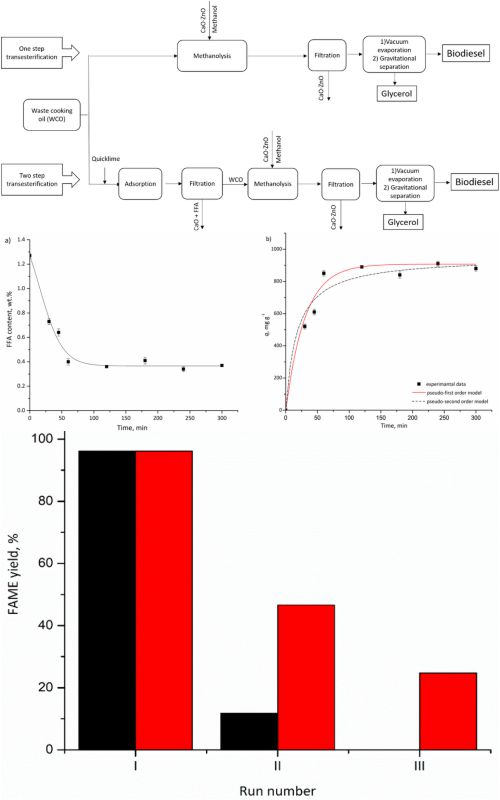

Sinteza biodizela iz različitih biljnih ulja ostvaruje se transesterifikacijom triglicerida sa metanolom ili reakcijom koja se obično definiše kao metanoliza. Korišćenje ulja lošijeg kvaliteta, kao što je otpadno jestivo ulje (engl. waste cooking oil, WCO), prate neželjene sporedne reakcije kao posledica povećanog sadrđžaja slobodnih masnih kiselina (engl. free fatty acids, FFA) i vode. Prisustvo FFA u tim uljima obično zahteva fazu prethodne obrade pre nego što se ulje podvrgne procesu transesterifikacije. U ovom radu istražena je heterogeno kanalizovana metanoliza WCO sa i bez predtretmana. Uklanjanje FFA iz WCO obavljeno je korišćenjem samo kreča ili uz dodatak male količine metanola (molarni odnos FFA prema metanolu = 1:3). Dobijeni rezultati su pokazali da se u predtretmanu WCO krečom na 30 °C nakon 1 h može smanjiti sadržaj FFA za 72%, dok je određeno da je ravnotežni kapacitet adsorpcije 910 mg g-1. Predtretman adsorpcijom, kao jednostavnom operacijom, korišćenjem jeftinog kreča pod blagim uslovma, pozitivno je uticao na brzinu reakcije transesterifikacije s CaO∙ZnO kao katalizatorom, omogućujući postizanje preko 96 % prinosa biodizela za samo 15 min, u poređenju sa potrebnim vremenskim periodom od 1 h za postizanje istog prinosa iz ulja bez predtretmana. Nadalje, prethodno tretirano WCO omogućuje povećan broj ciklusa ponovne upotrebe katalizatora i ukupnu uštedu potrebne količine katalizatora. Ova studija je pokazala da je kreč ekonomičan, ekološki prihvatljiv i održiv materijal za uklanjanje FFA iz WCO.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200135

Reference

Enweremadu CC, Mbarawa MM, Technical aspects of production and analysis of biodiesel from used cooking oil—A review. Renew Sust Energ Rev. 2009; 13: 2205–2224. https://doi.org/10.1016/j.rser.2009.06.007

Maddikeri GL, Pandit AB, Gogate PR, Intensification Approaches for Biodiesel Synthesis from Waste Cooking Oil: A Review. Ind Eng Chem Res. 2012; 51: 14610−14628. https://doi.org/10.1021/ie301675j

Yaakob Z, Mohammad M, Alherbawi M, Alam Z, Sopian K, Overview of the production of biodiesel from waste cooking oil. Renew Sust Energ Rev. 2013; 18: 184–193. https://doi.org/10.1016/j.rser.2012.10.016

Refaat AA, Different techniques for the production of biodiesel from waste vegetable oil. Int J Environ Sci Tech. 2010; 7(1): 183–213. https://doi.org/10.1007/BF03326130

