Hemijski sastav pirolizata dobijenih ko-pirolizom ostataka kukuruznih stabljika i plastičnog otpada kao osnova za proizvodnju ekološki održivih goriva Naučni rad

Glavni sadržaj članka

Apstrakt

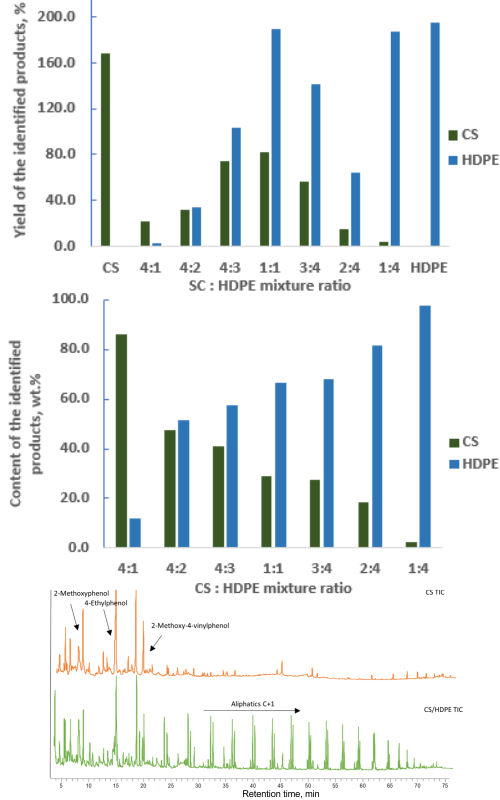

U ovom istraživanju izvršeni su eksperimenti pirolize i ko-pirolize uzoraka otpada lignoceluloznih kukuruznih stabljika (KS) i odabranih frakcija plastičnog otpada (polietilen velike gustine (engl. high density polyethylene, HDPE) i polistiren (PS)) u različitim masenim odnosima. Glavni cilj bio je procena uticaja sastava sirovine na prinos i sastav rezultujućih piroliznih proizvoda, razvijajući održivu metodu za upravljanje kako otpadom biomase tako i plastičnim otpadom kroz proizvodnju ulja i hemikalija. Reakcije ko-pirolize dokazale su sinergističke efekte između sirovina, pri čemu se plastični otpad pokazao kao donor vodonika poboljšavanjem prinosa proizvoda KS. Osim toga, proizvodi od plastičnog otpada su pokazali značajnu premoć nad onima od KS, čineći oko 66,6 i 85,6 % u odnosu 1:1 smeša KS/HDPE i KS/PS, redom. Ovo istraživanje pruža važne uvide u formiranje sintetičkih bio-ulja kroz dizajn hemijskog sastava i optimizaciju prinosa pirolize, što je posebno značajno zbog povećanog sadržaja kiseonika u proizvodima dobijenim pirolizom KS koji može povećati kiselost i korozivnu aktivnost bio-ulja.

Detalji članka

Broj časopisa

Rubrika

Ovaj rad je pod Creative Commons Autorstvo 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Kako citirati

Funding data

-

Bundesministerium für Bildung und Forschung

Grant numbers 01DS21008

Reference

[1] Ryu HW, Kim DH, Jae J, Lam SS, Park ED, Park Y-K. Recent advances in catalytic co-pyrolysis of biomass and plastic waste for the production of petroleum-like hydrocarbons. Bioresour Technol. 2020; 310: 123473. https://doi.org/10.1016/j.biortech.2020.123473

[2] Wang G, Dai Y, Yang H, Xiong Q, Wang K, Zhou J, Li Y, Wang S. A review of recent advances in biomasspyrolysis. Energ Fuel. 2020; 34(12): 15557-15578. https://doi.org/10.1021/acs.energyfuels.0c03107

[3] Chen H, Lin G, Chen Y, Chen W, Yang H. Biomass pyrolytic polygeneration of tobacco waste: product characteristics and nitrogen transformation. Energ Fuel. 2015; 30(3): 1579-1588. https://doi.org/10.1021/acs.energyfuels.5b02255.

[4] Munawer ME. Human health and environmental impacts of coal combustion and post-combustion wastes. J Sustain Min. 2018; 17(2): 87-96. https://doi.org/10.1016/j.jsm.2017.12.007.

[5] Martín JVG, González JF, Martínez G. Energetic use of the tomato plant waste. Fuel Process Technol. 2008; 89(11): 1193-1200. https://doi.org/10.1016/j.fuproc.2008.05.011.

[6] Tsai W, Lee MK, Chang Y-F. Fast pyrolysis of rice husk: Product yields and compositions. Bioresour Technol. 2007; 98(1): 22-28. https://doi.org/10.1016/j.biortech.2005.12.005 .

[7] Mohan D, Pittman ACU, Steele PH. Pyrolysis of Wood/Biomass for Bio-oil: A Critical review. Energ Fuel. 2006; 20(3): 848-889. https://doi.org/10.1021/ef0502397.

[8] Bridgwater AV. Renewable fuels and chemicals by thermal processing of biomass. J Chem Eng. 2003; 91(2-3): 87-102. https://doi.org/10.1016/s1385-8947(02)00142-0.

[9] Koul B, Yakoob MY, Shah MP. Agricultural waste management strategies for environmental sustainability. Environ Res. 2022; 206: 112285. https://doi.org/10.1016/j.envres.2021.112285.

