Metoda modifikacije površine dupleks nerđajućih čelika postupkom boriranja Stručni rad

Glavni sadržaj članka

Apstrakt

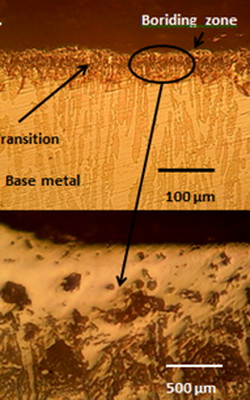

Ovaj rad prikazije istraživanje procesa boriranja dve vrste nerđajućeg čelika: UNS 32750 super dupleks nerđajući čelik i UNSS 31803 dupleks nerđajući čelik, u cilju poboljšanja osobina materijala i smanjenja mogućnosti katastrofalnih otkaza industrijskih komponenata. Upotreba dupleks nerđajućih čelika postala je raširena u postrojanjima za vađenje nafte i rafinerijama, u pomorstvu i u cevovodima, a zbog njihove povećane otpornosti na koroziju. Međutim ovi materijali su pokazuju slabu otpornost na habanja. Da bi se prevazišao ovaj problem, u ovom radu je korišćen proces borirawa. Procena efekata boriranja na mikrostrukturu i mehanička svojstva izvršena je pomoću skenirajuće elektronske i optičke mikroskopije, testova tvrdoće po Vickersu i testova habanja. Pokazano je da je postupak boriranja u trajanju od 4 sata rezultirao najvećom debljinom boriranog sloja, dajući maksimalnu površinsku tvrdoću super dupleks nerđajućeg čelika UNS 32750 od 1407 HV, odnosno 1201 HV dupleks nerđajućeg čelika UNSS 31803. Otpornosti na habanja boriranih materijala bile su i do 6 puta veće od onih kod netrfetiranih čelika. Pokazalo se da su borirani dupleks materijali pogodniji za proces boriranja jer pokazuju veću otpornost na habanje u poređenju sa super dupleks nerđajućim čelikom, zbog povećane debljine sloja gvozdenog borida.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Reference

Tahchieva AB, Llorca-Isern N, Cabrera JM. Review -Duplex and Super duplex Stainless Steels: Microstructure and Property Evolution by Surface Modification Processes. Metals. 2019; 9: 1-11. https://doi.org/10.3390/met9030347

Nilsson JO. Super duplex stainless steels. Mater Sci Technol. 1992; 8: 685 – 700. https://doi.org/10.1179/mst.1992.8.8.685

Hasan R, Jauhari I, Yunus SM, Ramdan RD, Masdek NRN. A Study on Boronizing of Duplex Stainless Steel. Key Eng Mater. 2006; 306: 887–892. https://doi.org/10.4028/www.scientific.net/KEM.306-308.887

Martins M, Casteletti LC. Heat treatment temperature influence on ASTM A890 GR 6A super duplex stainless steel microstructure. Mater Charact. 2005; 55: 225– 233. https://doi.org/10.1016/j.matchar.2005.05.008

Mestra A, Fargas G, Anglada M, Matew, Sliding wear behaviour of a duplex stainless steel, Key Eng Mater. 2009; 423: 125-130 https://doi.org/10.4028 /www.scientific.net/ KEM. A423.125

Nora R, Zinee TM, Abdelkader K, Youcef K, Ali O, Jiang X. Boriding and boronitrocarburizing effects on hardness, wear and corrosion behaviour of AISI 4130 steel. Revista Materia. 2019: 24: e-12327. https://doi.org/10.1590/S1517-707620190001.0609

Ozdemir O, Usta M, Bindal C, Ucisik HA. Hard iron boride (Fe2B) on 99.97 % pure iron. Vacuum. 2006; 80: 1391 – 1395. https://doi.org/10.1016/j.vacuum.2006.01.022

Jauhari I, Yusof HAM, Saidan R. Super plastic boronizing of duplex stainless steel under dual compression method. Mater Sci Eng A. 2011; 528: 8106-8110. https://doi.org/10.1016/j.msea.2011.07.054

Yuri FM, Andrey VS. Boriding of steel surface with beams of boron atoms. In: MATEC web of conference. Rostov State Transport University, Russia. 2018, 1-4. 326, 03004, 2018. https://doi.org/10.1051/matecconf/201822603004

Akshay AJ, Santosh SH. Pack boronizing of AISI 4140 steel: Boronizing mechanism and the role of container design. Mater Manufac Proc. 2014; 29: 1062-1072. https://doi.org/10.1080/10426914.2014.921705

Gunes I, Kanat S. Diffusion Kinetics and characterization of borided AISI D6 steel. Protec Met Phy Chem Surf. 2015; 51: 842-846. https://doi.org/10.1134/S2070205115050111

Haris NA, Alias SK, Abdullah B, Pahroraji HF, Najmie A. Abrasion and erosion wear properties of surface deformed stainless steel. ARPN J Eng Appl Sci. 2016; 11: 7717-7720.

