Numerical analysis of flow within a packed bed using computational fluid dynamics: Effects of fluid nature and regime Original scientific paper

Main Article Content

Abstract

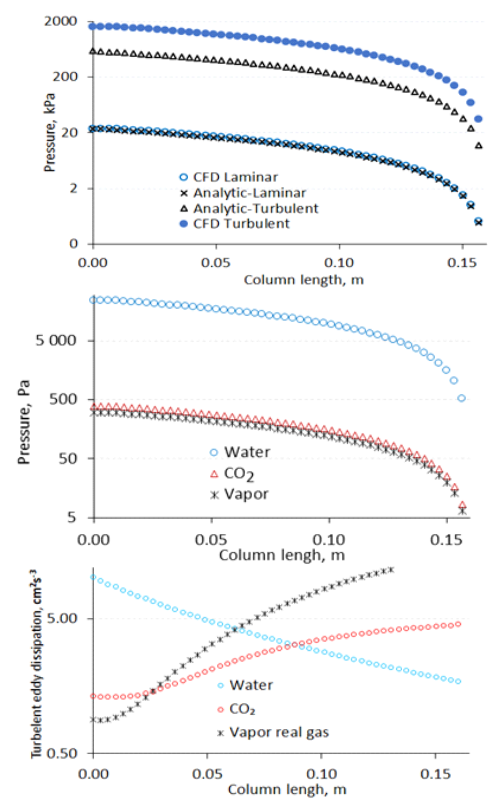

This research conducts a computational fluid dynamics (CFD) analysis comparing laminar and k-epsilon turbulent models of fluid flow through a packed bed. For this, three types of fluids (water, water vapor and carbon dioxide) were examined. The CFD model was initially juxtaposed with two experimental ones reported in the literature. It was observed that the numerical model used was in reasonable agreement with the experimental data reported in literature, provided that the packed bed dimensions (column diameter and height, grain size) aligned with those used experimentally. Thus, a decrease in pressure in descending order was noticed for the three fluids studied for both regimes from the column top to the outlet. In addition, a thorough characterization of turbulence was conducted, including determination of turbulent kinetic energy (TKE) and turbulent eddy dissipation (TED). As a result, a rapid dissipation of TKE for water was observed compared to the other two fluids, where TKE decreased progressively along the column length. In contrast, the TED for water decreases gradually until the exit of the column, while for both gaseous fluids, it increases slowly along the column length. The analysis of the vapor flow included testing of two density models, namely the constant density and the Peng-Robinson model. It was observed that the PR model for vapor properties showed similar trends of TKE and TED as those predicted for carbon dioxide.

Article Details

Issue

Section

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Authors grant to the Publisher the following rights to the manuscript, including any supplemental material, and any parts, extracts or elements thereof:

- the right to reproduce and distribute the Manuscript in printed form, including print-on-demand;

- the right to produce prepublications, reprints, and special editions of the Manuscript;

- the right to translate the Manuscript into other languages;

- the right to reproduce the Manuscript using photomechanical or similar means including, but not limited to photocopy, and the right to distribute these reproductions;

- the right to reproduce and distribute the Manuscript electronically or optically on any and all data carriers or storage media – especially in machine readable/digitalized form on data carriers such as hard drive, CD-Rom, DVD, Blu-ray Disc (BD), Mini-Disk, data tape – and the right to reproduce and distribute the Article via these data carriers;

- the right to store the Manuscript in databases, including online databases, and the right of transmission of the Manuscript in all technical systems and modes;

- the right to make the Manuscript available to the public or to closed user groups on individual demand, for use on monitors or other readers (including e-books), and in printable form for the user, either via the internet, other online services, or via internal or external networks.

