Water vapour permeability of nylon pantyhose Original scientific paper

Main Article Content

Abstract

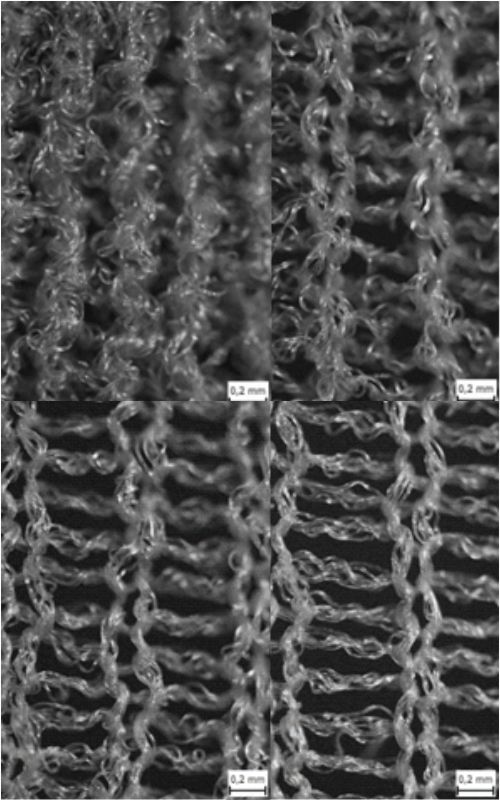

Comfort properties of clothing are one of the main indicators of clothing quality and have been widely investigated in the past decades. This research concentrates on the water vapour permeability of nylon pantyhose, by examining behaviours in the relaxed state, as well as under extension of knits of 100 %, comparative to wear conditions and above 100 %. Permetest apparatus was used to measure the water vapour permeability according to the standard ISO 11092. The results indicate that for very fine fabrics permeability stays constant under extension, while for fabrics above 44 dtex the water vapour permeability changes significantly with extension.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

Funding data

-

International Visegrad Fund

Grant numbers 2017

References

Sweeney MM, Branson DH. Sensorial Comfort. Part I: A Psychophysical Method for Assessing Moisture Sensation in Clothing. Text Res J. 1990; 60(7): 371-377. https://doi.org/10.1177/004051759006000701 .

Hes L, de Araujo M. Simulation of the Effect of Air Gaps between the Skin and a Wet Fabric on Resulting Cooling Flow. Text Res J. 2010; 80(14): 1488–1497. https://doi.org/10.1177/0040517510361797.

Bertaux E, Derler S, Rossi R M, Xianyi Z, Koehl L, Ventenat V. Textile, Physiological, and Sensorial Parameters in Sock Comfort. Text Res J. 2010; 80(17): 1803–1810. https://doi.org/10.1177/0040517510369409.

Das B, Das A, Kothari VK, Fanguiero R, de Araújo M. Moisture Transmission Through Textiles Part I: Processes involved in moisture transmission and the factors at play. Autex Res J. 2007; 7(2): 100-110. http://www.autexrj.org/No3-2007/0236.pdf.

Das B, Das A, Kothari VK, Fanguiero R, de Araújo M. Moisture Transmission Through Textiles Part II: Evaluation Methods and Mathematical Modellin. Autex Res. J. 2007; 7(3): 194-216. http://www.autexrj.org/No3-2007/0236.pdf.

Parsons KC.Human thermal environments, Taylor & Francis Publishers, United Kingdom, 1993 https://doi.org/10.1201/b16750.

Sampath MB, Senthilkumar M, Nalankilli G. Effect of filament fineness on comfort characteristics of moisture management finished polyester knitted fabrics. J Ind Tex., 2011; 41(2): 160–173. https://doi.org/10.1177/1528083711400774.

Gericke A, Van der Pol J. A comparative study of regenerated bamboo, cotton and viscose rayon fabrics. Part 1: selected comfort properties. J Fam Ecol Cons Sci. 2010; 38: 63–73. https://www.ajol.info/index.php/jfecs/article/view/61642.

Amber RRV, Wilson CA, Laing RM, Lowe BJ, Niven BE. Thermal and moisture transfer properties of sock fabrics differing in fiber type, yarn, and fabric structure. Text Res J. 2015; 85(12):1269 -1280. https://doi.org/10.1177/0040517514561926.

Bogusławska-Bączek M, Hes L. Effective Water Vapour Permeability of Wet Wool Fabric and Blended Fabrics. Fibres Text East Eur. 2013; 21(1): 67-71. http://www.fibtex.lodz.pl/article844.html.

Ucar N, Yilmaz T. Thermal properties of 1_1, 2_2,3_3 rib knit fabrics. Fibres Text East Eur. 2004; 12(3): 34–38. http://www.fibtex.lodz.pl/archive.htm.

Erdumlu N, Saricam C. Investigating the effect of some fabric parameters on the thermal comfort properties of flat knitted acrylic fabrics for winter wear. Text Res J. 2017; 87(11): 1349–1359. https://doi.org/10.1177/0040517516652347.

Mansoor T, Hes L, Skenderi Z, Siddique H, Hussain H, Javed A. Effect of preheat setting process on heat, mass and air transfer in plain socks. J Text Ins. 2019; 110(2): 159-170. https://doi.org/10.1080/00405000.2018.1523990.

] Mansoor T, Hes L, Bajzik V, Noman M T. Novel method on thermal resistance prediction and thermo-physiological comfort of socks in a wet state. Text Res J. 2020; 90(17-18): 1987-2006. https://doi.org/10.1177/0040517520902540.

Loginov U, Grishanov SA, Harwood RJ. Modelling the Load–Extension Behaviour of Plain-knitted Fabric: Part I: A Unit-cell Approach towards Knitted-fabric Mechanics. J Text Ins. 2002; 93(3): 218-238. https://doi.org/10.1080/00405000208630566.

Popper P. The Theoretical Behavior of a Knitted Fabric Subjected to Biaxial Stresses. Text Res J. 1966; 36(2): 148 https://doi.org/10.1177/004051756603600208.

Karimi HR, Jeddi AAA, Rastgoo A. Theoretical analysis of load–extension behaviour of plain-weft-knitted fabric, J Text Ins. 2009; 100(1): 18-27. https://doi.org/10.1080/00405000701692544.

Shanahan W J, Postle R. Jamming of Knitted Structures. Text Res J. 1973; 43(9): 532–538. https://doi.org/10.1177/004051757304300907.

Ziaei M, Ghane M, Hasani H, Saboonchi A. Simulation of Temperature Distribution Within Weft-Knitted Fabrics in Extended State. Cloth Tex Res J. 2019; 37(4): 297-312. https://doi.org/10.1177/0887302X19856112.

Khalil A, Fouda A, Těšinová P, Eldeeb AS. Comprehensive Assessment of the Properties of Cotton Single Jersey Knitted Fabrics Produced from Different Lycra States. Autex Res J. 2021; 21(1): 71-78. https://doi.org/10.2478/aut-2020-0020.

Tomovska E, Hes L. Thermophysiological Comfort Properties of Polyamide Pantyhose. Fibres Text East Eur. 2019; 27(5): 53-58. https://doi.org/10.5604/01.3001.0013.2902.