Turkoglu T, Ay I. Analysis of boride layer thickness of borided AISI 430 by RSM. Int J Optim Cont: Theor Appl. 2019; 9: 39-44. https://doi.org/10.11121/ijocta.01.2019.00660

Boztepe MH, Bayramoglu M. Optimization of process parameter of boronized AISI 1050 steel using the Taguchi analysis. The 17th International Conference on Machine Design and Production, Bursa, Turkey, 2016, pp.1-11.

Kear G, Barker BD, Walsh FC. Electrochemical study of UNS S32550 super duplex stainless steel corrosion in turbulent seawater using rotating cylinder electrode. Corrosion. 2004; 60: 561-572. https://doi.org/10.5006/1.3287760

Gunes I, Uygunoglu T, Ergen A, Kisikcilar T, Aksoy E. Investigation of wear behaviour of borided DIN 20MoCr4 Steel. El-Cezeri J Sci Eng. 2015; 2: 53-58

Gunes I, Erdogan M, Giirhan Celik A. Corrosion behaviour and characterization of plasma nitrided and borided AISI M2 steel. Mater Res. 2014; 17: 612-618. https://doi.org/10.1590/S1516-14392014005000061

Campos-Silva I, Contla Pacheco AD, Ruiz Rios A, Martinez Trinidad J, Rodriguez Casro G, Meneses Amador A, Wong Angel WD. Effects of Scratch tests on the adhesive and cohesive properties of borided Inconel 718 superalloy. Surf Coat Technol. 2018; 349: 917-927. https://doi.org/10.1016/j.surfcoat.2018.05.086

Li P, Liu D, Bao W, Ma L, Duan Y. Surface characterization and diffusion model of pack borided TB2 titanium alloy. Ceram Int. 2018; 44: 18429-18437. https://doi.org/10.1016/j.ceramint.2018.07.060

Gunes I. Investigation of tribological properties and characterization of borided AISI 420 and AISI 5120 steels. Transac Ind Inst Met. 2013; 67, 359-365. https://doi.org/10.1007/s12666-013-0356-5

Krelling AP, Milan JC, Da Costa CE. Tribological behaviour of borided H13 steel with different boriding agents. Surf Eng. 2014; 31: 1-7. https://doi.org/10.1179/1743294414Y.0000000423

Sista V, Kahvecioglu O, Kartal G, Kim JH, Eryilmaz, EzdemirA. Evaluation of electro chemical boriding of Inconel 600. Surf Coat Technol. 2013; 215: 452-459.https://doi.org/10.1016/j.surfcoat.2012.08.083

Rahmani M, Eghlimi A, Shamania M. Evaluation of Microstructure and Mechanical Properties in Dissimilar Austenitic/Super Duplex Stainless Steel Joint. J Mater Eng Perfor. 2014; 23: 3745–3753. https://doi.org/10.1007/s11665-014-1136-z

Erdogan A. Investigation of high temperature dry sliding behaviour of borided H13 hot work steel with nanoboron powder. Surf Coat Technol. 2019; 357: 886-895. https://doi.org/10.1016/j.surfcoat.2018.10.066

Marcelo Martins AB, Casteletti LC. Heat treatment temperature influence on ASTM A890 GR 6A super duplex stainless steel microstructure. Mater Charact. 2005; 55: 225 – 233. https://doi.org/10.1016/j.matchar.2005.05.008

Aylor DM, Metals Handbook V-13, vol. 9, ASM Metals Park, OH, 1982, pp. 859–863

Ramakrishnan H, Balasundaram R. Experimental investigation of process parameters or pack boronizing of SS410 using anova and machine learning approaches. Surf Topogr: Metrol Prop. 2021; 9: 025046. https://doi.org/10.1088/2051-672X/ac0c8d

Salim S. Effects of boronizing process on the surface roughness and dimensions of AISI 1020, AISI 1040 and AISI 2714. J Mater Proc Technol. 2009; 209: 1736–1741. https://doi.org/10.1016/j.jmatprotec.2008.04.040