Predviđanje termičkih i mehaničkih svojstava kompozita na bazi akrilata korišćenjem modela veštačke neuronske mreže Naučni rad

Glavni sadržaj članka

Apstrakt

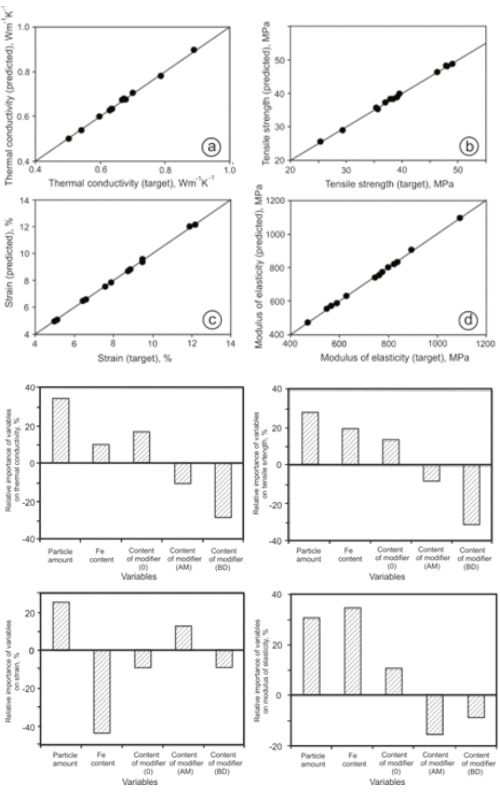

Poli (metil metakrilata) (PMMA) ima široku upotrebu, posebno u stomatologiji i medicini. Kompoziti su napravljeni od PMMA modifikovanog dimetil itakonatom (DMI) kao matrice. Kao pojačanje korišćene su čestice glinice (Al2O3) i glinice dopirane oksidom gvožđa (Al2O3-Fe) modifikovanim sa 3-aminopropil-trimetoksilanom (AM) i metil estrima masnih kiselina lanenog ulja (biodizel – BD). Prema merenjima toplotne provodljivosti, najveće vrednosti toplotne provodljivosti imao je kompozit sa česticama glinice 5 wt.% Al2O3-Fe-AM. Dodatkom modifikovanih čestica glinice u PMMA/DMI matricu, poboljšane su mehaničke osobine (zatezna čvrstoća, deformacija i modul elastičnosti). Razvijen je model veštačke neuronske mreže zasnovan na iterativnom algoritmu predloženom u literaturi (Broiden-Fletcher-Goldfarb-Shanno), za predviđanje toplotne provodljivosti i mehaničkih svojstava kompozita na bazi akrilata u kombinaciji sa česticama na bazi glinice, u zavisnosti od masenog udela čestica, i dodatka oksida gvožđa i modifikatora. Pokazano je da ovi matematički modeli mogu predvideti mehanička i termička svojstva kompozitnih materijala. Ovo je posebno relevantno za predviđanje toplotne provodljivosti materijala koji se koriste u stomatologiji za izradu proteza i koji su izloženi temperaturnim promenama tokom primene

Downloads

Detalji članka

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-47/2023-01/20023

Reference

Kurtz SM, Villarraga ML, Zhao K, Edidin AA. Static and fatigue mechanical behavior of bone cement with elevated barium sulfate content for treatment of vertebral compression fractures. Biomaterials. 2005; 26: 3699-3712. https://doi.org/10.1016/j.biomaterials.2004.09.055

Pascual B, Vtiquez B, Gurruchaga M, Goti I, Ginebra MP, Gil FJ, Planell JA, Levenfeld B, San Romans J. New Aspects of the Effect of Size and Size Distribution on the Setting Parameters and Mechanical Properties of Acrylic Bone Cements. Biomaterials. 1996; 17: 509-516. https://doi.org/10.1016/0142-9612(96)82725-6

Serbetci K, Korkusuz F, Hasirci N. Thermal and Mechanical Properties of Hydroxyapatite Impregnated acrylic bone cements. Polym Test. 2004; 23: 145-155. https://doi.org/10.1016/S0142-9418(03)00073-4

Provenzano MJ, Murphy KPJ, Riley LH. Bone Cements: review of their physiochemical and biochemical properties in percutaneous vertebroplasty. AJNR Am J Neuroradiol. 2004; 25: 1286-1290. http://www.ajnr.org/content/25/7/1286.short

