Microstructure, hardness and fracture resistance of P235TR1 seam steel pipes of different diameters Original scientific paper

Main Article Content

Abstract

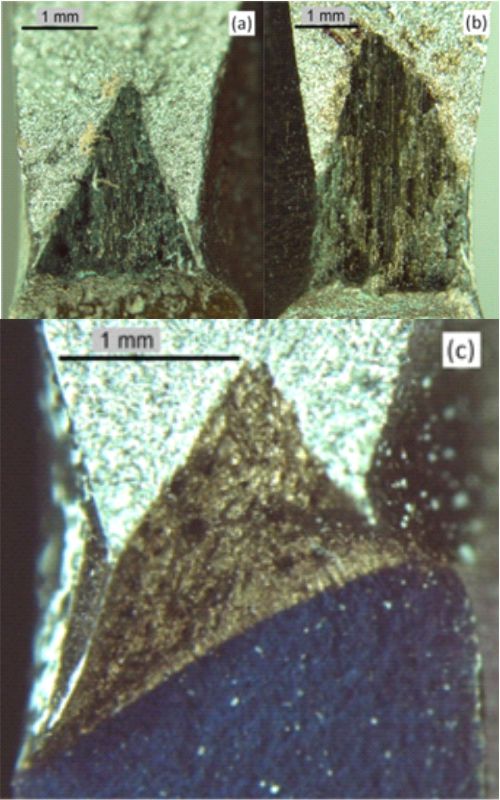

Steel pipelines in industrial plants consist of different elements, including seamless and/or welded (seam) pipes. Properties of welded pipes, including their fracture behaviour, depend on the characteristics of both, the base metal, and the weld metal. In this work, two seam pipes are considered having different diameters and manufactured of P235TR1 steel. Hardness and microstructure were examined on the samples which contained the seam zone, to capture the influence of heterogeneity. Fracture resistance of the pipeline material, i.e. of both base metals and both seams, was determined by experimental examination of the recently proposed Pipe ring notch bending specimens with sharp stress concentrators. Differences between the two tested pipes, including the influence of the heterogeneity caused by the welded joint, were determined by comparison of the crack growth resistance curves. Effects of the initial stress concentrator shape, sharp machined notch or fatigue pre-crack are discussed.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/200135

References

Moattari M, Moshayedi H, Sattari-Far I. Application of new constraint based Master Curve in fracture assessment of pressure vessels. Int J Pres Ves Pip. 2019; 174: 25–31. https://doi.org/10.1016/j.ijpvp.2019.05.009

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Veg E. Welded joints as critical regions in pressure vessels - case study of vinyl chloride monomer storage tank. Hem Ind. 2018; 72: 177–182. https://doi.org/10.2298/HEMIND171009006G

Murtaza UT, Javed Hyder M. Fracture analysis of the set-in nozzle of a PWR reactor pressure vessel - Part 1: Determination of critical crack. Eng Fract Mech. 2018; 192: 343–361. https://doi.org/10.1016/j.engfracmech.2016.03.049

Mitrović N, Petrović A, Milošević M, Momčilović N, Mišković Ž, Maneski T, Popović P. Experimental and numerical study of globe valve housing. Hem Ind. 2017; 71: 251–257. https://doi.org/10.2298/HEMIND160516035M

Šarkoćević Ž, Rakin M, Arsić M, Sedmak A. Fabrication of high strength seam welded steel tubes and quality indicator testing. Struct Integr Life. 2008; 8: 81–98. http://divk.inovacionicentar.rs/ivk/ivk08/ivk0802-1.html

Choupani N, Asghari V, Kurtaran, H. Fracture Characterization of Base Metal, Seam Weld, and Girth Weld of Welded Line Pipe Steel at Room and Low Temperatures. J Mater Eng Perf. 2021; 30: 1046–1053. https://dx.doi.org/10.1007/s11665-020-05431-3

Angeles-Herrera D, Albiter-Hernández A, Cuamatzi-Meléndez R, González-Velázquez JL. Fracture toughness in the circumferential-longitudinal and circumferential-radial directions of longitudinal weld API 5L X52 pipeline using standard C(T) and nonstandard curved SE(B) specimens. Int J Fract. 2014; 188: 251–256. https://dx.doi.org/10.1007/s10704-014-9949-1

Chen Z, Chen X, Zhou T. Microstructure and Mechanical Properties of J55ERW Steel Pipe Processed by On-Line Spray Water Cooling. Metals. 2017; 7: paper No. 150. https://doi.org/10.3390/met7040150

Van Minnebruggen K, Hertelé S, Thibaux P, De Waele W. Effects of specimen geometry and anisotropic material response on the tensile strain capacity of flawed spiral welded pipes. Eng Fract Mech. 2015; 148: 350–362. https://doi.org/10.1016/j.engfracmech.2015.04.031

Gajdos L, Sperl M. Evaluating the integrity of pressure pipelines by fracture mechanics. In: Applied Fracture Mechanics, London: InTech Publishing; 2012: 283–310. https://dx.doi.org/10.5772/51804

Zhang ZL, Xu J, Nyhus B, Østby E. SENT (single edge notch tension) methodology for pipeline applications. In: Proceedings of the 18th European Conference on Fracture, Dresden, Germany, 2010, pp. 1-8, published on CD.

