Numerička simulacija implanta kuka od titan legure pod statičkim i dinamičkim opterećenjima Original scientific paper

Glavni sadržaj članka

Apstrakt

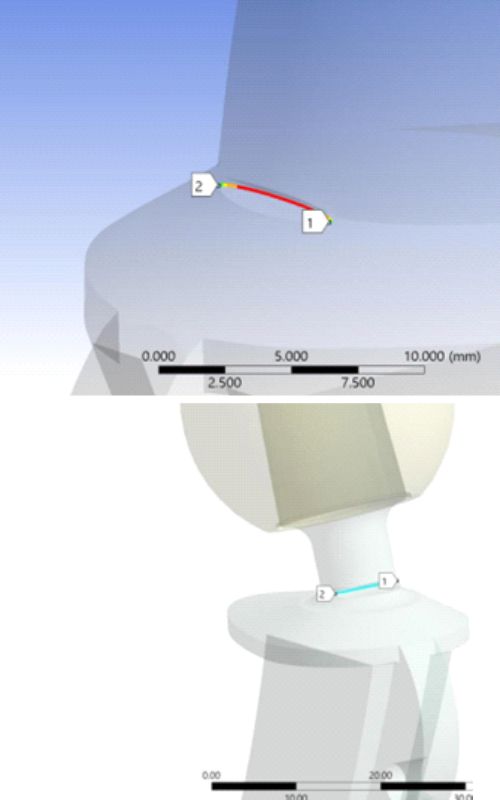

U ovom radu je prikazan razvoj numeričkih modela za simulaciju implanta za zamenu zgloba kuka pod statičkim i dinamičkim opterećenjima, kao deo širokog istraživanja koje uključuje procenu integriteta implanata kuka u različitim uslovima, kao što su zamor i korozija. Numerički modeli su napravljeni u ABAQUS i ANSYS softverskim paketima, u cilju procene distribucije napon/deformacija i broja ciklusa do loma, kao i vrednosti faktora intenziteta napona za dve različite geometrije implanta kuka. ABAQUS modeli su korišćeni za simulaciju pod statičkim, a ANSYS modeli za simulaciju pod dinamičkim opterećenjima. Sledeća etapa analize uključuje poređenje ova dva slučaja, kako bi se odredilo koja od ove dve geometrije pruža bolje ponašanje u eksploatacionim uslovima, a koje mogu značajno varirati zavisno od pacijenta. Simulacije su vršene za pacijenta mase 90 kg. Za ovu svrhu, dijagrami procene rizika su napravljeni za obe navedene geometrije, pod pretpostavkom da je dužina inicijalne prsline 1 mm.

Downloads

Detalji članka

Ovaj rad je pod Creative Commons Aуторство-Nekomercijalno-Bez prerade 4.0 Internacionalna licenca.

Kada je rukopis prihvaćen za objavlјivanje, autori prenose autorska prava na izdavača. U slučaju da rukopis ne bude prihvaćen za štampu u časopisu, autori zadržavaju sva prava.

Na izdavača se prenose sledeća prava na rukopis, uklјučujući i dodatne materijale, i sve delove, izvode ili elemente rukopisa:

- pravo da reprodukuje i distribuira rukopis u štampanom obliku, uklјučujući i štampanje na zahtev;

- pravo na štampanje probnih primeraka, reprint i specijalnih izdanja rukopisa;

- pravo da rukopis prevede na druge jezike;

- pravo da rukopis reprodukuje koristeći fotomehanička ili slična sredstva, uklјučujući, ali ne ograničavajući se na fotokopiranje, i pravo da distribuira ove kopije;

- pravo da rukopis reprodukuje i distribuira elektronski ili optički koristeći sve nosioce podataka ili medija za pohranjivanje, a naročito u mašinski čitlјivoj/digitalizovanoj formi na nosačima podataka kao što su hard disk, CD-ROM, DVD, Blu-ray Disc (BD), mini disk, trake sa podacima, i pravo da reprodukuje i distribuira rukopis sa tih prenosnika podataka;

- pravo da sačuva rukopis u bazama podataka, uklјučujući i onlajn baze podataka, kao i pravo prenosa rukopisa u svim tehničkim sistemima i režimima;

- pravo da rukopis učini dostupnim javnosti ili zatvorenim grupama korisnika na osnovu pojedinačnih zahteva za upotrebu na monitoru ili drugim čitačima (uklјučujući i čitače elektonskih knjiga), i u štampanoj formi za korisnike, bilo putem interneta, onlajn servisa, ili putem internih ili eksternih mreža.

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200105;451-03-68/2022-14/200135

Reference

Sarraf M, Ghomi ER, Alipour S, Ramakrishna S, Sukiman NL. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-des. Manuf. 2022; 5: 371-395. https://doi.org/10.1007/s42242-021-00170-3.

Kirmanidou Y, Sidira M, Drosou ME, Bennani V, Bakopoulou A, Tsouknidas A, Michailidis N, Michalakis K. New Ti-Alloys and Surface Modifications to Improve the Mechanical Properties and the Biological Response to Orthopedic and Dental Implants: A Review. BioMed Res Inter. 2016; 2908570. https://doi.org/10.1155/2016/2908570.

Eisenbarth E, Velten D, Muller M, Thull R, Breme J. Biocompatibility of beta-stabilizing elements of titanium alloys. Biomaterials 2004; 25(26): 5705-5713. https://doi.org/ 10.1016/j.biomaterials.2004.01.021.