Haas SS, Brauer GM, Dickson GA. Characterization of Poly Methyl Methacrylate Bone Cement. J Bone Joint Surg Am. 1957; 57: 380-391. https://pubmed.ncbi.nlm.nih.gov/1123392/

Postawa P, Szarek A, Koszkul J. DMTA method in determining strength parameters of acrylic cements. Arch Mater Sci Eng. 2007; 28: 309-312. http://www.amse.acmsse.h2.pl/vol28_5/28512.pdf

Khaled SMZ, Charpentier PA, Rizkalla AS. Physical and mechanical properties of PMMA bone cement reinforced with nano-sized titania fibers. J Biomater Appl. 2011; 25: 515-537. https://doi.org/10.1177/0885328209356944

Fernández-Garcia M, Fuente JL, Madruga EL, Thermal behavior of poly(dimethyl itaconate) and poly(di-n-butyl itaconate) copolymerized with methyl methacrylate. Polym Eng Sci. 2001; 41: 1616-1625. https://doi.org/10.1002/pen.10859

EN ISO 20795-1:2013 Dentistry - Base polymers- Part 1: Denture base polymers (ISO 20795-1:2013).

Spasojević P, Stamenković D, Pjanović R, Bošković Vragolović N, Dolić J, Grujić S, Veličković S. Diffusion and solubility of commercial poly(methyl methacrylate) denture base material modified with dimethyl itaconate and di-n-butyl itaconate during water absorption/desorption cycles. Polym Int. 2012; 61: 1272-1278. https://doi.org/10.1002/pi.4202

Alzarrug FA, Dimitrijević MM, Jančić Heinemann RM, Radojević V, Stojanović DB, Uskoković PS, Aleksić R. The use of different alumina fillers for improvement of the mechanical properties of hybrid PMMA composites. Mater Des. 2015; 86: 575-581. https://doi.org/10.1016/j.matdes.2015.07.069

Fu SY, Feng XQ, Lauke B, Mai YW. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos B Eng. 2008; 39: 933-961. https://doi.org/10.1016/j.compositesb.2008.01.002

Johnsen BB, Fromyr TR, Thorvaldsen T, Olsen T. Preparation and characterization of epoxy/alumina polymer nanocomposites. Compos Interfaces. 2013; 20: 721-740. https://doi.org/10.1080/15685543.2013.815603

Lazouzi GA, Vuksanović MM, Tomić NZ, Mitrić M, Petrović M, Radojević V, Heinemann RJ. Optimized preparation of alumina based fillers for tuning composite properties. Ceram Int. 2018; 44: 7442-7449. https://doi.org/10.1016/j.ceramint.2018.01.083

Mathieu A, Matteï S, Deschamps A, Martin B, Grevey D. Temperature control in laser brazing of a steel/aluminium assembly using thermographic measurements. NDT E Int. 2006; 39: 272-276. https://doi.org/10.1016/j.ndteint.2005.08.005

Ma J, Wu B. Effect of surfactants on preparation of nanoscale-Al2O3 powders by oil-inwater micro emulsion. Adv Powder Technol. 2013; 24: 354-358. https://doi.org/10.1016/j.apt.2012.08.008

Mališić V, Tomić N, Vuksanović M, Balač B, Stević Z, Marinković A, Jančić-Heinemann R, Putić S. An Experimental study of mechanical properties and heat transfer of acrylic composites with structural and surface modified Al2O3 particles. Sci Sinter. 2020; 52: 457-467. https://doi.org/10.2298/SOS2004457M

Rizzo P, Scalea FL. Acoustic emission monitoring of carbon-fiber-reinforced polymerbridge stay cables in large-scale testing. Exp Mech. 2001; 41: 282-290. https://doi.org/10.1007/BF02323146

Johnson DP, Stanforth A, Lulla V, Luber G. Developing an applied extreme heat vulnerability index utilizing socioeconomic and environmental data. Appl Geogr. 2012; 35: 23-31. https://doi.org/10.1016/j.apgeog.2012.04.006

Yun TS, Jeong YJ, Han TS, Youm KS. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013; 61: 125-132. https://doi.org/10.1016/j.enbuild.2013.01.043

