Prediction of functional characteristics of interlock and rib knitted fabrics by the use of 3D computational modelling and analysis Original scientific paper

Main Article Content

Abstract

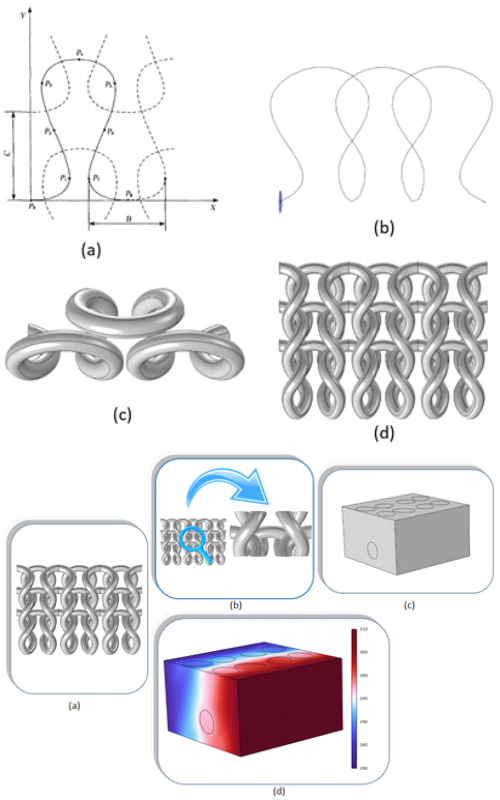

In this work, a computational model of interlock and rib knitted structures is developed to predict the air permeability and thermal properties of the fabric. Repeatable unit cells of interlock and rib structures are developed in COMSOL Multiphysics® software by using actual fabric parameters, extracted with the help of an image analysis technique. The obtained modeling results are then compared with the actual experimental values for the fabric. Furthermore, the validated computational model is utilized to analyze the effect of stitch length and fabric thickness on the thermal properties and air permeability of the fabric. It is found that stitch length has a direct relation with air permeability and an inverse relation with effective thermal conductivity. The fabric thickness influences directly the effective thermal conductivity and has an inverse relation with air permeability of the fabric.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Higher Education Commision, Pakistan

Grant numbers GCF-63 WP#04

References

[1] Li YL, Chen SY, Yang LH, Cao LH. Study on three-dimension computer simulation of plain knitted fabrics. Adv Mat Res. 2011; 213: 595–599 https://doi.org/10.4028/www.scientific.net/AMR.213.595

[2] Sha S, Geng A, Gao Y, Li B, Jiang X, Tao H, Luo L, Yuan X, Ke H, Hu X. Review on the 3D simulation for weft knitted fabric. J Eng Fiber Fabr. 2021; 16: 1-10 https://doi.org/10.1177/15589250211012527

[3] Peirce FT. Geometrical principles applicable to the design of functional fabrics. Text Res J. 1947; 17(3): 123-147. https://doi.org/10.1177/004051754701700301

[4] Hurd JCH, Doyle, PJ. Fundamental aspects of the design of knitted fabrics. J Text Inst Proc. 1953; 44(8): 561-578. https://doi.org/10.1080/19447015308687861

[5] Shinn WE. An engineering approach to jersey fabric construction. Text Res J. 1953; 25(3): 270-277. https://doi.org/10.1177/004051755502500314

[6] Leaf GAV, Glaskin A. 43—The geometry of a plain knitted loop. J Text Inst Trans. 1955; 46(9): T587-T605. https://doi.org/10.1080/19447027.1955.10750345

[7] Munden D L. 26—The geometry and dimensional properties of plain-knit fabrics. J Text Inst Trans. 1959; 50(7): T448-T471. https://doi.org/10.1080/19447025908659923

[8] Postle R. 6—Dimensional stability of plain-knitted fabrics. J Text Inst. 1968; 59(2): 65-77. https://doi.org/10.1080/00405006808659967

[9] Kurbak A. Plain knitted fabric dimensions (Part II). Text A. 1998; 78: 36-44.