Çanakçi M, Van Gerpen J, A pilot plant to produce biodiesel from high free fatty acid feedstocks Trans ASABE. 2003; 46: 945–954. https://doi.org/10.13031/2013.13949

Corro G, Tellez N, Jimenez T, Tapia A, Banuelos F, Vazquez-Cuchillo O, Biodiesel from waste frying oil. Two step process using acidified SiO2 for esterification step. Catal Today 2011; 166: 116–122. https://doi.org/10.1016/j.cattod.2010.09.011

Wang Y, Ou S, Liu P, Zhang Z, Preparation of biodiesel from waste cooking oil via two-step catalyzed process. Energy Convers Manag. 2007; 48: 184–188. https://doi.org/10.1016/j.enconman.2006.04.016

Cvengros J, Cvengrosova Z, Used Frying Oils and Fats and their Utilization in the Production of Methyl Esters of Higher Fatty Acids. Biomass Bioenerg. 2004; 27: 173–181. https://doi.org/10.1016/j.biombioe.2003.11.006

Díaz L, Brito A, FFA Adsorption from Waste Oils or Non-Edible Oils onto an Anion Exchange Resin as Alternative Method to Esterification Reaction Prior to Transesterification Reaction for Biodiesel Production. J Adv Chem Eng. 2014; 4: 105. http://dx.doi.org/10.4172/2090-4568.1000105

Demirbas A, Sari A, Isildak O, Adsorption thermodynamics of stearic acid onto bentonite. J Hazard Mater. 2006; 135: 226–231. https://doi.org/10.1016/j.jhazmat.2005.11.056

Sari A, Iþýldak Ö, Adsorption properties of stearic acid onto untreated kaolinite. Bull Chem Soc Ethiop. 2006; 20(2): 259–267. https://doi.org/10.1016/10.4314/bcse.v20i2.61410

Bayrak Y, Application of Langmuir isotherm to saturated fatty acid adsorption. Microporous and Mesoporous Mater. 2006; 87: 203–206. https://doi.org/10.1016/j.micromeso.2005.08.009

Sari A, Soylake M, Equilibrium and thermodynamic studies of stearic acid adsorption on Celtek clay. J Serb Chem Soc. 2007; 72(5): 485–494. https://doi.org/10.2298/JSC0705485S

Ilgen O, Adsorption of oleic acid from sunflower oil on Amberlyst A26 (OH). Fuel Process Technol. 2014; 118: 69–74. http://dx.doi.org/10.1016/j.fuproc.2013.08.012

Maddikeri GL, Pandit AB, Gogate PR, Adsorptive Removal of Saturated and Unsaturated Fatty Acids Using Ion-Exchange Resins. Ind Eng Chem Res. 2012; 51: 6869−6876. http://dx.doi.org/dx.doi.org/10.1021/ie3000562

Jamal Y, Boulanger BO, Separation of oleic acid from soybean oil using mixed-bed resins. J Chem Eng Data 2010; 55: 2405–2409. http://dx.doi.org/10.1021/je900829c

Ilgen O, Dulger HS, Removal of oleic acid from sunflower oil on zeolite 13X: Kinetics, equilibrium and thermodynamic studies. Ind Crops Prod. 2016; 81: 66–71. http://dx.doi.org/10.1016/j.indcrop.2015.11.050

Pereira MRDN, Salviano AB, de Medeiros TPV, Santos MRD, Cibaka TE, de Andrade MHC, de Oliveira Porto A, Lago RM. Ca(OH)2 nanoplates supported on activated carbon for the neutralization/removal of free fatty acids during biodiesel production. Fuel 2018; 221: 469–475. http://dx.doi.org/10.1016/j.fuel.2018.01.123

Nor Shafizah I, Irmawati R, Omar H, Yahaya M, Alia Aina A, Removal of free fatty acid (FFA) in crude palm oil (CPO) using potassium oxide/dolomite as an adsorbent: Optimization by Taguchi method. Food Chem. 2022; 373: 131668. https://doi.org/10.1016/j.foodchem.2021.131668

Díaz L, Mertes L, Brito A, Rodríguez KE, Valorization of energy crop shells as potential green adsorbents for free fatty acid removal from oils for biodiesel production. Biomass Convers Bioref. 2022; 12: 655–668. https://doi.org/10.1007/s13399-020-01089-y

