Analysis of viscoelastic behavior of a filled elastomer under action of different loads

Main Article Content

Abstract

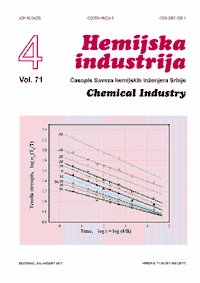

Mechanical properties of viscoelastic filled polymers strongly depend on temperature and strain rate and vary for several orders of magnitude. During service life, a viscoelastic body, especially carboxy-terminated polybutadiene (CTPB) composite solid rocket propellant grain, is subjected to many stress-inducing loads. Its structural integrity analysis (hereafter: "structural analysis"), unlike elastic bodies, is quite complex and sometimes impossible under the action of just a single load. An even greater problem occurs when multiple different types of loads act simultaneously. This study is based on a complete uniaxial mechanical characterization of a viscoelastic CTPB composite rocket propellant, made in MTI-Belgrade, whose results were used for the analysis of the propellant grain reliability. Through an example, this paper shows a behavior of the viscoelastic propellant grain when it is subjected to extremely different environmental loads at the same time. Similar explicit examples are difficult to found in the literature, except in the form of recommended principles for analysis. It is shown that the tensile strength under the action of fast load due to the pressure may be almost 20 times greater than the tensile strength under the slow temperature load. A probabilistic approach is presented in evaluation the reliability and service life. An example is shown for a rocket propellant grain as a viscoelastic body. The presented principles of the analysis can be applied to any arbitrary viscoelastic body in other areas.

Article Details

Issue

Section

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

M.L. Williams, P.J. Blatz, R.A. Schapery, Fundamental Studies Relating to Systems Analysis of Solid Propellants, Final report Galcit 101, 1961.

M.L. Williams, Structural analysis of viscoelastic mat-erials, AIAA J. 2 (1964) 785–808.

R.F. Landel, T.L. Smith, Viscoelastic properties of rubber-like composite propellants and filled elastomers, ARS J. 31 (1960) 599–608.

N. Gligorijević, V. Rodić, S. Živković, B. Pavković, M. Nikolić, S. Kozomara, S. Subotić, Mechanical characterization of composite solid rocket propellant based on hydroxy-terminated polybutadiene, Hem. Ind. 70 (2016) 581–594.

S. Brzić, Lj. Jelisavac, J. Galović, D. Simić, J. Petković, Viscoelastic properties of hydroxil-terminated poly-(butadiene)-based composite rocket propellants, Hem. Ind. 68 (2014) 435–443.

M.A. Miner, Cumulative damage in fatigue, J. Appl. Mech.-T. Asme 12 (1945) 159–164.

В.В. Москвитин, Сопротивление вязко-упругих материалов, изд. Наука, Москва, 1972.

J.E. Fitzgerald, W.L. Hufferd, Handbook for the Engineering Structural Analysis of solid Propellants, CPIA publication 214, 1971.

NASA SP-8073, Solid propellant grain structural integrity analysis, 1973.

N. Gligorijević, S. Živković, V. Rodić, S. Subotić, I. Gligorijević, Effect of cumulative damage on rocket motor service life, J. Energ. Mater. 33 (2015) 229–259.

N. Gligorijević, Strukturna analiza pogonskih punjenja raketnih motora sa čvrstim gorivom, Scientific-Technical Information 1 (2013) (in Serbian).

N. Gligorijević, Prilog strukturnoj analizi vezanog pogonskog punjenja raketnog motora sa čvrstom pogonskom materijom, Мagistarski rad, Mašinski fakultet u Beogradu, 1989 (in Serbian)

Agard-AR-350, Structural Assessment of Solid Propellant Grains, 1997.

M.L. Williams, R.F. Landel, J.D. Ferry, The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids, Ј. Аm. Chem. Soc. 77 (1955) 3701–3707.

N. Gligorijević, Istraživanje pouzdanosti i veka upotrebe raketnih motora sa čvrstom pogonskom materijom, PhD Thesis, Military Academy, Belgrade, 2010 (in Serbian).

N. Gligorijević, V. Rodić, R. Jeremić, S. Živković, S. Subotić, Structural analysis procedure for a case bonded solid rocket propellant grain, Scientific-Technical Review 61 (2011) 3–11.

R.А. Heller, М.P. Singh, Thermal storage life of solid-propellant motors, J. Spacecraft Rockets 20 (1983) 144–149.

R.А. Heller, М.P. Singh, H. Zibdeh, Environmental effects on cumulative damage in rocket motors, J. Spacecraft Rockets 22 (1985) 149–155.

S. Cerri, A.M. Bohn, K. Menke, L. Galfetti, Ageing behavior of HTPB based rocket propellant formulations, Cent. Eur. J. Energ. Mater. 6 (2009) 149–165.

N. Gligorijević, S. Živković, S. Subotić, B. Pavković, M. Nikolić, S. Kozomara, V. Rodić, Mechanical properties of HTPB composite propellants in the initial period of service life, Scientific-Technical Review 64 (2014) 8–16.

C.T. Liu, Cumulative Damage and Crack Growth in Solid Propellant, Media Pentagon Report No A486323, 1997.

J.F. Tormey, S.C. Britton, Effect of cyclic loading on solid propellant grain structures, AIAA J. 8 (1963) 1763–1770.

H.S. Zibdeh, R.A. Heller, Rocket motor service life calculations based on the first passage method, J. Spacecraft Rockets 26 (1989) 279–284.