Xu J, Zhang ZL, Østby E, Nyhus B, Sun DB. Effects of crack depth and specimen size on ductile crack growth of SENT and SENB specimens for fracture mechanics evaluation of pipeline steels. Int J Pres Ves Pip. 2009; 86: 787–797. https://dx.doi.org/10.1016/j.ijpvp.2009.12.004

Xu J, Zhang ZL, Østby E, Nyhus B, Sun DB. Constraint effect on the ductile crack growth resistance of circumferentially cracked pipes. Eng Fract Mech. 2010; 77: 671–684. https://dx.doi.org/10.1016/j.engfracmech.2009.11.005

Mahajan G, Saxena S, Mohanty A. Numerical characterization of compact pipe specimen for stretch zone width assessment. Fatigue Fract Engng Mater Struct. 2016; 39: 859–865. https://dx.doi.org/10.1111/ffe.12400

Koo JM, Park S, Seok CS. Evaluation of fracture toughness of nuclear piping using real pipe and tensile compact pipe specimens. Nucl Eng Design. 2013; 259: 198–204. https://dx.doi.org/10.1016/j.nucengdes.2013.03.001

Bergant M, Yawny A, Perez Ipiña J. Experimental determination of J-resistance curves of nuclear steam generator tubes. Eng Fract Mech. 2016; 164: 1–18. https://dx.doi.org/10.1016/j.engfracmech.2016.07.008

Bergant M, Yawny A, Perez Ipiña J. Numerical study of the applicability of the g-factor method to J-resistance curve determination of steam generator tubes using non-standard specimens. Eng Fract Mech. 2015; 146: 109–120. https://dx.doi.org/10.1016/j.engfracmech.2015.07.059

Capelle J, Pluvinage G, Modification of failure risk by the use of high strength steels in pipelines, Struct Integr Life. 2013: 13; 23–27 http://divk.inovacionicentar.rs/ivk/ivk13/ivk1301-4.html

Matvienko YG, Gubeljak N. Model for Determination of crack-resistance of the pipes. Patent No. RU 2564696 C, 2015 (in Russian)

Gubeljak N, Likeb A, Matvienko Y. Fracture toughness measurement by using pipe-ring specimens. Proc Mater Sci. 2014; 3: 1934–1940. https://dx.doi.org/10.1016/j.mspro.2014.06.312

Likeb A. Suitability of pipe-ring specimen for determination of fracture toughness. PhD Thesis, University of Maribor, Faculty of Mechanical Engineering, Slovenia, 2014 (in Slovenian)

Likeb A, Gubeljak N, Matvienko Y. Finite element estimation of the plastic ηpl factors for pipe-ring notched bend specimen using the load separation method. Fatigue Fract Eng Mater Struct. 2014; 37: 1319–1329. https://dx.doi.org/10.1111/ffe.12173

Musraty W, Medjo B, Gubeljak N, Likeb A, Cvijović-Alagić I, Sedmak A, Rakin M. Ductile fracture of pipe-ring notched bend specimens - micromechanical analysis. Eng Fract Mech. 2017; 175: 247–261. https://dx.doi.org/10.1016/j.engfracmech.2017.01.022

Damjanović D, Kozak D, Gubeljak N. The influence of residual stresses on fracture behavior of Pipe Ring Notched Bend specimen (PRNB), Eng Fract Mech. 2019; 205: 347–358. https://dx.doi.org/10.1016/j.engfracmech.2018.10.016

Musrati W, Međo B, Gubeljak N, Štefane P, Veljić D, Sedmak A, Rakin M. Fracture assessment of seam and seamless steel pipes by application of the ring-shaped bending specimens. Theor Appl Fract Mech. 2019; 103: paper No. 102302. https://dx.doi.org/10.1016/j.tafmec.2019.102302

Musraty W., Međo B., Gubeljak N., Štefane P., Radosavljević Z., Burzić Z., Rakin M. Seam pipes for process industry - fracture analysis by using ring-shaped specimens. Hem Ind. 2018; 72: 39–46. https://dx.doi.org/10.2298/HEMIND170530014M

EN 10217-1: Welded steel tubes for pressure purposes. Technical delivery conditions Electric welded and submerged arc welded non-alloy steel tubes with specified room temperature properties, 2019.

Inspection certificates No. 31042 and No. 33131/1, Arcelor Mittal Tubular Products Iasi S.A., Romania, 2015.

GOM Precise Industrial 3D Metrology. www.gom.com. Accessed in January, 2023.

Gubeljak N. Application of stereometric measurement on structural integrity. Struct Integr Life. 2006; 6: 65–74. http://divk.inovacionicentar.rs/ivk/ivk06/ivk0601-7.html

Musrati W. Characterisation of damage and fracture of pipeline material using ring-shaped specimens. PhD Thesis, University of Belgrade, Faculty of Technology and Metallurgy, Serbia, 2019.

ASTM E1820: Standard test method for measurement of fracture toughness. 2015.

Displacement gauge system for applications in fracture mechanics. Patent Publication, GKSS Research Center, Geesthacht, Germany, 1991.