Cano М., Sbargoud К., Allard Е., Larpent C, Magnetic separation of fatty acids with iron oxide nanoparticles and application to extractive deacidification of vegetable oils. Green Chem. 2012; 14: 1786–1795. https://doi.org/10.1039/c2gc35270b

Kalapathy U, Proctor A, New Method for Free Fatty Acid Reduction in Frying Oil Using Silicate Films Produced from Rice Hull Ash. JAOCS. 2000; 77(6): 593–598. https://doi.org/10.1007/s11746-000-0095-4

Clowutimon W, Kitchaiya P, Assawasaengrat P, Adsorption of Free Fatty Acid from Crude Palm Oil on Magnesium Silicate Derived From Rice Husk. Eng J. 15 2011; 15(3):15–25. https://doi.org/10.4186/ej.2011.15.3.15

Kim M, Yoon SH, Choi E, Gil B, Comparison of the adsorbent performance between rice hull ash and rice hull silica gel according to their structural differences. LWT-Food Sci Technol. 2008; 41: 701–706. https://doi.org/10.1016/j.lwt.2007.04.006

Topallar H, Bayrak Y, Investigation of Adsorption Isotherms of Myristic, Palmitic and Stearic Acids on Rice Hull Ash. Turk J Chem. 1999; 23: 193–198.

Adam F, Chua JH, The adsorption of palmitic acid on rice husk ash chemically modified with Al(III) ion using the sol–gel technique. J Colloid Interface Sci. 2004; 280: 55–61. https://doi.org/10.1016/j.jcis.2004.07.006

Bao Y, Zhou Q, Zhang M, Zhang H, Luan Q, Zhou W, Tang H, Huang F, Wet-spun nanoTiO2/chitosan nanocomposite fibers as efficient and retrievable absorbent for the removal of free fatty acids from edible oil. Carbohydr Polym 2019; 210: 119–126. https://doi.org/10.1016/j.carbpol.2019.01.035

Adewuyi A, Ogagbolo AI, Lau WJ, Oderinde RA, Synthesis of spinel ferrite and its role in the removal of free fatty acids from deteriorated vegetable oil. Chinese Journal of Chemical Engineering 2021; 40: 78–87. https://doi.org/10.1016/j.cjche.2020.08.054

Lukić I, Kesić Ž, Maksimović S, Zdujić M, Liu H, Krstić J, Skala D, Kinetics of sunflower and used vegetable oil methanolysis catalyzed by CaO·ZnO. Fuel 2013; 113: 367–78. https://doi.org/10.1016/j.fuel.2013.05.093

Kesić Ž, Lukić I, Brkić D, Rogan J, Zdujić M, Liu H, Skala D, Mechanochemical preparation and characterization of CaO·ZnO used as catalyst for biodiesel synthesis. Appl Catal A 2012; 427–428: 58–65. https://doi.org/10.1016/j.apcata.2012.03.032

Miladinović MR, Krstić JB, Tasić MB, Stamenković OS, Veljković VB, A kinetic study of quicklime-catalyzed sunflower oil methanolysis. Chem Eng Res Des. 2014; 92(9) 1740–1752. https://doi.org/10.1016/j.cherd.2013.11.023

Lukić I, Kesić Ž, Maksimović S, Zdujić M, Krstić J, Skala D. Kinetics of heterogeneous methanolysis of sunflower oil with CaO∙ZnO catalyst: Influence of different hydrodynamic conditions. Chem. Ind. Chem. Eng. Q. 2014; 20: 425–439. https://doi.org/10.2298/CICEQ130514025L

Qiu H, Lv L, Pan B, Zhang Q, Zhang W, Zhang Q, Critical review in adsorption kinetic models. J Zhejiang Univ Sci A 2009; 10(5)716–724. https://doi.org/10.1631/jzus.A0820524

Song G, Zhu X, Chen R, Liao Q, Ding Y, Chen L, An investigation of CO2 adsorption kinetics on porous magnesium oxide. Chem Eng J. 2016; 283: 175–183.

