Predviđanje vulkanizacije gume korišćenjem veštačke neuronske mreže Stručni rad

Glavni sadržaj članka

Apstrakt

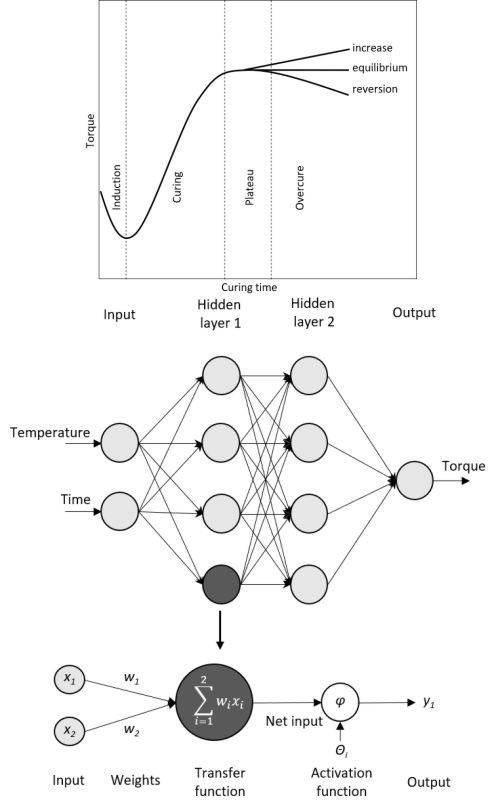

Za sprovođenje efikasnog procesa vulkanizacije u gumarskoj industriji neophodni su pouzdani reološki rezultati umrežavanja kaučukovih smeša. Stoga, osnovni cilj ovog rada bio je razvoj napredne veštačke neuronske mreže (engl. artificial neural network, ANN) za brzo i tačno predviđanje vulkanizacije komercijalno dostupne elastomerne smeše za dobijanje gumenih proizvoda. ANN je trenirana na prethodno određenim eksperimentalnim podacima obrtnog momenta u zavisnosti od vremena na pet različitih temperatura, u temperaturnom opsegu od 140 do 180 oC, sa korakom od 10 oC. ANN model je razvijen pomoću platforme za mašinsko učenje TensorFlow primenom Keras modela i programskog jezika Pajton (Python), gde su model i optimizator bili sekvencijalni model i adam, redom. Sledeće aktivacione funkcije: ReLU, sigmoidna i Softplus, korišćene su za minimizaciju greške, gde je ANN model sa Softplus funkcijom pokazao najtačnije rezultate predviđanja. Varirani su brojevi neurona i slojeva, gde je ANN model sa dva sloja, i 20 neurona u svakom sloju, dao najbolje rezultate. Predloženi ANN model je treniran na podacima dobijenim na temperaturama od 140, 160 i 180 oC, a zatim je korišćen za predviđanje zavisnosti obrtnog momenta od vremena za dve preostale temperature vulkanizacije u datom eksperimentalnom setu (150 i 170 oC). Dobijena rešenja su potvrđena kao tačna predviđanja upotrebom različitih numeričkih metoda, za sve ispitivane temperature, gde su vrednosti srednje apsolutno procentualno odstupanje (engl. mean absolute percentage error MAPE) i srednje kvadratno odstupanje (engl. mean squared error MSE) manje od 1,99% i 0,032 dN2 m2, redom.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Ghoreishy MHR. A state-of-the-art review on the mathematical modeling and computer simulation of rubber vulcanization process. Iran Polym J (English Ed). 2016;25:89–109. https://doi.org/10.1007/s13726-015-0405-5

Alwaan IM. Rheological characterization and modeling of vulcanization kinetics of natural rubber/starch blends. J Appl Polym Sci. 2018;135:27–9. https://doi.org/10.1002/app.46347

Leroy E, Souid A, Deterre R. A continuous kinetic model of rubber vulcanization predicting induction and reversion. Polym Test. 2013;32:575–82. https://doi.org/10.1016/j.polymertesting.2013.01.003

Erfanian MR, Anbarsooz M, Moghiman M. A three dimensional simulation of a rubber curing process considering variable order of reaction. Appl Math Model. 2016;40:8592–604. https://doi.org/10.1016/j.apm.2016.05.024

Ghoreishy MHR, Rafei M, Naderi G. Optimizationofthevulcanizationprocessofathickrubber article using an advanced computer simulation technique. Rubber Chem Technol. 2012;85:576–89. https://doi.org/10.5254/rct.12.88917

Khang TH, Ariff ZM. Vulcanization kinetics study of natural rubber compounds having different formulation variables. J Therm Anal Calorim. 2012;109:1545–53. https://doi.org/10.1007/s10973-011-1937-3

Zhao L, Hu X. A variable reaction order model for prediction of curing kinetics of thermosetting polymers. Polymer (Guildf). 2007;48:6125–33. https://doi.org/10.1016/j.polymer.2007.07.067

