Biogasoline synthesis by catalytic cracking of used cooking oil catalysed by chicken eggshell-based CaO impregnated onto γ−Al2O3 Original scientific paper

Main Article Content

Abstract

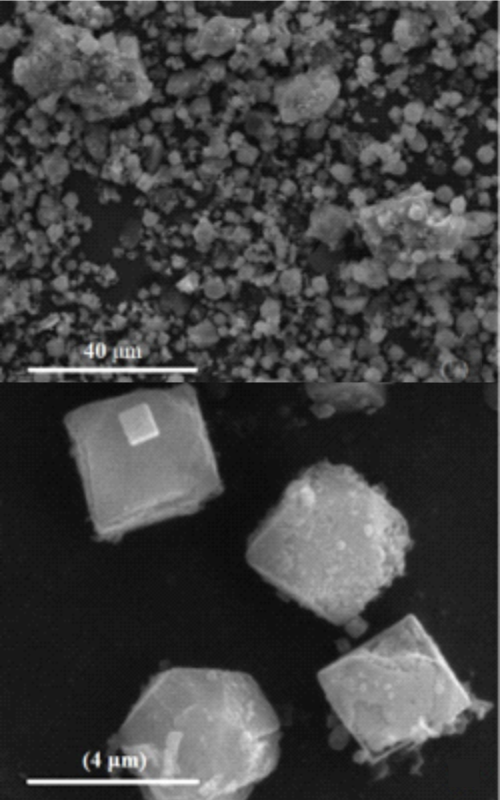

This research aims to synthesize biogasoline from used cooking oil using a catalyst of chicken eggshell based CaO impregnated with γ-Al2O3 through catalytic cracking, as well as to characterize the final product. Cracking optimization was carried out by varying the catalyst calcination temperature (650, 750 and 850 °C) and the catalyst concentration (1, 2 and 3 wt.%). The stages of this research were (1) characterization of used cooking oil (density, viscosity, refractive index, and iodine number) (2) synthesis of the CaO/γ-Al2O3, (3) catalytic cracking of used cooking oil with the use of the synthesized catalyst, and (4) characterization and identification of biogasoline. The results showed that the optimum condition for catalytic cracking was obtained at the calcination temperature of 650 °C. The synthesized biogasoline has the following characteristics, i.e. density of 0.776 g mL-1, viscosity of 1.84 mm2 s-1, a refractive index of 1.43, and the iodine number of 22.85 g I2 per 100 g. The synthesized biogasoline contained alkane, alkene and carboxylic acid compounds, C2-C19. This composition was dominated by compounds belonging to biogasoline (C5-C12) amounting to 94.5 wt.% as confirmed by gas chromatography-mass spectrometry analyses.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

References

[1] Davies A, Simmons MD. Demand for ‘advantaged’ hydrocarbons during the 21st century energy transition. Energy Reports. 2021; 7: 4483-4497. https://doi.org/10.1016/j.egyr.2021.07.013

[2] Diputra IGYM, Sunardi, Siyaranamual MD. The correlation between formal education and knowledge of used cooking oil management at Kampung Tersenyum society in South Jakarta. E3S Web Conf. 2024; 495: 03006. https://doi.org/10.1051/e3sconf/202449503006

[3] Zein YM, Anal AK, Prasetyoko D, Qoniah I. Biodiesel Production from Waste Palm Oil Catalyzed by Hierarchical ZSM-5 Supported Calcium Oxide. Indones J Chem. 2016; 16(1): 98-104. https://doi.org/10.22146/ijc.21184

[4] Ge S, Ganesan R, Sekar M, Xia C, Shanmugam S, Alsehli M, Brindhadevi K. Blending and emission characteristics of biogasoline produced using CaO/SBA-15 catalyst by cracking used cooking oil. Fuel. 2022; 307: 121861. https://doi.org/10.1016/j.fuel.2021.121861

[5] Mampuru MB, Nkazi DB, Mukaya HE. Hydrocracking of waste cooking oil into biogasoline in the presence of a bi-functional Ni-Mo/alumina catalyst. Energy Sources, Part A Recover Util Environ Eff. 2020; 42(20): 2564-2575. https://doi.org/10.1080/15567036.2019.1610527

[6] Hassan SN, Nurdin S, Yaakob Z, Mahmud MS. Biogasoline synthesis via fluid catalytic cracking of waste cooking oil using treated eggshell. IOP Conf Ser Mater Sci Eng. 2020; 736(2): 22069. https://doi.org/10.1088/1757-899X/736/2/022069

[7] Santoso A, Sumari, Joharmawan R, Hutami LB. Catalytic cracking of waste frying oil using Ni-Fe/activated zeolite catalyst as a source of renewable energy. IOP Conf Ser Mater Sci Eng. 2019; 509: 12009. https://doi.org/10.1088/1757-899x/509/1/012009

[8] Santoso A, Mulyaningsih A, Sumari S, Retnosari R, Aliyatulmuna A, Pramesti IN, Asrori MR. Catalytic cracking of off grade crude palm oil to biogasoline using Co-Mo/α-Fe2O3 catalyst. Energy Sources, Part A Recover Util Environ Eff. 2023; 45(1): 1886-1899. https://doi.org/10.1080/15567036.2023.2183998