How to Cite

References

[1] Dong X, Liu H, Chen Z, Wu K, Lu N, Zhang Q. Enhanced oil recovery techniques for heavy oil and oil sands reservoirs after steam injection. Appl Energy. 2019; 239: 1190-1211. https://doi.org/10.1016/j.apenergy.2019.01.244

[2] Zhou X, Wang Y, Zhang L, Zhang K, Jiang Q, Pu H, Wang L, Yuan Q. Evaluation of enhanced oil recovery potential using gas/water flooding in a tight oil reservoir. Fuel. 2020; 272: 117706. https://doi.org/10.1016/j.fuel.2020.117706

[3] Keyvan Hosseini M, Liu L, Keyvan Hosseini P, Bhattacharyya A, Lee K, Miao J, Chen B. Review of hollow fiber (HF) membrane filtration technology for the treatment of oily wastewater: Applications and challenges. J Mar Sci Eng. 2022; 10(9). https://doi.org/10.3390/jmse10091313

[4] Kumar P, Brar SK, Cledon M. A computational fluid dynamics approach to predict the scale-up dimension of a water filter column. Case Stud Chem Environ Eng. 2022; 5: 100201. https://doi.org/10.1016/j.cscee.2022.100201

[5] Brown GO. Henry Darcy and the making of a law. Water Resour Res. 2002; 38(7): (11-1)-(11-12). https://doi.org/10.1029/2001WR000727

[6] Shu X, Wu Y, Zhang X, Yu F. Experiments and models for contaminant transport in unsaturated and saturated porous media-A review. Chem Eng Res Des. 2023; 192: 606-621. https://doi.org/10.1016/j.cherd.2023.02.022

[7] Yan C, Fan H, Huang D, Wang G. A 2D mixed fracture-pore seepage model and hydromechanical coupling for fractured porous media. Acta Geotech. 2021; 16(10): 3061-3086. https://doi.org/10.1007/s11440-021-01183-z

[8] Amini Y, Shadman MM, Karimi-Sabet J. CFD simulation of flow distribution in the randomly packed bed Dixon ring. Sep Sci Technol. 2022; 57(12): 1900-1909. https://doi.org/10.1080/01496395.2021.2009513

[9] Lagrée B, Zaleski S, Bondino I. Simulation of viscous fingering in rectangular porous media with lateral injection and two- and three-phase flows. Transp Porous Media. 2016; 113(3): 491-510. https://doi.org/10.1007/s11242-016-0707-x

[10] Liu S, Liu L, Gu H, Wang K. Experimental study of gas-liquid flow patterns and void fraction in prototype 5 × 5 rod bundle channel using wire-mesh sensor. Ann Nucl Energy. 2022; 171: 109022. https://doi.org/10.1016/j.anucene.2022.109022

[11] Alhosani A, Selem A, Foroughi S, Bijeljic B, Blunt MJ. Steady-state three-phase flow in a mixed-wet porous medium: A pore-scale X-ray microtomography study. Adv Water Resour. 2023; 172: 104382. https://doi.org/10.1016/j.advwatres.2023.104382

[12] Liao Y, Zheng J, Wang Z, Sun B, Sun X, Linga P. Modeling and characterizing the thermal and kinetic behavior of methane hydrate dissociation in sandy porous media. Appl Energy. 2022; 312: 118804. https://doi.org/10.1016/j.apenergy.2022.118804

[13] Chen X, Zhao H. A phenomenological design method of the parallel packed bed reactors for chemical looping combustion of gas fuels. Chem Eng Sci. 2024; 292: 119988. https://doi.org/10.1016/j.ces.2024.119988

[14] Amini Y, Nasr Esfahany M. CFD simulation of the structured packings: A review. Sep Sci Technol. 2019; 54(15): 2536-2554. https://doi.org/10.1080/01496395.2018.1549078

[15] Wang Y. CFD simulation of propane combustion in a porous media: application to enhanced oil recovery of heavy oil reservoirs. Pet Sci Technol. 2020; 38(5): 432-439. https://doi.org/10.1080/10916466.2019.1705857