El Labban A, Mousseau P, Bailleul JL, Deterre R. Numerical natural rubber curing simulation, obtaining a controlled gradient of the state of cure in a thick-section part. AIP Conf Proc. 2007;907:921–6. https://doi.org/10.1063/1.2729631

Wang B, Ma JH, Wu YP. Application of artificial neural network in prediction of abrasion of rubber composites. Mater Des. 2013;49:802–7. https://doi.org/10.1016/j.matdes.2013.01.047

Yu Y, Adu K, Tashi N, Anokye P, Wang X, Ayidzoe MA. RMAF: Relu-Memristor-Like Activation Function for Deep Learning. IEEE Access. 2020;8:72727–41. https://doi.org/10.1109/ACCESS.2020.2987829

Schwartz GA. Prediction of rheometric properties of compounds by using artificial neural networks. Rubber Chem Technol. 2001;74:116–23. https://doi.org/10.5254/1.3547632

Karaaǧaç B, Inal M, Deniz V. Artificial neural network approach for predicting optimum cure time of rubber compounds. Mater Des. 2009;30:1685–90. https://doi.org/10.1016/j.matdes.2008.07.010

Bera O, Pavličević J, Ikonić B, Lubura J, Govedarica D, Kojić P. A new approach for kinetic modeling and optimization of rubber molding. Polym Eng Sci. 2021;61:879–90. https://doi.org/10.1002/pen.25636

Ghoreishy MHR, Rafei M, Naderi G. Optimization of the vulcanization process of a thick rubber article using an advanced computer simulation technique. Rubber Chem Technol. 2012;85:576–89. https://doi.org/10.5254/rct.12.88917

Vijayabaskar V, Gupta R, Chakrabarti PP, Bhowmick AK. Prediction of properties of rubber by using artificial neural networks. J Appl Polym Sci. 2006;100:2227–37. https://doi.org/10.1002/app.22356

Kazi MK, Eljack F, Mahdi E. Predictive ANN models for varying filler content for cotton fiber/PVC composites based on experimental load displacement curves. Compos Struct. 2020;254:112885. https://doi.org/10.1016/j.compstruct.2020.112885

Elkatatny S. Real-Time Prediction of Rheological Parameters of KCl Water-Based Drilling Fluid Using Artificial Neural Networks. Arab J Sci Eng. 2017;42:1655–65. https://doi.org/10.1007/s13369-016-2409-7

Saldaña M, Ayala L, Torres D, Toro N. Global sensitivity analyses of a neural networks model for a flotation circuit. Hem Ind. 2020;74:247–56. https://doi.org/10.2298/HEMIND20060523S

Abadi M, Barham P, Chen J, Chen Z, Davis A, Dean J, Devin M, Ghemawat S, Irving G, Isard M, Kudlur M, Levenberg J, Monga R, Moore S, Murray DG, Steiner B, Tucker P, Vasudevan V, Warden P, Wicke M, Yu Y, Zheng X. TensorFlow: A system for large-scale machine learning, Proceedings of the 12th USENIX Symposium on Operating Systems Design and Implementati. November 2–4, 2016, Savannah, GA, USA, pp. 265-283.

Sarang P. Artificial Neural Networks with TensorFlow 2. Artif Neural Networks with TensorFlow 2. 2021. https://doi.org/10.1007/978-1-4842-6150-7

Bezabeh BB, Mengistu AD. The effects of multiple layers feed-forward neural network transfer function in digital based ethiopian soil classification and moisture prediction. Int J Electr Comput Eng. 2020;10:4073–9. https://doi.org/10.11591/ijece.v10i4. pp 4073-4079

Dučić N, Ćojbašić Ž, Slavković R, Jordović B, Purenović J. Optimizacija hemijskog sastava u proizvodnji flotacijskih kugli zasnovana na inteligentnoj softverskoj detekciji. Hem Ind. 2016;70:603–12. https://doi.org/10.2298/HEMIND150715068D

Lecun Y, Bengio Y, Hinton G. Deep learning. Nature. 2015;521:436–44. https://doi.org/10.1038/nature14539

Nasr MS, Moustafa MAE, Seif HAE, El Kobrosy G. Application of artificial neural network (ANN) for the prediction of EL-AGAMY wastewater treatment plant performance-EGYPT. Alexandria Eng J. 2012;51:37–43. https://doi.org/10.1016/j.aej.2012.07.005

Chasiotis VK, Tzempelikos DA, Filios AE, Moustris KP. Artificial neural network modelling of moisture content evolution for convective drying of cylindrical quince slices. Comput Electron Agric. 2020;172:105074. https://doi.org/10.1016/j.compag. 2019.105074

Park S, Park H. ANN Based Intrusion Detection Model. vol. 927. Springer International Publishing.; 2019. https://doi.org/10.1007/978-3-030-15035-8_40

Ramalingam V V, Ragavendran R. Prediction of liver disease using artificial neural network with adam optimizer. J Crit Rev. 2020;7:1287–92. https://doi.org/10.31838/jcr.07.17.164