Kleijnen JPC. Design and Analysis of Simulation Experiments. Springer, US, 2018; 111-121. https://doi.org/10.1007/978-3-319-76035-3_1

Pavlić B, Pezo L, Marić B, Peić Tukuljac L, Zeković Z, Bodroža Solarov M, Teslić N. Supercritical fluid extraction of raspberry seed oil: Experiments and modelling. J Supercrit Fluids. 2020; 157: 104687. https://doi.org/10.1016/j.supflu.2019.104687

Kollo T, Rosen D. Advanced Multivariate Statistics with Matrices. Springer, Dordrecht, 2005. 98-125. https://link.springer.com/book/10.1007/1-4020-3419-9

Pezo L, Ćurčić BLj, Filipović VS, Nićetin MR, Koprivica GB, Mišljenović NM, Lević LjB. Artificial neural network model of pork meat cubes osmotic dehydratation. Hem Ind. 2013; 67: 465-475. https://doi.org/10.2298/HEMIND120529082P

Ochoa-Martínez CI, Ayala-Aponte AA. Prediction of mass transfer kinetics during osmotic dehydration of apples using neural networks. LWT - Food Sci Technol. 2007; 40: 638-645. https://doi.org/10.1016/j.lwt.2006.03.013

Berrueta LA, Alonso-Salces RM, Héberger K. Supervised pattern recognition in food analysis. J Chromatogr. 2007; 1158: 196-214. https://doi.org/10.1016/j.chroma.2007.05.024

Doumpos M, Zopounidis C. Preference disaggregation and statistical learning for multicriteria decision support: A review. Eur J Oper Res. 2011; 209: 203-214. https://doi.org/10.1016/j.ejor.2010.05.029

Taylo BJ. Methods and Procedures for the Verification and Validation of Artificial Neural Networks. Springer Science & Business Media, New York, 2006; 51-67. https://doi.org/10.1007/0-387-29485-6

Yoon Y, Swales G , Margavio TM. A Comparison of Discriminant Analysis versus Artificial Neural Networks. J Oper Res Soc. 1993; 44: 51-60. https://doi.org/10.2307/2584434

Aćimović M, Pezo L, Tešević V, Čabarkapa I, Todosijević M. QSRR Model for predicting retention indices of Satureja kitaibelii Wierzb. ex Heuff. essential oil composition. Ind Crops Prod. 2020; 154: 112752. https://doi.org/10.1016/j.indcrop.2020.112752

Dos Santos WN, De Sousa JA, Gregorio R. Thermal conductivity behaviour of polymers around glass transition and crystalline melting temperatures. Polym Test. 2013; 32: 987-994. https://doi.org/10.1016/j.polymertesting.2013.05.007

Friederich B, Laachachi A, Ferriol M, Ruch D, Cochez M, Toniazzo V. Tentative links between thermal diffusivity and fire-retardant properties in poly(methyl methacrylate)-metal oxide nanocomposites. Polym Degrad Stab. 2010; 95: 1183-1193. https://doi.org/10.1016/j.polymdegradstab.2010.04.008

Patel T, Suin S, Bhattacharya D, Khatua BB. Transparent and Thermally Conductive Polycarbonate (PC)/Alumina (Al2O3) Nanocomposites: Preparation and Characterizations. Polym Plast Technol Eng. 2013; 52: 1557-1565. https://doi.org/10.1080/03602559.2013.824464

Lazouzi GA, Vuksanović MM, Tomić N, Petrović M, Spasojević P, Radojević V, Jančić R H. Dimethyl Itaconate Modified PMMA ‐ Alumina Fillers Composites With Improved Mechanical Properties. Polym Compos. 2019; 40: 1691-1701. https://doi.org/10.1002/pc.24952

Montgomery DC. Design and Analysis of Experiments.Wiley, 2012; ISBN 9781118146927

Chattopadhyay PB, Rangarajan R. Application of ANN in sketching spatial nonlinearity of unconfined aquifer in agricultural basin. Agric Water Manag. 2014; 133: 81-91. https://doi.org/10.1016/j.agwat.2013.11.007

Erbay Z, Icier F. Optimization of hot air drying of olive leaves using response surface methodology. J Food Eng. 2009; 91: 533-541 https://doi.org/10.1016/j.jfoodeng.2008.10.004