[9] A’issyah EWN, Santoso A, Aliyatulmuna A. Synthesis Bio-gasoline from Crude Palm Oil Offgrade via Catalytic Cracking Using CaO/α-Fe2O3 Heterogeneous Catalyst. E3S Web Conf. 2024; 481. https://doi.org/10.1051/e3sconf/202448101003

[10] Hassan SN, Sani YM, Abdul Aziz AR, Sulaiman NMN, Daud WMAW. Biogasoline: An out-of-the-box solution to the food-for-fuel and land-use competitions. Energy Convers Manag. 2015; 89: 349-367. https://doi.org/10.1016/j.enconman.2014.09.050

[11] Xu J, Jiang J, Chen J, Sun Y. Biofuel production from catalytic cracking of woody oils. Bioresour Technol. 2010; 101(14): 5586-5591. https://doi.org/10.1016/j.biortech.2010.01.148

[12] Zhang G, Yu F, Wang W, Wang J, Ji J. Influence of Molten Salts on Soybean Oil Catalytic Pyrolysis with/without a Basic Catalyst. Energy & Fuels. 2014; 28(1): 535-541. https://doi.org/10.1021/ef4015845

[13] Ayodeji AA, Modupe OE, Rasheed B, Ayodele JM. Data on CaO and eggshell catalysts used for biodiesel production. Data Br. 2018; 19: 1466-1473. https://doi.org/10.1016/j.dib.2018.06.028

[14] Santoso A, Kusumah TN, Sumari S, Wijaya AR, Retnosari R, Rachman IB, Marfuah S, Roy Asrori M. Synthesis of biodiesel from waste cooking oil using heterogeneous catalyst of Na2O/γ-Al2O3 assisted by ultrasonic wave. AIMS Energy. 2022; 10(5): 1059-1073. https://doi.org/10.3934/energy.2022049

[15] Stuart NM, Sohlberg K. The Microstructure of γ-Alumina. Energies. 2021; 14(20): 6472. https://doi.org/10.3390/en14206472

[16] Feng R, Liu S, Bai P, Qiao K, Wang Y, Al-Megren HA, Rood MJ, Yan Z. Preparation and Characterization of γ-Al2O3 with Rich Brønsted Acid Sites and Its Application in the Fluid Catalytic Cracking Process. J Phys Chem C. 2014; 118(12): 6226-6234. https://doi.org/10.1021/jp411405r

[17] Wijanarko A, Mawardi DA, Nasikin M. Biogasoline Production from Palm Oil Via Catalytic Hydrocracking over Gamma-Alumina Catalyst. Makara J Technol. 2006; 10(2): 51-60. https://doi.org/10.7454/mst.v10i2.423

[18] Rasyid R, Prihartantyo A, Mahfud M, Roesyadi A. Hydrocracking of Calophyllum inophyllum Oil With Non-sulfide CoMo Catalysts. Bull Chem React Eng Catal. 2015; 10(1): 61-69. https://doi.org/10.9767/bcrec.10.1.6597.61-69

[19] Marbun MJ, Kurniawansyah F, Prajitno DH, Roesyadi A. Production of Diethyl Ether Over Cr-Co/γ-Al2O3 Catalyst. IOP Conf Ser Mater Sci Eng. 2019; 543(1): 12058. https://doi.org/10.1088/1757-899X/543/1/012058

[20] Oko S, Feri M. Pengembangan Katalis CaO dari Cangkang Telur Ayam dengan Impregnasi KOH dan Aplikasinya terhadap Pembuatan Biodiesel dari Minyak Jarak. J Teknol. 2019; 11(2): 103-109. https://doi.org/10.24853/jurtek.11.2.103-110

[21] Chauruka SR, Hassanpour A, Brydson R, Roberts KJ, Ghadiri M, Stitt H. Effect of mill type on the size reduction and phase transformation of gamma alumina. Chem Eng Sci. 2015; 134: 774-783. https://doi.org/10.1016/j.ces.2015.06.004

[22] Kalaycı T, Altuğ DT, Kınaytürk NK, Tunalı B. Characterization and potential usage of selected eggshell species. Sci Rep. 2025; 15, 6241. https://doi.org/10.1038/s41598-025-87786-y

[23] Ayoola HO, House SD, Bonifacio CS, Kisslinger K, Saidi WA, Yang JC. Evaluating the accuracy of common γ-Al2O3 structure models by selected area electron diffraction from high-quality crystalline γ-Al2O3. Acta Mater. 2020; 182: 257-566. https://doi.org/10.1016/j.actamat.2019.10.027

[24] Tang W, Yuan Y, Hu G, Zhu J, Dai Y, Zhang J, Fu C. Ammonium salt-assisted preparation of porous high-purity γ-Al2O3 with a high specific surface area. Ceram Int. 2024; 50(5): 7255-7265. https://doi.org/10.1016/j.ceramint.2023.11.294

[25] Asrori MR, Santoso A, Sumari S. Initial defect product on immiscible mixture of palm oil: Ethanol by amphiphilic chitosan/Zeolite LTA as optimization of microemulsion fuel. Ind Crops Prod. 2022; 180: 114727. https://doi.org/10.1016/j.indcrop.2022.114727