[10] Maslac T. Grain and Feed Annual Report (Serbia). United States Department of Agriculture - Foreign Agricultural Service, 2021. https://apps.fas.usda.gov/newgainapi/api/Report/DownloadReportByFileName?fileName=Grain%20and%20Feed%20Annual_Belgrade_Serbia_04-01-2021

[11] Omais B, Crépier J, Charon N, Courtiade M, Quignard A, Thiébaut D. Oxygen speciation in upgraded fast pyrolysis bio-oils by comprehensive two-dimensional gas chromatography. Analyst 2013; 138(8): 2258. https://doi.org/10.1039/c2an35597c

[12] Ahmed I, Nipattummakul N, & Gupta A, Characteristics of syngas from co-gasification of polyethylene and woodchips. Appl Energy, 2010; 88(1): 165-174. https://doi.org/10.1016/j.apenergy.2010.07.007

[13] Wu M, Wang Z, Chen G, Zhang M, Sun T, Wang Q, Zhu H, Guo S, Chen Y, Zhu Y, Lei T, Burra K, G & Gupta AK, Synergistic effects and products distribution during Co-pyrolysis of biomass and plastics. J Energy Inst. 2023; 111, 101392. https://doi.org/10.1016/j.joei.2023.101392

[14] Liu X, Burra KG, Wang Z, Li J, Che D, & Gupta AK, On deconvolution for understanding synergistic effects in co-pyrolysis of pinewood and polypropylene. Appl Energy 2020; 279: 115811. https://doi.org/10.1016/j.apenergy.2020.115811

[15] Rutkowski P, Kubacki A. Influence of polystyrene addition to cellulose on chemical structure and properties of bio-oil obtained during pyrolysis. Energy Convers Manag. 2006; 47(6): 716-731. https://doi.org/10.1016/j.enconman.2005.05.017

[16] KositkanawuthK, Bhatt A, Sattler M, & Dennis, Renewable Energy from Waste: Investigation of Co-pyrolysis between Sargassum Macroalgae and Polystyrene. Energy Fuels. 2017; 31(5): 5088-5096. https://doi.org/10.1021/acs.energyfuels.6b03397

[17] Zheng Y, Tao L, Yang X, Huang Y, Liu C, Zheng Z. Study of the thermal behavior, kinetics, and product characterization of biomass and low-density polyethylene co-pyrolysis by thermogravimetric analysis and pyrolysis-GC/MS. J Anal Appl Pyrol. 2018; 133: 185-197. https://doi.org/10.1016/j.jaap.2018.04.001

[18] Jovancicevic I, Antić M, Gajica G, Schwarzbauer J. Co-pyrolysis of various plastic waste components as an environmentally sustainable source of alternative fuels. J Serb Chem Soc. 2024; 89(7-8): 1053-1066. https://doi.org/10.2298/jsc240207046j

[19] Wiley Registry/NIST Mass Spectral Library 2023. https://sciencesolutions.wiley.com/solutions/technique/gc-ms/wiley-registry-nist-mass-spectral-library/ (Accessed July 31, 2025)

[20] Pittman CU, Mohan D, Eseyin AE, Li Q, Ingram LL, Hassan EB, Mitchell B, Guo H, Steele PH. Characterization of Bio-oils Produced from Fast Pyrolysis of Corn Stalks in an Auger Reactor. Energ Fuel. 2012; 26(6): 3816-3825. https://doi.org/10.1021/ef3003922.

[21] Wang S, Lin X, Li Z, Yi W, Bai X. Thermal and kinetic behaviors of corn stover and polyethylene in catalytic co-pyrolysis. Bioresour. 2018; 13(2): 4102-4117. https://doi.org/10.15376/biores.13.2.4102-4117.

[22] Fan Y, Liu C, Kong X, Yue-Hong H, Lei M, Xiao R. A new perspective on polyethylene-promoted lignin pyrolysis with mass transfer and radical explanation. Green Energy Environ. 2022; 7(6): 1318-1326. https://doi.org/10.1016/j.gee.2021.02.004.

[23] Chu SY, Subrahmanyam AV, Huber GW. The pyrolysis chemistry of a β-O-4 type oligomeric lignin model compound. Green Chem. 2013; 15(1): 125-136. https://doi.org/10.1039/c2gc36332a.

[24] Chattopadhyay J, Pathak TS, Srivastava R, Singh A. Catalytic co-pyrolysis of paper biomass and plastic mixtures (HDPE (high density polyethylene), PP (polypropylene) and PET (polyethylene terephthalate)) and product analysis. Energy 2016; 103: 513-521. https://doi.org/10.1016/j.energy.2016.03.015.

[25] Nishu, Liu R, Rahman MdM, Sarker M, Chai M, Li C, Cai J. A review on the catalytic pyrolysis of biomass for the bio-oil production with ZSM-5: Focus on structure. Fuel Proc Technol. 2020; (199): 106301. https://doi.org/10.1016/j.fuproc.2019.106301

[26] Zadeh ZE, Abdulkhani A, Aboelazayem O, Saha B. Recent Insights into Lignocellulosic Biomass Pyrolysis: A Critical Review on Pretreatment, Characterization, and Products Upgrading. Processes. 2020; 8(7): 799. https://doi.org/10.3390/pr8070799