Ispitivanje mikrostrukture, tvrdoće i termijskih karakteristika legura u sistemu Sn-Bi Naučni rad

Glavni sadržaj članka

Apstrakt

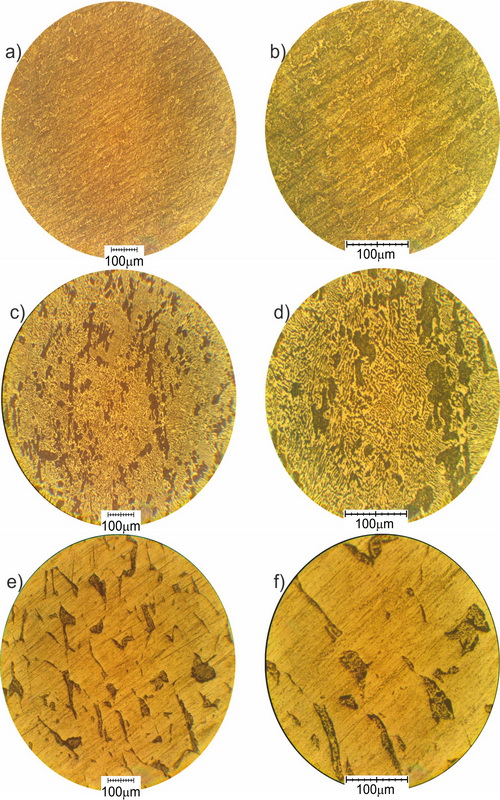

Zbog velike toksičnosti olova, bezolovni lemovi postali su glavni fokus elektronske industrije poslednjih godina. Zbog svojih povoljnih svojstava i niske cene, legure iz sistema Sn-Bi predstavljaju potencijalnu zamenu za legure Sn-Pb u lemljenju. Jedna od glavnih prednosti legura iz sistema Sn-Bi su niske temperature topljenja. Legure iz ovog sistema su takođe veoma atraktivne zbog dobre kompatibilnosti sa podlogama, niske temperature procesa, visoke pouzdanosti i potencijalne primene u vidu materijala termičkog sučelja. U ovom radu je urađena karakterizacija mikrostrukturnih i termijskih karakteristika, kao i merenje tvrdoće sedam Sn-Bi legura različitog sastava. Strukturna svojstva uzoraka analizirana su optičkom mikroskopijom i skenirajućom elektronskom mikroskopijom sa energetski disperzivnom spektrometrijom (SEM-EDS). Toplotna provodljivost uzoraka je ispitivana ksenon-fleš metodom (engl. xenon-flash method), a temperature faznih transformacija merene su diferencijalnom skenirajučom kalorimetrijom (engl. differential scanning calorimetry, DSC).

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Frongia F, Pilloni M, Scano A, Ardu A, Cannas C, Musinu A, Borzone G, Delsante S, Novakovic R, Ennas G, Ennas. Synthesis and melting behaviour of Bi, Sn and Sn–Bi nanostructured alloy. J. Alloys Compd. 2015; 623: 7-14. https://doi.org/10.1016/j.jallcom.2014.08.122

Ren G, Wilding I, Collins M. Alloying influences on low melt temperature SnZn and SnBi solder alloys for electronic interconnections. J. Alloys Compd. 2016; 665: 251-260. https://doi.org/10.1016/j.jallcom.2016.01.006

Zhang X. P, Yu C. B, Zhang Y. P, Shrestha S, Dorn L. Processing treatment of a lead-free Sn–Ag–Cu–Bi solder by rapid laser-beam reflowing and the creep property of its soldered connection. J. Mater. Process. Technol. 2007; 192: 539-542. https://doi.org/10.1016/j.jmatprotec.2007.04.072

Kanlayasiri K, Ariga T. Physical properties of Sn58Bi–xNi lead-free solder and its interfacial reaction with copper substrate. Mater. Des. 2015; 86: 371-378. https://doi.org/10.1016/j.matdes.2015.07.108

Sun H, Li Q, Chan Y. A study of Ag additive methods by comparing mechanical properties between Sn57. 6Bi0. 4Ag and 0.4 wt% nano-Ag-doped Sn58Bi BGA solder joints. J. Mater. Sci.: Mater. Electron. 2014; 25: 4380-4390. https://doi.org/10.1007/s10854-014-2177-7