[16] Jiang Y, Khadilkar MR, Al-Dahhan MH, Dudukovic MP. CFD of multiphase flow in packed-bed reactors: II. Results and applications. AIChE J. 2002; 48(4): 716-730. https://doi.org/10.1002/aic.690480407

[17] Gao X, Zhu YP, Luo ZH. CFD modeling of gas flow in porous medium and catalytic coupling reaction from carbon monoxide to diethyl oxalate in fixed-bed reactors. Chem Eng Sci. 2011; 66(23): 6028-6038. https://doi.org/10.1016/j.ces.2011.08.031

[18] Macfarlan LH, Phan MT, Eldridge RB. Methodologies for predicting the mass transfer performance of structured packings with computational fluid dynamics: a review. Chem Eng Process - Process Intensif. 2022; 172: 108798. https://doi.org/10.1016/j.cep.2022.108798

[19] Wang G, Cai W, Xie L, Zhang X, Wang Y. CFD modeling and simulation of the hydrodynamics characteristics of packed column with structured sinusoidal corrugated sheets packings. Chem Eng Res Des. 2022; 183: 56-66. https://doi.org/10.1016/j.cherd.2022.04.038

[20] Peng J, Yu B, Yan S, Xie L. CFD Modeling and simulation of the axial dispersion characteristics of a fixed-bed reactor. ACS Omega. 2022; 7(30): 26455-26464. https://doi.org/10.1021/acsomega.2c02417

[21] Petrazzuoli V, Rolland M, Sassanis V, Ngu V, Schuurman Y, Gamet L. Numerical prediction of Péclet number in small-sized fixed bed reactors of spheres. Chem Eng Sci. 2021; 240: 116667. https://doi.org/10.1016/j.ces.2021.116667

[22] Pashchenko D, Karpilov I, Mustafin R. Numerical calculation with experimental validation of pressure drop in a fixed-bed reactor filled with the porous elements. AIChE J. 2020; 66(5): e16937. https://doi.org/10.1002/aic.16937

[23] Zhuang YQ, Gao X, Zhu Y ping, Luo Z hong. CFD modeling of methanol to olefins process in a fixed-bed reactor. Powder Technol. 2012; 221: 419-430. https://doi.org/10.1016/j.powtec.2012.01.041

[24] Amini Y, Karimi-Sabet J, Nasr Esfahany M, Haghshenasfard M, Dastbaz A. Experimental and numerical study of mass transfer efficiency in new wire gauze with high capacity structured packing. Sep Sci Technol. 2019; 54(16): 2706-2717. https://doi.org/10.1080/01496395.2018.1549076

[25] Mohanty R, Mohanty S, Mishra BK. Study of flow through a packed bed using discrete element method and computational fluid dynamics. J Taiwan Inst Chem Eng. 2016; 63: 71-80. https://doi.org/10.1016/j.jtice.2016.03.025

[26] Liu X, Peng C, Bai H, Zhang Q, Ye G, Zhou X, Yuan W. A pore network model for calculating pressure drop in packed beds of arbitrary-shaped particles. AIChE J. 2020; 66(9). https://doi.org/10.1002/aic.16258

[27] Ergun S, Orning AA. Fluid flow through aandomly packed columns and fluidized beds. Ind Eng Chem. 1949; 41(6): 1179-1184. https://doi.org/10.1021/ie50474a011

[28] Koekemoer A, Luckos A. Effect of material type and particle size distribution on pressure drop in packed beds of large particles: Extending the Ergun equation. Fuel. 2015; 158: 232-238. https://doi.org/10.1016/j.fuel.2015.05.036

[29] Wu J, Yu B, Yun M. A resistance model for flow through porous media. Transp Porous Media. 2008; 71(3): 331-343. https://doi.org/10.1007/s11242-007-9129-0