Niinomi M, Nakai M, Hieda J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012; 8(11): 3888-3903. https://doi.org/ 10.1016/j.actbio.2012.06.037.

Sedmak A, Čolić K, Burzić Z, Tadić S. Structural integrity assessment of hip implant made of cobalt-chromium multiphase alloy. Struct Integr Life. 2010; 10(2): 161-164. http://divk.inovacionicentar.rs/ivk/ivk10/161-IVK2-2010-AS-KC-ZB-ST.pdf.

Milovanović A, Sedmak A, Čolić K, Tatić U, Đorđević B. Numerical analysis of stress distribution in total hip replacement implant. Struct Integr Life. 2017; 17(2): 139-144. http://divk.inovacionicentar.rs/ivk/ivk17/139-IVK2-2017-AM-AS-KC-UT-BDj.pdf.

Milovanović A, Sedmak A, Grbović A, Mijatović T, Čolić K. Design Aspects of Hip Implant Made of Ti-6Al-4V Extra Low Interstitials Alloy. Procedia Struct Integr. 2020; 26: 299-305. https://doi.org/10.1016/j.prostr.2020.06.038.

Mijatović T, Milovanović A, Sedmak A, Milović Lj, Čolić K. Integrity assessment of reverse engineered TI-6AL-4V ELI total hip replacement implant. Struct Integr Life. 2019; 19(3): 237-242. http://divk.inovacionicentar.rs/ivk/ivk19/237-IVK3-2019-TM-AM-AS-LjM-KC.pdf.

Sedmak A, Čolić K. Fracture and fatigue behaviour of implants made of Ti alloys. Procedia Struct Integr. 2019; 23: 45-50. https://doi.org/10.1016/j.prostr.2020.01.061.

Čolić K, Sedmak A, Legweel K, Milošević M, Mitrović N, Mišković Ž, Hloch S. Experimental and numerical research of mechanical behaviour of titanium alloy hip implant. Teh Vjesn. 2017; 24(3): 709-713. https://doi.org/10.17559/TV-20160219132016.

Čolić K, Sedmak A, Grbović A, Tatić U, Sedmak SA, Đorđević B. Finite element modeling of hip implant static loading. Procedia Eng. 2016; 149: 257-262. https://doi.org/10.1016/j.proeng.2016.06.664.

Sedmak A, Čolić K, Grbović A, Balać I, Burzić M. Numerical analysis of fatigue crack growth of hip implant. Eng Fract Mech. 2019; 216: 106492. https://doi.org/ 10.1016/j.engfracmech.2019.106492.

Sedmak A, Kirin S, Martić I, Jeremić L, Vučetić I, Golubović Sedmak T, Sedmak SA. Structural Integrity and Life Assessment of Pressure Vessels - Risk Based Approach. In: Experimental and Computational Investigations in Engineering, Proceedings of the International Conference of Experimental and Numerical Investigations and New Technologies, CNNTech2020, Springer, 2020: 274–293. https://doi.org/10.1007/978-3-030-58362-0_16.

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Rakonjac I. (2018). Novel Risk Based Assessment of Pressure Vessels Integrity. Teh Vjesn. 2018; 25(3): 803-807. https://doi.org/ 10.17559/tv-20170829144636.

Kirin S, Jeremić L, Sedmak A, Martić I, Sedmak SA, Vučetić I, Golubović T. Risk based analysis of RHPP penstock structural integrity. Frat ed Integrita Strutt.2020; 14(53): 345-352. https://doi.org/ 10.3221/IGF-ESIS.53.27.

Golubović T, Sedmak A, Spasojević Brkić V, Kirin S, Veg, E. Welded joints as critical regions in pressure vessels – Case study of vinyl-chloride monomer storage tank. Hem Ind. 2018; 72(4): 177-182. https://doi.org/10.2298/HEMIND171009006G.

Sedmak A, Zaidi R, Vujičić B, Šarkočević Ž, Kirin S, Stamenić Z, Đukić M, Bakić G. Corrosion effects on structural integrity and life of oil rig drill pipes. Hem Ind. 2022; 76(3):167-177. https://doi.org/10.2298/HEMIND220222014S.ž

Zaidi R, Sedmak A, Kirin S, Grbović A, Wei L, Lazić Vulićević Lj, Šarkočević Ž. Risk assessment of oil drilling rig welded pipe based on structural integrity and life estimation. Eng Fail Anal. 2020; 112: 104508. https://doi.org/10.1016/j.engfailanal.2020.104508.

Kirin S, Sedmak A, Zaidi R, Grbović A, Šarkočević Ž. Comparison of experimental, numerical and analytical risk assessment of oil drilling rig welded pipe based on fracture mechanics parameters. Eng Fail Anal. 2020; 114: 104600. https://doi.org/10.1016/j.engfailanal.2020.104600

Chen, X.G, Wu, X.G, Yan, M.G. Dugdale model for strain hardening materials. Eng. Fract. Mech. 1992; 41(6):843-871. https://doi.org/10.1016/0013-7944(92)90236-8.

Lee, J-S, Ju, J-B, Jang, J-I, Kim, W-S, Kwon, D. Weld crack assessments in API X65 pipeline: failure assessment diagrams with variations in representative mechanical properties. Mater Sci Eng. A 2004; 373:122-130. https://doi.org/10.1016/j.msea.2003.12.039.