Silva B, Garcia A, Spinelli J. Complex eutectic growth and Bi precipitation in ternary Sn-Bi-Cu and Sn-Bi-Ag alloys. J. Alloys Compd. 2017; 691: 600-605. https://doi.org/10.1016/j.jallcom.2016.09.003

Abtew M, Selvaduray G. Lead-Free Solders in Microelectronics. Mater. Sci. Eng. 2000; 27: 95-141. https://doi.org/10.1016/S0927-796X(00)00010-3

Braga M. H, Vizdal J, Kroupa A, Ferreira J, Soares D, Malheiros L. F. The experimental study of the Bi–Sn, Bi–Zn and Bi–Sn–Zn systems. Calphad. 2007; 31: 468–478. https://doi.org/10.1016/j.calphad.2007.04.004

Mokhtari O, Nishikawa H. Correlation between microstructure and mechanical properties of Sn–Bi–X solders. Mater. Sci. Eng. 2016; 651: 831-839. https://doi.org/10.1016/j.msea.2015.11.038

Zhao J, Qi L, Wang X, Wang L. Influence of Bi on microstructures evolution and mechanical properties in Sn–Ag–Cu lead-free solder. J. Alloys Compd. 2004; 375: 196-201. https://doi.org/10.1016/j.jallcom.2003.12.005

Li J, Mannan S, Clode M, Whalley D, Hutt D. Interfacial reactions between molten Sn–Bi–X solders and Cu substrates for liquid solder interconnects. Acta Mater. 2006; 54: 2907-2922. https://doi.org/10.1016/j.actamat.2006.02.030

Shen J, Pu Y, Yin H, Luo D, Chen J. Effects of minor Cu and Zn additions on the thermal, microstructure and tensile properties of Sn–Bi-based solder alloys. J. Alloys Compd. 2014; 614: 63-70. https://doi.org/10.1016/j.jallcom.2014.06.015

Shalaby R. Effect of silver and indium addition on mechanical properties and indentation creep behavior of rapidly solidified Bi–Sn based lead-free solder alloys. Mater. Sci. Eng., A. 2013; 560: 86-95. https://doi.org/10.1016/j.msea.2012.09.038

Miao H, Duh J. Microstructure evolution in Sn–Bi and Sn–Bi–Cu solder joints under thermal aging. Mater. Chem. Phys.. 2013; 71: 255-271. https://doi.org/10.1016/S0254-0584(01)00298-X

Peng Y, Deng K. Fabrication of reduced graphene oxide nanosheets reinforced Sn–Bi nanocomposites by electro-chemical deposition. Compos. Part A Appl. Sci. Manuf. 2015; 73: 55–62. https://doi.org/10.1016/j.compositesa.2015.03.006

Billah M, Chen Q. Thermal conductivity of Ni-coated MWCNT reinforced 70Sn-30Bi alloy. Compos. B. Eng. 2017; 129: 162-168. https://doi.org/10.1016/j.compositesb.2017.07.071

Wang J, Wei H, He P, Lin T, Lu F. Microstructure and mechanical properties of tin-bismuth solder reinforced by aluminum borate whiskers. J. Electron. Mater. 2015; 44: 3872-3879. https://doi.org/10.1007/s11664-015-3896-0

Peng Y, Deng K. Study on the mechanical properties of the novel Sn–Bi/Graphene nanocomposite by finite element simulation. J. Alloys Compd. 2015; 625: 44-51. https://doi.org/10.1016/j.jallcom.2014.11.110

Lai Z, Ye D. Microstructure and fracture behavior of non eutectic Sn–Bi solder alloys. J. Mater. Sci.: Mater. Electron.2016; 27: 3182-3192. https://doi.org/10.1007/s10854-015-4143-4

Silva B, Reinhart G, Nguyen-Thi H, Mangelinck-Noël N, Garcia A, Spinelli J. Microstructural development and mechanical properties of a near-eutectic directionally solidified Sn–Bi solder alloy. Mater. Charact. 2015; 107: 43-53. https://doi.org/10.1016/j.matchar.2015.06.026

Gao L, Wang J, Lin T, He P, Lu F. Improvement of microstructure and mechanical properties of Sn-58Bi alloy with La2O3. In: 14th International Conference on Electronic Packaging Technology. Dalian, China, 2013, pp. 193-195.