[30] Zeng Z, Grigg R. A Criterion for non-Darcy flow in porous media. Transp Porous Media. 2006; 63(1): 57-69. https://doi.org/10.1007/s11242-005-2720-3

[31] Ziółkowska, I, Ziólkowski, D.Modelling of gas interstitial velocity radial distribution over a cross-section of a tube packed with a granular catalyst bed. Chem Eng Sci. 1993; 48(18): 3283-3292. https://doi.org/10.1016/0009-2509(93)80212-9

[32] Zou Y, Gu H, Huang A, Zhang M, Ji C. Effects of MgO micropowder on microstructure and resistance coefficient of Al2O3-MgO castable matrix. Ceram Int. 2014; 40(5): 7023-7028. https://doi.org/10.1016/j.ceramint.2013.12.030

[33] Khalladi R, Benhabiles O, Bentahar F, Moulai-Mostefa N. Surfactant remediation of diesel fuel polluted soil. J Hazard Mater. 2009; 164(2-3): 1179-1184. https://doi.org/10.1016/j.jhazmat.2008.09.024

[34] Matsson JE. An introduction to ANSYS fluent 2022. SDC Publications; 2022. https://www.sdcpublications.com/Textbooks/Introduction-ANSYS-Fluent-2022/ISBN/978-1-63057-569-4/

[35] Baker TJ. Mesh generation: art or science?. ProgAerosp Sci. 2005; 41(1):29-63. https://doi.org/10.1016/j.paerosci.2005.02.002

[36] Hossain MA, Nabavi SA, Ranganathan P, Könözsy L, Manovic V. 3D CFD modeling of liquid dispersion in structured packed bed column for CO2 capture. Chem Eng Sci. 2020; 225: 115800. https://doi.org/10.1016/j.ces.2020.115800

[37] Yang B, Yang T, Xu Z, Liu H, Yang X, Shi W. Impact of particle-size distribution on flow properties of a packed column. J Hydrol Eng. 2019; 24(3). https://doi.org/10.1061/(asce)he.1943-5584.0001735

[38] Erdim E, Akgiray Ö, Demir I. A revisit of pressure drop-flow rate correlations for packed beds of spheres. Powder Technol. 2015; 283: 488-504. https://doi.org/10.1016/j.powtec.2015.06.017

[39] Linsong J, Hongsheng L, Shaoyi S, Maozhao X, Dan W, Minli B. Pore-scale simulation of flow and turbulence characteristics in three-dimensional randomly packed beds. Powder Technol. 2018; 338: 197-210. https://doi.org/10.1016/j.powtec.2018.06.013

[40] Papkov V, Shadymov N, Pashchenko D. Gas flow through a packed bed with low tube-to-particle diameter ratio: Effect of pellet roughness. Phys Fluids. 2024; 36(2): 027127. https://doi.org/10.1063/5.0183475

[41] Lopez-Echeverry JS, Reif-Acherman S, Araujo-Lopez E. Peng-Robinson equation of state: 40 years through cubics. Fluid Phase Equilib. 2017; 447: 39-71. https://doi.org/10.1016/j.fluid.2017.05.007

[42] Paterson L, Lu M, Connell L, Ennis-King JP. Numerical modeling of pressure and temperature profiles including phase transitions in carbon dioxide wells. SPE Annual Technical Conference and Exhibition, Denver, Colorado, USA: Society of Petroleum Engineers, 2008, paper SPE-115946-MS. https://doi.org/10.2118/115946-MS

[43] Lv J, Chi Y, Zhao C, Zhang Y, Mu H. Experimental study of the supercritical CO2 diffusion coefficient in porous media under reservoir conditions. R Soc Open Sci. 2019; 6(6). https://doi.org/10.1098/rsos.181902

[44] Skjetne E, Auriault JL. High-velocity laminar and turbulent flow in porous media. Transp Porous Media. 1999; 36(2): 131–47. https://doi.org/10.1023/A:1006582211517