Ho YS, McKay G, Pseudo-second order model for sorption processes. Process Biochem. 1999: 34(5): 451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Filopoulou A, Vlachou S, Boyatzis SC, Fatty Acids and Their Metal Salts: A Review of Their Infrared Spectra in Light of Their Presence in Cultural Heritage. Molecules 2021; 26(19): 6005. https://doi.org/10.3390/molecules26196005

Lu Y, Miller JD, Carboxyl Stretching Vibrations of Spontaneously Adsorbed and LB-Transferred Calcium Carboxylates as Determined by FTIR Internal Reflection Spectroscopy. J Colloid Interface Sci. 2002; 256: 41–52. https://doi.org/doi:10.1006/jcis.2001.8112

Zul NA, Ganesan S, Hamidon TS, Oh W-D, Hussin MH, A review on the utilization of calcium oxide as a base catalyst in biodiesel production. J Environ Chem Eng 2021: 9(4): https://doi.org/10.1016/j.jece.2021.105741

Lin Y-C, Amesho KTT, Chen C-E, Cheng P-C, Chou F-C, A cleaner process for green biodiesel synthesis from waste cooking oil using recycled waste oyster shells as a sustainable base heterogeneous catalyst under the microwave heating system. Sustain Chem Pharm 2020; 17: 100310 https://doi.org/10.1016/j.scp.2020.100310

Aghel B, Mohadesi M, Ansari A, Maleki M, Pilot-scale production of biodiesel from waste cooking oil using kettle limescale as a heterogeneous catalyst. Renew Energy 2019; 142: 207–214. https://doi.org/10.1016/j.renene.2019.04.100

Yusuff AS, Gbadamosi AI, Atray N, Development of a zeolite supported CaO derived from chicken eggshell as active base catalyst for used cooking oil biodiesel production. Renew Energy 2022; 197: 1151–1162. https://doi.org/10.1016/j.renene.2022.08.032

Borah MJ, Das A, Das V, Bhuyan N, Deka D, Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste egg shell derived CaO nanocatalyst. Fuel 2019; 242: 345–354. https://doi.org/10.1016/j.fuel.2019.01.060.

Torkzaban S, Feyzi M, Norouzi L, A novel robust CaO/ZnFe2O4 hollow magnetic microspheres heterogenous catalyst for synthesis biodiesel from waste frying sunflower oil, Renew Energy 2022; 200: 996–1007. https://doi.org/10.1016/j.renene.2022.09.077.

Foroutan R, Mohammadi R, Razeghi J, Ramavandi B, Biodiesel production from edible oils using algal biochar/CaO/K2CO3 as a heterogeneous and recyclable catalyst. Renew Energy 2021; 168: 1207–1216. https://doi.org/10.1016/j.renene.2020.12.094

López Granados M, Martín Alonso D, Sádaba I, Mariscal R, Ocón P, Leaching and homogeneous contribution in liquid phase reaction catalysed by solids: the case of triglycerides methanolysis using CaO. Appl Catal B 2009; 89: 265–272. https://doi.org/10.1016/j.apcatb.2009.02.014

Pavlović SM, Marinković DM, Kostić MD, Janković-Častvan IM, Mojović LjV, Stanković MV, Veljković VB, A CaO/zeolite-based catalyst obtained from waste chicken eggshell and coal fly ash for biodiesel production. Fuel 2020; 267: 117171. https://doi.org/10.1016/j.fuel.2020.117171.

Kostić MD, Bazargan A, Stamenković OS, Veljković VB, McKay G, Optimization and kinetics of sunflower oil methanolysis catalyzed by calcium oxide-based catalyst derived from palm kernel shell biochar. Fuel 2016; 163: 304–313. 10.1016/j.fuel.2015.09.042.

Acosta PI, Campedelli RR, Correa EL, Bazani HAG, Nishida EN, Souza BS, Mora JR, Efficient production of biodiesel by using a highly active calcium oxide prepared in presence of pectin as heterogeneous catalyst. Fuel 2020; 271: 117651. https://doi.org/10.1016/j.fuel.2020.117651.

López Granados M, Martín Alonso D, Sádaba I, Mariscal R, Ocón P, Surface chemical promotion of Ca oxide catalysts in biodiesel production reaction by the addition of monoglycerides, diglycerides and glycerol. J Catal 2010; 276: 229–236. https://doi.org/10.1016/j.jcat.2010.09.016