[10] Demiroz A, Dias T. A study of the graphical representation of plain-knitted structures part I: Stitch model for the graphical representation of plain-knitted structures. J Text Inst. 2000; 91(4): 463-480. https://doi.org/10.1080/00405000008659121

[11] Choi KF, Lo TY, An energy model of plain knitted fabric. Text Res J. 2003; 73(8): 739-748. https://doi.org/10.1177/004051750307300813

[12] Kyosev Y, Angelova Y and Kovar R. 3D modeling of plain weft knitted structures of compressible yarn. Res J Text Appar. 2005; 9(1): 88-97. https://doi.org/10.1108/RJTA-09-01-2005-B009

[13] Delavari K, Dabiryan H. Mathematical and numerical simulation of geometry and mechanical behavior of sandwich composites reinforced with 1× 1-Rib-Gaiting weft-knitted spacer fabric; compressional behavior. Compos Struct. 2021; 268: 113952. https://doi.org/10.1016/j.compstruct.2021.113952

[14] Ghatrenabi MH, Dabiryan H, Nosraty H. Modeling the Geometry of Weft-knitted Integrated Preforms as Reinforcement of Composite Joints. Fibers Polym. 2021; 22(9): 2572-2580. https://doi.org/10.1007/s12221-021-1180-x

[15] Omrani E, Dibajian SH, Hasani H. Development of ABAQUS Plugin Predicting the Mechanical Behavior and Failure Modes of Weft knitted-Reinforced Composites. Fibers Polym. 2025; 26: 883-907. http://dx.doi.org/10.1007/s12221-025-00850-2

[16] Huang R. Characterization and Modeling of Pores in Weft-Knitted Fabrics. PhD Dissertation, North Carolina State University; 2023. https://www.lib.ncsu.edu/resolver/1840.20/40816

[17] Ogulata RT. Air permeability of woven fabrics. J Text Appar Tech and Manag. 2006; 5(2): 1–10. https://www.researchgate.net/publication/283451342_Air_Permeability_of_Woven_Fabrics

[18] Jeddi AAA, Dabiryan H. Ideal stitch model for interlock-knitted fabric. J Text Inst. 2008; 99(4): 369–374. https://doi.org/10.1080/00405000701584444

[19] Li Y L, Yang L H, Chen S Y, Yuan J, Li N-N. 3D modeling and simulation of fancy fabrics in weft knitting. J DongHua Uni. 2012; 29(4): 351-358. https://doi.org/10.19884/j.1672-5220.2012.04.013

[20] Kejkar VKV, Tjprc. An Effect of Stitch Length. Lycra Percentage on Comfort Properties of Knitted Sport Wear. Int J Text Fash Tech. 2019; 9(3): 1-10. https://paper.researchbib.com/view/paper/225864

[21] Chakroun M G, Benltoufa S, Fayala F. The effect of fabric’s structure on the breathability and the drying rate properties. Comm Develop Assem Text Prod. 2021; 2(1): 61–69. https://doi.org/10.25367/cdatp.2021.2.p61-69

[22] Megeid ZMA, Al-Bakry M, Ezzat M. The influence of stitch length of weft knitted fabrics on the sewability. J Amer Sci. 2011; 7(8): 610–617. https://www.jofamericanscience.org/journals/am-sci/am0708/068_6200am0708_610_617.pdf

[23] Gebart BR. Permeability of unidirectional reinforcements for RTM. J Compos Mater 1992; 26(8): 1100–1133. https://doi.org/10.1177/002199839202600802

[24] Afzal A, Ahmad S, Rasheed A, Ahmad F, Iftikhar F, Nawab Y. Influence of fabric parameters on thermal comfort performance of double layer knitted interlock fabrics. Autex Res J. 2017; 17(1): 20–26. https://doi.org/10.1515/aut-2015-0037

[25] Kaviany M. Principles of Heat Transfer in Porous Media. 2nd ed., Springer, New York, USA; 1995. https://doi.org/10.1016/S0017-9310(05)80083-3