Osório W, Peixoto L, Garcia L, Mangelinck-Noël N, Garcia A. Microstructure and mechanical properties of Sn–Bi, Sn–Ag and Sn–Zn lead-free solder alloys. J. Alloys Compd. 2013; 572: 97-106. https://doi.org/10.1016/j.jallcom.2013.03.234

Guo Q, Zhao Z, Shen C. Comparison study on microstructure and mechanical properties of Sn-10Bi and Sn-Ag-Cu solder alloys and joints. Microelectron Reliab. 2017; 78: 72-79.

Wang Q, Cheng X, Li Y, Yu G, Liu Z. Microstructures and Thermal Properties of Sn–Bi–Zn–Ga Alloys as Heat Transfer and Heat Storage Materials. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019; 34: 676-683. https://doi.org/10.1007/s11595-019-2103-1

Wang F, Huang Y, ZhangZ, Yan C. Interfacial reaction and mechanical properties of Sn-Bi solder joints. Mater. 2017; 10: 920-936. https://doi.org/10.3390/ma10080920

Hua F, Zequn M, Glazer J. Eutectic Sn-Bi as an alternative to Pb-free solders. In: Proceedings of 48th Electronic Components and Technology Conference. Seattle, Washington, 1998, pp. 277-283.

Dong W, Shi Y, Xia Z, Lei Y, Guo F. Effects of trace amounts of rare earth additions on microstructure and properties of Sn-Bi-based solder alloy. J. Electron. Mater. 2008; 37: 982-991. https://doi.org/10.1007/s11664-008-0458-8

Morando C, Fornaro O, Garbellini O, Palacio H. Thermal properties of Sn-based solder alloys. J. Mater. Sci.: Mater. Electron. 2014; 25: 3440-3447. https://doi.org/10.1007/s10854-014-2036-6

Hu X, Li Y, Min Z. Interfacial reaction and growth behavior of IMCs layer between Sn–58Bi solders and a Cu substrate. J. Mater. Sci.: Mater. Electron. 2013; 24: 2027-2034 https://doi.org/10.1007/s10854-012-1052-7

Manasijević D, Balanović Lj, Ćosović V, Minić D, Premović M, Gorgievski M, Stamenković U, Talijan N. Thermal characterization of the In–Sn–Zn eutectic alloy. Metall. Mater. Eng. 2019; 25: 325-334. https://doi.org/10.30544/456

Marković B, Živković D, Manasijević D, Talijan N, Sokić M, Ćosović V. Phase Equilibria Calculation and Investigation of Hardness and Electrical Conductivity for Alloys in Selected Sections of Bi-Cu-Ni System. J. powder metall. min. 2012; 2:104 https://doi.org/10.4172/2168-9806.1000104

Kroupa A, Dinsdale A, Watson A, Vrestal J, Vízdal J, Zemanova A. The development of the COST 531 lead-free solders thermodynamic database. JOM. 2007; 59: 20-25. https://doi.org/10.1007/s11837-007-0084-6

Cao W, Chen S, Zhang F, Wu K, Yang Y, Chang Y, Schmid-Fetzer R, Oates W. PANDAT Software with PanEngine, PanOptimizer and PanPrecipitation for Multi-Component Phase Diagram Calculation and Materials Property Simulation. Calphad. 2009; 33: 328–342. https://doi.org/10.1016/j.calphad.2008.08.004

Vízdal J, Braga M, Kroupa A, Richter K, Soares D, Malheiros L, Ferreira J. Thermodynamic assessment of the Bi–Sn–Zn System. Calphad. 2007; 31: 438-448. https://doi.org/10.1016/j.calphad.2007.05.002

Parker W, Jenkins R, Butler C, Abbot G. Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity. J. Appl. Phys. 1961; 32: 1679-84. https://doi.org/10.1063/1.1728417

Engineering ToolBox, (2005). Thermal Conductivity of Metals, Metallic Elements and Alloys. [online] Available at: https://www.engineeringtoolbox.com/thermal-conductivity-metals-d_858.html. Accessed January 11, 2021.

Indium Corp. Indalloy® 281 Bi-Sn Solder Alloy. http://www.matweb.com/search/datasheet.aspx?matguid=967a4cd7871b46fa9128a29c303cf8be. Accessed January 11, 2021.

ASM Handbook Volume 2. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International; 1990.